Jumpers to cross over other traces, or a design change.

.84 for Run 1

.82 for Run 2

It was reading .6 with incandescent bulb.

There’s probably something flaky with the meters. Power factor for an incandescent bulb should be 1, or very close. Run one is iffy, with 126 watts AC input and 409 watts DC out (more than iffy ![]() ). Run two is possible, but DC voltage 1.6 times the AC voltage is pretty high, even allowing for RMS vs Peak-to-peak voltage difference.

). Run two is possible, but DC voltage 1.6 times the AC voltage is pretty high, even allowing for RMS vs Peak-to-peak voltage difference.

Yes, Jumpers as confirmed by Sean and Kent. They use the form of a resistor because they can use the same automated component insertion machines to install them, and wave solder with the rest of the board. (less human labor). note they select a 50 or 60 Hz configuration. ![]() “Marine” inverters are usually built to a high-quality standard.

“Marine” inverters are usually built to a high-quality standard.

EE here… 100% what Mike said.

I want to show how I’m cutting now.

I swapped out the marine inverter for a 2500watt Cobra and connected it to a marine lead-acid battery. From the inverter power goes to a bridge rectifier on top of the cart with a capacitor and from there it’s DC power into the spool. I replaced the 16" bar on the electric saw with a 10" and narrow chain. It’s narrow enough to be flexible in the cut and very handy for triming branches. I use the gas saw for cutting trunks and my PPE is in the black case hanging between the saws.

I’m pleased with this set-up. Although, I think it could be simpler by modifying the inverter instead of rectifying the output. But, it’s cutting good and using about 700W according to the inverter.

I would aim for efficiency with electric, an Alaska mill setup is far from energy or time efficient. You have gone with narrow kerf chain, that’s good, the logical low hanging fruit. The trouble with any chainsaw ripping is the teeth are not at all optimal for ripping, they are meant to crosscut. A far more efficient approach is to cut freehand with the nose of the bar at about a 30° angle with rapid shallow cuts always working backwards. I will credit this Russian fellow with the idea.

It works well, but requires skill, and the cuts will not be quite perfect, but it’s a better way to make rough lumber than an Alaska type mill. It’s far more versatile as there’s no gear to carry or need to move the log. It works even better in snow, as the snow will hold the log steady and off the ground. You also risk overheating a saw under a steady load, best to work in lower air temps and not at max revs. Possibly use a richer 2 stroke mix than specified, I always do anyways. I have figured out the best way to mark a line is with mason string, lay it out so you cut beside the line an inch or whatever, far better than a chalk line mark.

They make a chain meant for ripping but this saves buying a different chain.

Cutting using the edge of the nose of the bar is like night and day, it kicks out chips over an inch long. It’s a different concept, it’s basically routing. The only things that lead me to having issues (gouging the lumber when the bar leans sideways), is not having the patience to go easy on the depth of cut. If you ever get into a sawing situation it will gouge. It can be a little tricky keeping the cuts parallel, you have to be mindful of keeping the cut vertical. Obviously the first marking cut is pretty shallow, then you establish the groove in another pass or two, then you just let the nose swing back and forth, on the pull back you can really feel the cut. The chain has to be sharp. If not there will be problems with the cut, plus it wastes time, fuel and work. Knots will tend to throw off the cut if the chain isn’t sharp enough, or if you put too much pressure on the cut in the denser wood. I can slab 2 sides of a small 16’ aspen log in about 20 minutes using a bit over half a tank of gas. It’s a very handy trick if there was a log back in the bush somewhere hard to get at or if you need some timbers. Obviously length is unlimited, so you can customize roof beams.

It still blows my mind that you can rip logs with the tip. I wish i knew that trick when i bought my Alaskan chainsaw mill. I learned i like milling lumber because of one but i would never use one again. I would definitely try your trick first. That is if i didn’t have my bandsaw mill.

Looks like the guy, couldn’t handle the vibration of the gas saw and switched to electric. But he came up with a neat propelled cutting system.

Huh? I don’t see any milling set up.

I prepare my saw

Getting ready to cut, but it won’t be soon…

I have this saw motor which will run at different rpms based on the AC Hz.

I’m still interested in modifying regular 12V inverters so I can use it in the field at higher speed. I will post results when I try adding an aftermarket PWM to my inverter.

Thanks

Quick update to the thread.

I spoke to my lawyer. He told me I need to notify everyone with in 24hrs that the previous post was a false flag operation. So, this is your notification.

The weather is starting to break and I’m heading out more to work in the field, unless there is another cold snap I probably won’t be figuring out the 12V inverter trick this year.

But, I did invent this computer / cellphone workstation in the meantime:

And, it’s for sale! Made from pine trees that fell in my yard and red oak I brought from the local sawmill.

The price is 60 (USD/CHF/EUR) DM me and I will gladly send one out.

Thanks again everyone and have a nice spring season ![]()

Hey JoeSPA,

Please clarify specificaly your warning, “the previous post was a false flag operation”.

Your post #51 just before this one #52? That would be non-sensical. Unless you are saying it was not done by you. Or your submission was hacked and visually modified. The actual flags. The hydraulic motor driven bar-saw.

Or, the two post references to Advoko MAKES videos on posts #50 & #47 you are calling out as False Flags ?

If this is so you should Flag them for moderator attention with the checked box explanation of your complaint of these been put onto your topic.

Or are you saying your whole topics of varying the supply frequency to intending to improve electric motors power was a false flag operation?

Because if you have something hardware to sell you need to put it up in the For Sale topics category as all others do.

Steve Unruh

It’s gotten cold outside, and when I say cold I mean nearly single digits. What am I gonna do about it?? Make Apple Jack cider ofc!

So, here I am taking shelter from the cold and sipping Apple Jack. I’ve been catching up on the DOW-forum last few days and I’ve seen some more interesting topics (metallurgy and water-quality) and I’ve seen some more cool websites that look like from the 90s.

I write to update everyone on my progresses since last winter.

First of all, I lost 35lbs this year while studying the topic of RAW Food Nutrition in an online class. https://rawfoodeducation.com/mastering-raw-food-nutrition/

Nutritional Education was an issue I knew I needed to address and I’m glad that I did it. I earned a certificate from their “Mastering Raw Food Nutrition and Educator Course.” It’s not like I have a Masters’ Degree, but I am considered a master of RAW Food nutrition now and, I’m happy to answer questions on that topic.

As you may recall from my last winter posts in this thread, a storm blew a pair of trees over. One pine and one maple.

After cutting the pictured hydra-tree that split 4 times growing up and had 5 trunks (talk about dense energy storage), I dried the slabs in the shed over this past summer. This season I can work air-dried lumber in a warmed garage sipping a Sprite made with real sugar (not corn syrup) and I have made a few tools and gizmos that I’d like to offer for sale:

Small-Gasifier-Model: This down-draft reactor comes to a 1/4" restriction and requires suction/pump to start.

Teleconfrence-Phone-Holder: Clamps to a table or beam with a desk-clamp to hold your phone+accessories out

Single-hand-Saw: Has a thiner flexible blade. Handle is red-oak.

Both-hand-Saw: I’ve made a few iterations but this is more-or-less what I keep at hand when I’m running the chipper to deal with branches that need cut to fit in the machine. That’s a 1" brass ferrule that is clamping a Swiss-made 9" 8tpi reciprocating saw blade in place. The blade is also a bit thicker than normal recip. blades and the teeth are hardered.

On Metalurguy: I dont know much about the topic, but I’m curious to learn from someone with ‘first-hand’ knowledge. I noticed that the teeth of these Swiss Made Bosch Demolition blades are much harder than the back of blade as I was cutting a blade in half with my bandsaw: The saw easily cut thru the back of the blade until it reached the backside of the teeth then the bandsaw’s teeth started bouncing off the metal rather than cutting it. That section of metal would not cut, but it snapped off with a hammer blow. How is this possible? Is this from tempering the metal with heat? Is the process essentially to make the metal brittle? Or an alloy of different composition could have similar effect? Any info on the topic is appricated. If your explain makes sense to me I would gladly offer you one of my hand-made hand-saws, phone-holders, or bench-top electronics testing equipment as token of my appriciation.

Regarding the direction of the thread going forward:

As you know, my expiremnts modifying inverters to run my chainsaw more effectively yielded only limited success. I say that because I was not able to control the speed of the motor as planned. That said, the set-up I made on the A-Frame cart to run the saw with DC is still cutting good with the caviat that the chainsaws’ brushed electric motor occasionally trips the inverter’s over-current-protection on cold-start and then a re-start of the inverter is required.

I know my topic is only tangentially related to wood-gassing, but I feel I need to build my workshop before I can begin to work on the WK Gasifier or Dakota Pick-Up. And, to build the workshop I need tools and power. So, it’s part of the journey for me: Thank you for reading my messaage, and thank you for consideration.

I have re-viewed your comments on this thread. I really took Steve’s advice on batteries to heart:

However I was not sure if he meant to bank heavy 12Vdc batteries in parallel or series. If he mean to bank 12V lead-acid batteries in parallel then there would be twice as many cells as needed to reach the required voltage. Hey Steve, is there some benifit to have twice, or three times as many cells as nessisary?

I could not think of any reason for that. The most interesting interpretation of his statement that I could think of was a requirement for a ~mass of battery/batteries~. I think it is more correct to say a certain surface area of lead plate and a volume of battery acid are required to reliably output power at that level. And, it is my understanding that batteries specification includes Cold Cranking Amps (CCA) that is the relevant measure with what Steve is talking about. That if the battery can handle the amps while cold, once it warms up the load will be easier, no?

I assembled a battery bank pictured below from 6x 2V single-cell flooded lead-acid batteries. These batteries are sold with 20year guarantee and made of clear plastic so you can see the lead-plate and acid. During that time maintaince will be required to balance the battery. Each battery/cell has a removable cap for that purpose.

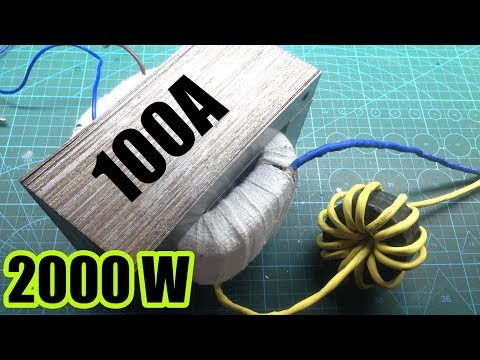

But, the piece is not complete because I am planning to add a DIY inverter to the battery bank skid following this simple example because in the video (@ 5min) he shows how to adjust the AC frequency from 20 up to 60hz:

I plan to replicate his device because although my corded chainsaw’s (brushed moto) speed will not be correlated to the AC Hz of the inverter due to motor’s design: his inverter doesn’t have any over-current-protection circut. And, the problem I expirence with my set-up is that over-current-protection on my Cobra brand inverter often trips when I am cutting with the chainsaw. If I baby it, and don’t press the saw into the wood it will continue to cut without interuption. But, if I try to to use the chainsaw dogs to lever the bar into the cut it will break the ciruct. So, I’m looking for a more rudamentary / robust ~driver~ for my power tools. I don’t want to use the word ~inverter~ because the brushed motors run better on DC. Ideally, ~the device~ would supply higher voltage DC rather than AC to a brushed motor. I think it should be possible to use back-EMF to determine the RPM of a brushed motor, then vary the voltage supplied to the motor to control the brushed motor speed. I’m imagining a single device that can be used to generate ~1.5kw power from a 12V car battery and control the speed of electric motors by either method: Hz or Voltz. Therefore, a multipurpose device for driving both motor types. Also, a “auto-soft-start” or something to reduce large current spikes without breaking the circut, and low battery cut-off.

Like in the video, there would be an Integrated Circut (Chip) or Printed Circut Board (PCB) as a “brain” which contains the device’s logic+features and drives the high-current-circut of the transformer.

My plan is: once the PCB design is paid for, we will have an affordable DIY circut that can accomplish the goal of driving both types of motors well at variable speeds with an inverter-style-configuration as shown in the InverntorKR video. (NO BUCK-BOOST STUFF, No additional PWM, stimble and robust design)

I’ve reached out to some YouTube electronics engineers about the possibility to develop such a device and I’m offering payment for time, expertise, and relevant information on the topic. If you know someone who is really smart about power electrics, please introduce them to my plan. Based on what I’ve seen the total cost of this DIY project should be a few dollars in parts and a few dollars for a PCB assuming you can come up with your own transformer (like shown in the video).

Hey JoeSPA good to hear about the newer, healthier you.

I am trying to answer your batteries in parallel or series to me.

First a battery is any number of cells set up ‘usually’ in series to increase thier combined output voltage. From a simple two cell flashlight and up.

Now a battery “bank” meaning pre-made cells groups banked up can have series-cells-groups in parallel. Or in series. Usually both arrangements done like in EV car “battery banks”.

Always with a unitized battery group of cells will be cell to cell charge balancing. One going quickly high voltage on charging can cause the group charger to cut back and even quit charging. One cell becomes internally low grade shorted will self discharge causing the whole battery to underperform. Then the whole battery to act weird on charging. A higher grade internal shorted cell will cause the other in-series cells to dump their power into it. Overheating it. Boil the electrolyte on a flooded type. A dry or paste type battery to overheat to open combustion. Combusting anything combustable in its construction. Lithium metal once burning wants to keep burning until all the lithium compound is oxidized converted.

VERY GOOD you picture up a stand alone, remote cell bank.

Suggest you rebuild it to allow for full top of access to each individual cell.

To be able to pull out a single cell gone bad boiling off electrolyte.

To be able to isolate and rebalance charge an individual cell gone stubborn to a general-for-all charging.

For the rest of your pursuit I cannot help you much.

Others will I am sure.

Regards

Steve Unruh

If the over-current protection shuts down your saw, that’s a good thing. I would trust the manufacturer on that, and go with an inverter large enough to handle the load. It’s also possible that it’s the low battery cut-off that’s shutting the inverter down. 1.5 kw is a fair load at 12 volts, like 125 amps. If you don’t have serious cables and connectors (~1-0 awg wire), the resistive voltage drop in the 12 volt wiring will reduce the inverter input voltage and shut it down.

edit: If you can put a voltmeter on the inverter input, and load the saw down, you can tell what’s going on. A lot of inverters shut down at 10 to 10.5 volts. You can also measure at the battery to see how much you’re loosing in the cables.

I looked back at your saw, and I think it’s rated at 1600 watts. If your inverter has a similar rating, and it’s the current overload you’re tripping, make sure you’re not overheating the saw also.

What you describe is an unbalanced battery that with out any maintainance will drain itself more rapidly and have a short life. Some lead-acid batteries I got during COVID only lasted two-to-three years before they need to be recycled. And, I understand there is a lead-acid battery recycling industry that in theroy could profit from the mismanagement of these lead-acid battery cells, by rebalancing the bad cell and selling the battery, but their claim is there is no money in recycling batteries and all the batteries for sale do seem new. Thus, I don’t know what is going on with the battery! I’m still learning how to balance lead-acid batteries.

I do remember hearing bubling sounds coming from the bad battery. There was not lithium tho. It was lead-acid type and nothing burned up. Now I know it was boiling electrolyte.

The top comes off and you can remove the cells or work on them there. I’ll post some more pics as the plan comes together.

It’s an inconvenience because I have to go back to the inverter and re-start it. And, sometimes it happens on cold-start meaning it’s not nessisary related to heavy cutting load. When functioning good under load the saw is drawing ~700W on a DC circut. It will draw its rated consumption, 1500W, when run on AC.

To be clear about the feature I’m proposing would limit the current and power consumption to 1.5kw without breaking the circut in a way that requires restarting the inverter, or exposing the operator to danger of electrocution or fire. Which is easyer said than done.

I think resistive drop you describe happened to me when I was connecting the inverter to the battery with big allegator clips for jump starting cars. Presently, I’ve got 0ga solid copper wires with crimp on ring terminals on both ends.

My guess is the transformer pictured is at least 100 dollars. Here is something they made that is probably a similar step up transformer.

Cold Cranking Amps (CCA) is the number of amps a battery can deliver at 0°F for 30 seconds while maintaining a voltage of at least 7.2 volts.

For lead acid, you can convert CCA to Ah using the formula Ah = CCA / 7.2. You can also convert Ah to CCA using the formula CCA = 7.2 x Ah

Most storage batteries are measured in amp-hours a 12v 100ah delivers 100a at 12v for 1 hour. And I don’t know how the drop to 7.2v affects the number of amps in a car battery when compared to a storage battery (amp-hour) capacity.

A word of warning: most deep cycle batteries’ amp-hour rating is done at the 20-hour rate. That is, how many amp-hours will it produce at the amp rate that will last for 20 hours. But the total amp-hours depends a lot on how many amps you are drawing.

chart borrowed from: Batteries with different types of power ratings confusing — northernarizona-windandsun

This is for a 12 volt, 100 amp-hour battery. The 20 hour rate is given as 100 amp-hours, which is 5 amps for 20 hours. You can see the amp-hour total dropping as you drain the battery faster. By the time you get to the 2 hour rate, you’re down to 65 amp-hours, or 32.5 amps for 2 hours. Running the chain saw at 1600 watts would take (assuming 90% efficient inverter and probably 11 volts from the battery at that load) something like 160 amps. You’d be lucky to get 15-20 minutes. Granted, the saw would not be running at full power all the time, but the point is, you don’t get the rated amp-hours at higher current.