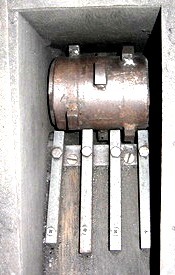

Charcoal Grinder - First Test

I decided to test the grinder at 12V first, so that it would be going a little slower.

The first test went OK, but was a little disappointing.

In particular, the grinder choked several times with the first few handfuls of charcoal I put in it.

A little investigation revealed that I had randomly selected the last 5 gallon bucket from the first batch of charcoal I had made. This would have been the very last of the charcoal out of the retort, which would have been located in the top of the retort during the burn. As I commented previously, I found the most torified wood in this region, and from that burn. And, sure enough, it was choking on the occasional “solid” piece that was not fully charred (even though it might look charred on the outside).

I switched to a bucket from my second batch of charcoal. It digested a few handfuls of this fine at 12V. I decided to kick it up to 24V. It was noticeably faster. I processed a 5 gallon bucket of charcoal in just a few minutes.

After screening, this is what the “fuel” charcoal looked like.

I don’t know if you can see it in this picture, but I think that there are some fines in the dust tray that are big enough to use for fuel as well. I think I need to tighten up my small screen a little bit.

Anyway, I am very happy with the results. It looks like the grinder will produce fuel quality charcoal a lot faster than I can make it. It should work fine for what I have in mind.

The grinding and screening process does make quite a bit of dust. I think it would be better to do that outside.

I can also see the need for some sort of simple screen shaker; or an arrangement like Don’s.

Anyway, a big thanks to Gary for sharing his design, and Don for inspiring me to try this method.