I would have guessed they somehow used baling wire. However, it is the first time in a =very very= long time (decades) I could not find a google reference (muchless a youtube video) on how to do something that is seemingly a SHTF skill. ![]()

I am not sure the video isn’t right… it is pointing to a cooling/discharge issue. Which according to milwaukee their 'REDLITHIUM™ High Output HD12.0 Battery Pack: Provides 50% more power and runs 50% cooler versus standard REDLITHIUM™ HD packs. ’

So get the saw with the new pack (which may have active cooling ie a fan) and you can use it in all your tools, but don’t use the old packs in your saw. They aren’t big enough or cool fast enough when delivery as many amps as the saw needs.

Hi All,

I am transfering this over as I realized I had been putting up electric chainsaw videos in three different places:

And searching to add one more that I thought was very relevant.

Ahhh . . .here

Watch clear through to see a lot of up in the sky climbed up working younger-mans game and even large gasoline saws working too. Needs-must taking down a large tall become hazard trees into a small space, a limb and section at time.

Ha! Ha! And you will get to hear him curse the Stihl electric system a lot.

Look for these types of guys working in real life. Sit back and watch. A hell of a lot more fun watching than any stadium sports I think.

S.U.

I changed the bar and chain on my greenworks to an oregon bar and chain. The chain is smoother and a bit quieter then even when the saw was brand new. it seemed to bounce around less. I have to get into some brush to know for sure.

actually i think about electric chainsaws…, the watts on the nameplate…is this reffered to the output watt of the tool?, and if it is so, how approximately one could calculate the electric input needed?

excuse my stupid non expert question, but , for example i have bought a small electric compressor with 500 watt , but the input must be much higher, my small genset with 2000 watt on chargas not can handle it, and the bigger genset with 3000watt can it run only on lowest rpm…on chargas…( i know 1/3 is power loss on chargas approximately)

Giorgio, that’s a tricky question. It’s like asking - how long is a string? ![]() While coffe makers or electric radiators have fixed input power - any rotating applications are all over the place.

While coffe makers or electric radiators have fixed input power - any rotating applications are all over the place.

With very little load there’s very little electric power needed, but in general you calculate startup power to be rated power x 3. True for compressors, or anything with some flywheel action built into it.

It is probably the max designed output or 500 watts divided by voltage(220?) = running motor amps. It can be 2x-5x startup surge or more input current (amps) on startup depending on the motor type.

Since chargas is thrown into the equation, you might want to check how much current you are actually producing. It might be closer to 40% of nameplate or less then half.

You might be running into part of the issue of why people feed the generator power into a battery bank. Then use an inverter to run their equipment.

If you are getting enough amps to maintain the nameplate wattage of the motor. Then you can look at a soft-start module, which reduces the 2-5x initial current draw, by lowering the initial voltage then ramping it up over a couple of seconds to get to full speed. Something like this (and you will probably want a heatsink too).

I too have ran into problems trying to run my small air compressor on the Wife’s Honda 2000 inverter-generator Giorgio.

Even on full power gasoline it want to try, and try, and try; but will overload disconnect itself.

Our problems are three ways.

Out little systems have no automatic unloader valves like a big commercial air compressors systems. Like most designed to be directly engine driven air compressors have too. So we must power the electric motor up to operating speed (where its watts or amps are rated) AND power immediately pumping air.

Second the compressor maker thinks these will be Grid electrical circuit supplied. Then able to 3X, 4X surge draw to get started and up to working speed against an air-compressor loading.

Third we are actually asking too much of these small inverter-gnerators.

A pulley driven air compressor you could set up with longer belts and a manual swinging tensioning pulley. Disengaged while the motor is coming up to operating speed. Then engaged to pump air after motors is up to speed.

Sigh. Mine is a direct driven diaphragm, oil-less type.

Here is want limited use works for me.

I manually open up the overpressure relief valve. Lock it open. Turn on the air compressor electric motor being inverter-gnerator supplied. Only after everything is up to speed and stable . . . only then flip the air relief valve closed.

Still I can only get up to 100-125 PSI on my 175 PSI air compressor system before the inverter-generator overloads kicks out.

And it will only restart off of the generators power once the system air pressure has dropped below 50-60 PSI.

We simply need larger inverter-gnerators for loaded electric motor usages such as Air compressors; Water well pressure pumps; Others.

I did then buy a 2800 watt Yamaha inverter-gnerator hoping to power my air-compressor . . . it does worse.

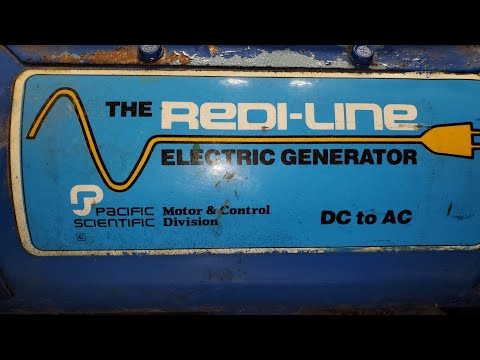

Yet a 1600 watt rated RediLine motor-generator will start up and run the air compressor. It has a 1 second 3X; then 2 seconds 2X; tapering down to 1.5X surge for a few minutes.

And to get these you have to trick it into up to full operating speed with first an at least 40 watt incandescent light bulb load. Have BIG battery cables. And one BIG; or two large batteries.

Sorry. There are no easy maths to real world true applications.

Well . . . except to 3X, 4X oversize. Then learn by doing.

Regards

Steve unruh

Hello Giorgio, our friends wrote well that starting the compressor is quite demanding, it needs a lot of torque to move the piston and rotate it. These small compressors also have high revolutions (3000 rpm), which means that the drive electric motor is also with high revolutions and low torque, so a short-circuit current actually flows through the winding when starting, probably the current with a 500W motor would reach 16A for fraction of a second, which means a power peak of more than 3 kW. The problem is not that the drive motor for the 2kW generator has insufficient power for this peak, as it has a lot of kinetic energy stored during operation due to inertia, the problem is in the winding of the generator, which is not capable of producing such a large current, it probably only reaches 10A. When I tested my 5kW three-phase synchronous generator, I reached full power by connecting the heaters, approx. 8A after each phase, well, starting the 3kW three-phase motor for crushing corn gave it great problems. At the first opportunity I will try to connect a 1.5kW single phase compressor to my 5kW asynchronous motor/circular saw generator, I have a feeling it will do it easily (but I could be wrong).

Very nice review and use of electric saws the professional way. I cut conifers a few weeks back, almost got killed with cutting the first one. Watched a lot of video’s of these guys and put the rest exactly were they supposed to fall. Work was done with the 535i. Bought a few months ago, hesitating for the Ego tools but all my tools are Husqvarna. Difficult to switch, that means all new batteries. After this work I am really happy with it and compared it with the Ego from my friend. Ha, batt are way better, cutting quality the same.

Taking 30ft/10m off and leaving 24ft/8 m standing. Respect for the guys doing this for a living. I am afraid of hights and chainsaws. How studpid to start cutting this high? Wet pants all day. ![]()

Anyway, besides the noise and smell the starting of a batt powered saw is a big big plus. No more pulling a rope.

Now a lot of wood has to get moved. For the Scandinavian guys, a Timan Tool-Trac? Is this a durable machine? Any parts available? Very rare overhere and no dealer anymore.

Apparently there is a new 5.8hp Greenworks commercial saw on it’s way. It is roughly equivalent to the Husqvarna 572 XP. If you scroll about halfway down the page, they have it listed in their chainsaw line up.

So 82 volts x 4 amp-hours = 248 watt-hours. 248 watt-hours / 3400 watts = .074 hours = 4.34 minutes. The saw won’t be working at 100% all the time, but that doesn’t seem like much operating time. I wonder about the numbers, taken together. Maybe I’m missing something?

It is actually 328 watts but still basically only 5.8 minutes of actual cutting time unless there is some automatic variance with the load which I doubt. But if the chain jumps off the sprocket it stops immediately so it has to be detecting that.

They make larger batteries but that does add expense. But that battery only takes like a half hour to recharge. but it is still make a few big cuts then do limbs… charge it, then clean up while you are waiting. Which isn’t an ideal workflow, if you aren’t close to the house or in a huge hurry.

Four times eight is thirty-two,

Four times eight is thirty-two,

Four times eight is thirty-two,

Four times eight is thirty-two,

![]()

I don’t know if it fits in this thread?

But i got my hands on another chainsaw, electric, (cord) this one is extremely heavy duty, strong, and built to be easy to service/repair.

Almost all metal, based on a industrial quality angle grinder.

Altought being electric, i like it, loud and heavy as i want my saws

As i post it here, what i have in mind: an old lawn tractor, a 240volts 50hz generator head, and a charcoal gasifier

It is a nice find!! What I was thinking looking at the pictures was a robotic arm in front of a remote controlled tracked vehicle.

Never seen anything like it but that grinder looks a lot like an old Black and Decker industrial grinder. You had to be sporting significant ballage to spend a day with one of those. ![]()

“A robotic arm in front of a remote controlled tracked vehicle” i got the feeling you watch too much science fiction Sean?

Just kidding, i like the idea, but remote control takes away much of the fun ![]()

Oh I completely understand, I just don’t run as fast as I used to. ![]()