This is not to say I stopped doing charcoal projects. I have several going right now.

Ok thank you for the explanation

Not really fixed on the FEMA I just like the lidless/opentop design, but it will not be of use if good gas can’t be made from it.

I will use updraft for coal and try to make make a simple fire then.

Hi Jim.

I consider my self a baby in comparition with these Masters that are writting in this site. So I will try to add half cent.

Masters: Please correct me if I am not precise.

- In order to filter tar from wood gas you need to cool it down to room temp witch convertes gas tar into liquid/solid tar ie. water filters, bubble into liquid filters, etc.

- In the topic: “Drawings of charcoal gasifiers for vehicles” you may find some interesting projects.

B.R.

Eddy Ramos.

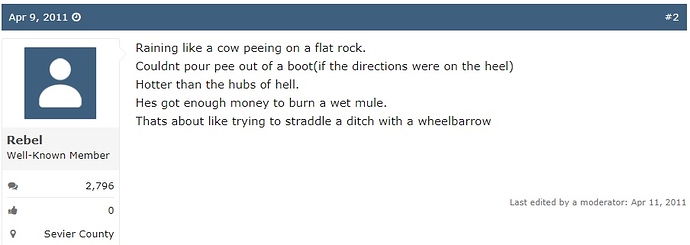

It might be possible to filter tar. Any time I have heard anyone ask Wayne about filtering tar out of gas his answer was “It is about as easy to filter out tar as it is to straddle a ditch with a wheelbarrow”

I like that. From what I hear that about sizes it up.

Some of us are not native English speakers. This idiom means that it is impossible.

I think we have made it clear now that FEMA does not work.

But my next question is, are there any other design with a open top that does work?

That first one about how hard its raining,is one of my favorites! Always elicites a funny look from urban dwellers and polite folks.

Yea I use that one a lot up here lately. The first time I heard it I “shit”. I was too young to laugh. TomC

If it is an open top I would think that would then classify it as a FEMA. Here is the thing , there is simply no way to build a gasifier that simple unless are building Gary’s “simple fire” Other than that be prepared to spend gobbs of money and put lot of time into it. If it could be done all of us manufactures would already be doing it. There have a lot of very smart folks with financial support developing these systems for decades. For small scale systems there are physics involved that need automation stabilize the system for reliability.

Youtube is not doing us any favors with builders showing their builds a few times, with a clogged up grate on a cold start up showing a blue flare. ALL gasifiers are capable of doing this under the right circumstances. Then guys like Mr T showing unfinished builds creating a misconceptions it can be done cheap and easy; then never following up or even finishing his builds. Then what you dont see is these builders following up with any endurance runs under any loading of the same machine and generator. I suspect they fouled the generator or have given up.

Start out with the Imbert gasifier, get the chart, start out with a goal. What size engine are you going to run. Size the gasifier to the engine and build it. Then add on automation and in this day and age Amazon and Ebay sell plenty of electrics that are easy to adapt. Simple timer cycle boards are all that is needed. Once you have flows established and constant even a manual operated air mixer will prove to be reliable to an extent.

Do not waste your time on other methods, start out with the Imbert and learn from here it is a solid proven design.

a good quote to start my day

Sometimes i like “just wandering around” to…

Damn Matt, i envy your creativity…

Yes Jim there is one design of open top that does work for these guy’s , if you start with this link and then follow on to there site they will explain it far better than i ever could .

Dave

I’ve been looking at their site, but it seems it’s been dead for a few years now.

Someone said it only works under constant load and I have not seen anyone use this in a automotive application.

So does this system have a bad turn down ratio?

It seems easier to automate this system then the other woodgas systems.

Hi Jim , i am sure Luk and Paskel are still around and running there systems with good results , as far as an open top for automotive i wouldn’t have thought it would be practical , but what do i know . These guys have worked many hours/ years perfecting there systems with great results for generating power .

Dave

Hi Jim,

I am going to open source a revised and simplified version of my design. This is sort of like Luke and Pascals design except my system has a closed sealed hopper. This is a brand new design and should be simple to replicate. However, my developed design has been pellet fuel specific and a lot people have asked if it can be made to run on chip fuel. This I dont know and have not attempted as I am going to stick to pellet fuel as a standard and can not afford to build chip version just to try out.

However I do think it can be scaled up to any size. This issue maybe that fuel you use may restrict if it is too large. This requires a restriction at the transition from the hopper to the hearth core. At this restriction is a purge vent. The air that purges in at this transition pushes combustion gases down and prevents them from entering into the hopper. If the restriction is too larger then it wont work and you have wet fuel and the design is pointless. The hearth jetting system could not be done any easier as these simply ring flanges that are spaced apart. Any one could build this system with basic tools and some welding. A small version could easily be derived using hole saws to cut the flanges.

I will be featuring this open source design on my forum and will update here as well.

Intresting!

What web adress does you forum have?

Hopefully Ill be in a position this weekend to build the first one.