Hi there Al and thank you.

I paid $9000 for 4- 260W Panels, 4000 W inverter, a Midnight controller, racking, 8 batteries and installation.

Knowing what I know now, I could do this myself and could save $3-4000.

My new generator should be here tomorrow. It’s a 10K with a Perkins diesel.

Is it worth it? When I drive 3 miles into the woods and I have all the power I need and not dependant on a power company, I say “Yes”. I have a couple other generators that can back up the main one, it will just take longer. In a year I will charge my battery bank up on wood.

The best days are when the sun shines. A day of sun and no generator noise is a good day. To hear just the animals and the leaves in the wind is amazing and I can still turn a light on.

Cabin is looking great Bill, congrats on the new genny that will be a great asset to you. I just picked up a used 15 kw 4cyl tri fuel Onan 1800 rpm set. Bet you can’t guess what the 4th fuel will be. I have to get to Hayward this week and pick up my new panes too. Like you I can’t wait to turn on the lights without the noise. My sun exposure here be poor though out the winter when the sun is low. Lots of trees I don’t own and lots of cloudy short days. Keep on keeping on.

Are you running every thing off of the inverter ? or do you have lights, or other things on DC, 12,24 volt?

Thanks Jim.

Yeah, I need pictures of your power plant.

@trikebuilder57 I run everything on AC power

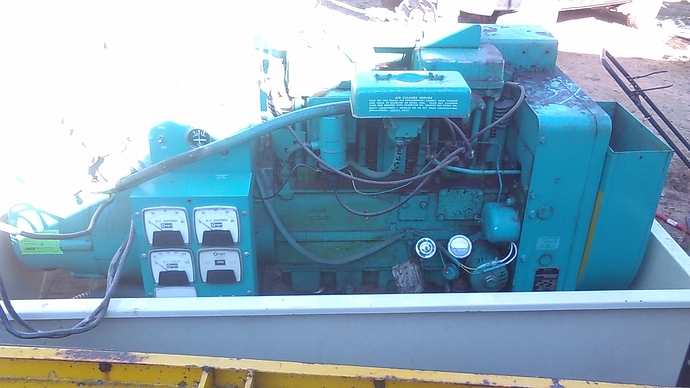

I haven’t gotten it unpacked yet, but here it is. Trailer and switching gear came with it. 514 hours

What you have there is one of the J series ( I think ) .

Probably among the very best engines of its type ever made ( Studebaker Packard corp era ).

Treat it like crystal drinking glasses or fine China and it will last you the rest of your life.

Abuse it and people who collect engines like me will haunt you in you dreams lol…

500 hours is very little.

This engine will last forever if you are careful.

Magneciters are near in foul able…

The engine itself has some quirks but mostly related to ethanol gas issues.

Lucky fellow, I would like to have that.

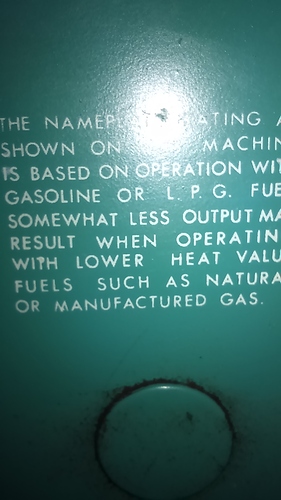

This one has never tasted gasoline. It has inhaled propane it’s whole life. Yes it is a 15 ojc and jus barley broken in If the hobbs meter is correct. Valve cover gaskets appear to have leaked an awful lot for that few hours since 1974. No signs of rodents or excess heat on my pre use checks. Kindof over kill for my needs but at a 50% derating for wood gas it will still exceed my needs

Not going to mess around this winter. They are talking about it being pretty severe. I dipped into my retirement to get this beauty. I wasn’t thrilled to have it dangling from my bucket the 50 yards to bring it to my shed but I was successful without incident.

I installed a couple of 2x6’s to my top plate to hang my chain hoist from.

So, I want to utilize the waste heat from the cooling system to circulate through my floor. Some on here have explained how getting the engine too cold may be damaging to the engine and/or make it inefficient. These red flags I understand but not being and engine guy, I don’t know where to place the out going and incoming line to prevent an engine cool down.

If you look between the cage and the engine, there appears to be a ½" hose too that the coolant goes through.

Good idea on useing exess heat.

I think this shuldnt be a problem. My father has floor heating hooked on a wood stove, there is a adjustible mixing valve in between not to alow more thain 24c in the floor pipes and the stove to always operate above 60c to avoid acetic condensate eating the heat exchangers. You shiuldnt have much problems, just swich the wood stove with the engine.

Yes,

Kristian is right. I use a simular 3-way thermostat in my boiler setup.

If the engine has a thermostat and a radiator, the excess heat from the engine can be taken off after the thermostat and before the radiator and then the floor heating coils will do the work of the radiator. The thermostat is there to keep the engine at operating temperature. If you take heat off before the thermostat, the engine might not get up to operating temperature for a very long time and thus not operate at optimum temperature range and efficiency.

Bill, I would do as Don said, and use the floor as the radiator, but would monitor the temp. closely with an auto type gauge. Or, you could build a heat ex changer on the exhaust, circulating water with a little anti freeze through a pump. Keeping the temp. up on a diesel is a must, they will wear prematurely if run cold, and not be as efficient. Al

Well BillS by the picture very clearly from the water temperature electrical sensor in the side of that engine outlet housing as DonM said there has to be a mechanical engine coolant flow control thermostat in there.

Your 1/2" hose out the front side is a coolant by-pass flow house for coolant to be able to flow with the thermostat closed. Other wise you’d make steam bubbles in the cylinder head.

The 1/2" pipe plug comming out the brass sensor side of the outlet housing would be for an auxiliary cab heater hot-side flow source.

Decision time for you.

IF you tee into the big flow hose from the outlet housing to the radiator and you may never get any slab heat flow on really cold winter days. Thermostat may never need to open.

IF you directed ALL engine coolant flow then you may engine overheat on some days with the slab unable to take out enough heat. Thermostat open all of the time.

Me?

I’d go with the 1/2’ side outlet flow with a manual control valve opened j-u-s-t enough.

One setting for Cold conditions.

Another for COLD, COLD conditions.

Shut off when slab heat not needed.

Just like a vehicle cab heating system.

You are gong to find warming up time benefits from air flow blocking the front of the radiator in COLD, COLD.

You could benefit from taking off the engine driven cooling fan and puting on a thermal switched controlled auto radiator air puller/pusher fan.

See . . . the more complexity “automation” you add, the more to set up, maintain, wear/fail, then diagnose, and repair.

The more manual steps you add, the more to forget when distracted, tired, cold and wet.

Regards

Steve Unruh

I wonder bill if you could not run a second radiator in front of the generator’s one to act as an air to liquid exchanger for the floor maybe teamed up with another one for the exhaust. My thinking would be you will be tampering with a new possibly warranteed? Unit which might not be advised yet. Another simple slab heat option is to install a baffle in front of the fan and exhaust and point them at 45 degrees towards the ground. Random thoughts…

I think the mixing valve shuld not be avoided. If you just change the radiator with floor heating, the coolant is far to hot entering the flor pipes. You will burn your feet on the first few turns but thanin the pipe will run cold.

The mixing valve is here to make sure the water circulates fast at lower temperature, a few degrees above wanted room temperature, so that the temperature is eaven.

I know a guy who tryed to do it without the mixing valve for his bathroom. He ended up marking the cheramic plates that first got the heat, not to step on them. Blistering hot.

As for exhaust, l wuld jus make a copper pipe heat exchanger inside or out of the exhaust pipe (not the original) to draw the heat out.

I don’t think there’s any possible way the floor can get too hot. The concrete is 5 1/2" thick. We had a mild winter last year and was down to -25F a few times. At least 3 months of the winter was spent below zero. Worst case scenario the generator will run 2 hours in the morning and 2 hours at night. I’m hoping to achieve floor temps of 30 F.

Bill if you do use the pipes in the floor you will need the mixing valve. Pex is rated at 180 degrees only. I don’t think it would fail with so much concrete around it but why push it. There are boiler mixing valves which automatically combine some returning cold water with the hot. The books say a faster moving warm liquid will out transfer a hotter slow moving one. I know in our slab hotspots were real when I was runing 140 water. I’ve dropped it down to 105 to 120… much more even now.

Best regards, always interesting!

David Baillie

So, this would mean I would need a couple of thermocouples so I know my in going and exiting temp, right? I could tee them with a 1/2" galvanized tee and use this thermocouple.

http://www.ebay.com/itm/Engine-Coolant-Antifreeze-Water-Temperature-Sending-Switch-Sensor-1-2-NPT-/201549937072?hash=item2eed4ff9b0:g:gRMAAOSwr7ZW8Wwv&vxp=mtr