Keep this thread going, it is interesting how many designs will work while making clean wood fuel , and simplifing designs over time.i may try the ceramic tube on my s10 save weight and use a lighter heat exchanger too recycle the otherwize waiste heat.

Koen wrote:

“one thinks for he does, not following the paved path and teaching us how it can be done ( WK )one does before he thinks, also not following the paved road and also teaching us how it can be done ( Kristijan )”

I used to overthink everything, calculate and theoretizate everything. But l learned a far better way is to just go ahead and do what feels right, it sometimes doesent work, but it is a hell of a lot more fun!

n my case there is wery litle metal-to-hot char contact. The only direct contact is the restriction. The oxidation zone wall and reduction zone wall are insulated with ash/chardust. I allso dont have any measuring devices in the gasifier but l wuld say l reach optimal grate temp within minutes. Offcorse the gasifier is allso tiny compared to what most of you guys are useing

Kristijan, it just doesn’t matter in size or weight if it can handle the heat and can make enough woodgas to run the engine and vehicle at the hi way speeds that you need, and have a good turn down ratio for idling. What more could you ask for? Good job on just going with what feels right, continuous calculating and theorizing with the use of a arm chair builds nothing. Keep up the, “it feels right doing”, it works for you and will work in the long run of Gasification.

I have learned a lot from what you have done, and I know I’m not the only one on DOW. Thank You.

Bob

I think a little extra weight and mass in certain parts of the gasifier severs as a flywheel effect. It may take longer for a cold start up of the morning but will allow the vehicle to set at traffic lights and accelerate with the surrounding traffic.

Confidence is DOW with only 1/8th tank of fuel!

Hi Don, If you are going to a new build “I” have a suggestion. Look at improving the “reduction zone”. The WK design just lets the char fall through the restriction onto the grate which has an outside diameter of some 12-14 inches. Consequently they get fuel size char in the ash pit. Despite my inability to readily understand Max, I believe he has stated the importance of a “designed” reduction. In my case I was also letting the char fall though the restriction onto the grate. Max suggested, a tube below the restriction just slightly bigger than the restriction and insulated on the outside with char ( could be more SC ). I of course haven’t got that done yet but really do believe that confining the char in a tube and forcing the gases through it will take the char down to ash. Then it goes to a grate which Max has a very definite design in mind. TomC

Sounds too easy to plug up to me. I think we have to remember the velocity difference between an Imbert and a WK.

You beat me to it, Don.

I use that setup inspired by Arvid and Max. But as you pointed out velocities differ a lot. Besides you’ll get short on fuel for your popcorn lawn mower

Hi Don, I think there has to be just enough spacing between the tube and grate, to make it work. My grate is at 1" to 3/4" from the bottom of the firetube support plate, and I still slipping a lot of good size char all the time. I would like to see if I could slow the char down and produce more ash, with out losing on performance. I just need to put my brake drum back in and put my choke plate on top of it and try it and see.

I removed it so I would have 12" from the nozzles to the choke plate for reduction. Putting it back in will give me about 9" or so. I moved my nozzles down 3" from the top of the fire tube from the original design. Hopefully this will slow the char flow down a little and burn it up into a little more ash. It’s fun experimenting.

Bob

The lack of velocity is all the more reason to put a reduction tube in. Speed the slow moving gas past the hot char, thus making more crashes of CO2 into C to make more CO. With a pile of char on the grate and plenty of room, the gas is just slowly rolling down the side of the char with no chemical reaction. Or NOT.! Maybe again I misunderstood the theory. TomC

All depends on engine speed and how many nozzles and size of nozzles right?!? In a airtight system this " combustion air" is all that system is going to get! Seems to me that if anything should have a mechanism to regulate it should be incoming combustion air, less at idle, more as the engine demands it!! Herb

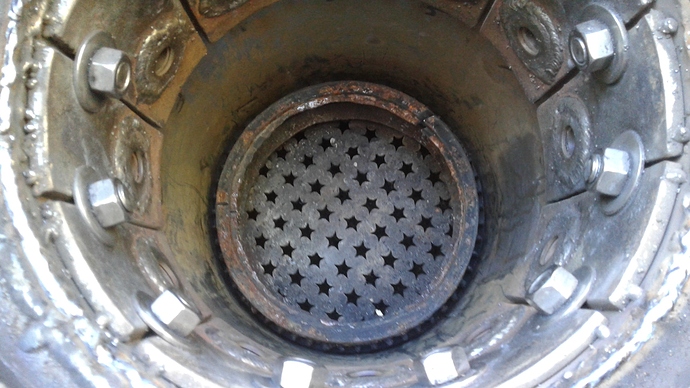

I’ve been looking at Bob’s fire tube above, it has 12ea looks like about 5/8 holes, in my Caddy I had 5ea 1/2inch holes, that is a lot of different for about the same size engine!! Bob’s engine is 318ci, Caddy is 4.9, Bob’s runs fine, the Caddy ran fine, must not make much differents how much Incomming combustion air we give them, do you guys agree??

Hi Herb, the gasifier runs on a vacuum bases, if the engine is at idle then less air is flowing though the nozzles, if the engine is at WOT the flow though the nozzles is greater.

What you can change is the density of the air by adding colder or hotter air. That will change the volume amount. This is what I see in the WK Gasifier, not sure about the Imbert gasifier, or other designs. With winter coming I see the preheated air is going to help at start ups. I do like the Idea of preheating the hopper using the plank method of some sort.

Did your Cadillac have preheat in the hopper area of some sort? Like a double wall?

Bob

Hi tom, I thought it was heat that made the transfer to CO2 into C to make more CO. The speed of the air/CO2/CO is just causing the char to slip and not get used to it’s fullest because of the lack air or O.

Once the gasifier is up to operating temperature at the grate, adding more air or O in will give you more CO, so I’m thinking colder dense air by, bypassing the preheated air from the muffler preheater, when needed. And some how slow the char slipping at the grate by a reduction tube area after, the choke plate so the ash fines can fall though grate and small pieces of char. My char is kicking out to the side of the grate. What I’m trying to do is move the hi voliosity of the gas at this point a little higher up into the firetube by moving the choke plate up and give more area below with a lower voliosity of gas moving in the grate area, slowing the slippage of charcoal down. If it stays on the grate it will hold back the rest of the char above it to be used up in making more CO and methane, and H2. To high of voliosity of gas at the grate will move a lot of char.

Bob

Bob, of course I and everyone else here knows a gasifier runs from vacuum from the engine!! And I also understand and know there will be less combustion air coming though the nozzles at idle then at WOT!!!

What I was pointing out is the volume difference of mine compared to yours and the fact that they both run good, soooo incoming combustion air volume must not make a hell of a lot of difference!! Herb

Bob how much sliped char per 100 miles… My 318 slipps about a gal per 100 miles.

Yes it is the “heat” that makes the transfer of CO2 to CO. The “heat” increases the speed of the gas molecules flying around and “crashing” into each other which knocks a O loose from the CO2 and it is grabbed up by a C. All at high temperature. Adding colder air is probably a good idea. In a regular WK design, the gases come through the choke plate ( restriction ) at a higher rate of speed — that is the purpose of the restriction. ( kind of like running cows through a fence at the gate). After passing through the choke plate, the gases step into a big empty ball room, some 14 inches in diameter and the hight from the choke plate to the grate. All this room allows the gases to slow down as they go towards the grate. The gases can go between the edge of the fire tube and the grate and blow the ash off the edge of the grate. With a reduction tube under the choke plate, the char and the gas are restricted to a much smaller room. Thus forcing the gases to go though the char, as compared to going over/around the char. The confining tube will keep the gases moving at about the speed as going through the choke plate. The result more CO2 crashing into C for more CO production. The reduction tube needs to be insulated because the reduction process takes heat out of the gas and char and if it gets to low, you will just plug up the grate. Proper running temp will cause the charcoal to get smaller until it will fall through the grate as ash.

What you are suggesting about moving the high velocity up higher, and slowing down the gas below the choke plate is probably just the opposite theory from mine. TomC

About a gallon in 40 miles maybe a little more.

Bob

Wow thats a lot of charcoal! And a lot of energy lost! Keep in mind there is a lot of energy lost in the makeing of charcoal, this energy you get back if you burn the charcoal producet but if you slip it trugh you loose quite some efficiancy. Do you return the sliped char in the hopper?

Big gas velocitys are important for 2 reasons. One is to achive a turbolent gas pattetn trugh the whole heart, this turbolence mixes and swils all the gases and solids.

The other is to rip the ash off the surface of char as soon as it apears IN THE WHOLE HEART, from nozzles to grate, never leting it to settle. Imagine a peace of glowing char in a BBQ. The charcoal burns but since there isnt enough air velocity, you just end up with a pile of ash in place of that char. Now, if you blow on it, you blow all the ash stright away. This allso presents a CLEAN, reactive surface.

The grate can now have small openings to alow this high velocity gas/ash suspension to go trugh without ash settling on top of the grate, while the biger char peaces stay in.

In the otherhand, any turbolence is more drag on the system.

Thats why lmbert dimensions are so precise and inportant. A carefull equalibrium between turbolence and drag.

As for chardust, there was a interasting pattent in WW2, called the Käle gasifier, that returned the cyclone soot back in the primary air. Its an interasting prospecrive

I am with Greg.

With my dakota I think I am slipping a gallon or less per 100 miles of char / dust …

Keep in mind slipping doesn’t mean wasting