A lot to break down in that video, several of these I have owned and become very intimate with, and funny how I can spot the video clips taken from several mainline YouTubers videos and well known engine builders. A shame the list is wrong in number one though. I haven’t personally witnessed over a dozen 12 valve Cummins engines break a million miles, 2 that broke 2 million miles, and one that came through the wrecking yard and was bought not dismantled that was over 3 million. The owner dropped it off for a rotted out cab, the junk yard owner bought it and had me put a used cab on it and drove it home gave it to his grandson

All of our engines, in fact, still use the energy of the explosion. But we can also use compression energy.

17 years ago, when I was working as an electronics engineer at the experimental plant of the Scientific Research Institute in Donetsk, the inventor Vladimir Kashcheev came to the office of the deputy director of the plant for science (my good comrade). He said that he had made an engine that burns hydrogen and oxygen, not to expand them, as in conventional engines, but to create a vacuum inside the cylinder. The movement of the piston from the bottom dead center upwards creates atmospheric pressure. One of the problems that he had to solve was the freezing of water vapor on the walls of the cylinder.

Here I found a description of this engine and the inventor’s contacts.

However, at that time Vladimir Kashcheev came by his other invention. He needed to make a mold to produce the second half of his glass jar lid. Apparently, solving the problems of disposable caps for preservation would still feed a person better than a fundamentally new type of internal combustion engine…

Although I may have missed something during this time. And such engines already exist in other parts of the world.

It looks like Porsche has a 6 stroke engine. it has an extra power and exhaust stroke. The ring geat it uses looks like it would be prone to failure, so it just looks like hype but that might just be me.

You may be right, but this will have to be determined in everyday use, over a long period of time, and in many conditions. I have seen too many things succeed that I didn’t think were going to, based on my farm experience. I’m a mechanical engineer. I have worked with pressure vessels and piping systems, foundry, turbo charger development. ‘Truth is stranger than fiction’.

Rindert

Ditto.

Life is stranger then imaginations.

I am just not sure they are going to make it an actual product. It seems like I saw something like this before.

That’s true. When I was a kid, I read every Popular Science magazine I could get my hands on. There were an awful lot of engines, and everything else, that were going to change the world. I think it’s also true that Fiction can be stranger than Truth ![]()

Working at a university, I learned that some folks can’t tell the difference between the two. Or won’t.

LoL. So glad to be out of that. My parents were professors at the University of Vermont. I escaped by working on a dairy farm. Reality is beautiful!

Rindert

It is a matter of approach . . .

A believer is a Believer because belief in something is what gives it credence in their lives and useage.

The other approach is also an extreme . . .

it is not an accepted valid working Truth until it can be math’ed-out, rationalized and explained. So not a Truth; it does not exist to them. Not accounted for.

Until it rears up and whaps’ you in the head. Bites you in the ass. Opps.

A practicalist person just accept things as they are.

On the woo-woo six cycle engine as an internal combustion engine there will be internal combustion blow by gasses. If the internal engine negative pressures are still used as a system vapors capture and burn up recycling them; there will be continuous internal acids building up. Etching and eating away materials.

Connecting rod and/or crankshaft changing variable compression ratio LAB Testing engines work O.K. Low hours of usage with lots of helper maintences.

NOT so ok when in continuous thousands of hours usage as NISSAN is doing now on production general use engines.

Modern Honda trying to create a long life true Atkins cycle internal multi-link engine never could get the rubbing points wear down to their proven hours-in-service life standards.

Many others have trashed their once better engine life’s reputations by adding internal idealizing complexities exposed to harsh internal wearing. Wanting to Believe in better.

Isuzu; GM; VW; Dodge-Ram . . . now Ford.

“Keep It Simple (Stupid)” or KISS - Keep it stupid simple.

Steve Unruh

I did too. And I read a bunch of back issues as well. What I figured out is some of the stuff, they were saying was new, took a long time to hit the mainstream. If it was actually successful, the technology was 5-20+ years ahead of any commercial product.

Most of it is oil is a limited resource. some of it is performance and some of it is environmental, but even the environmental laws are mostly because oil is a limited resource.

I think it was probably in the 70’s that there was an article on one of those popular science/mechanics magazines about a proposed commercially built home power plant using a Fiat engine and using the cooling liquid as a heating source. Ran on the homes natural gas supply. I must have dreamed it because I have tried to find the article on the web to no avail.

You might be nuts but your memory still intact. ![]() I think this is what you saw, and I think it made it into pop sci.

I think this is what you saw, and I think it made it into pop sci.

Thanks for the affirmation Sean. Doesn’t prove my memory is intact. Can’t find the freakin torque wrench I used last week.

It might just mean you need to clean. It is how I have to find stuff if things get too messy because of starting projects and getting interrupted by something else. Too many cycles, I clean until I find it. ![]()

Hey Don Mannes @don_mannes I was searching for an existing engine topic to put this video up on. Tag! Your’s is It:

This video is about delivery oil pressure as it relates to engine wear.

Just did the 2nd oil change on the wife’s acquired 2022 Toyota Highlander Hybrid.

Uses 0W-16 oil.

I am still wrapping my mind around this thin oil.

Some knowlageble references says: Too Damn Thin.

Other saying for this engine application: Just Right.

S.U.

Maybe this is a way to increase fuel economy? Anyway, my major beef with manufacturers has always been that they don’t design in oil pressure gauges.

Rindert

I came across this video today ,its an engine that i for one had never heard of , but after watching this i would imagine they are very rare even in the USA to get hold of , i wonder if any ever got shipped to Australia as i would Love one .

Dave

Interesting, Knight valveless system?

There was cars with these engines, known for smooth running.

Thanks for this Dave.

Nope I never ever heard of this Willy’s lighting plant.

Just Willy’s later auto&trucks sleeve valve engines.

I did read once a late 70’s? early 80’s? build up and running of a sleeve valve engine comparing to the then current developed poppet valve engines.

One of the downsides of the 20’s thru 40’s in production sleeve valve set up was the then oils heat carboning up binding the sleeves movements. Then very hard to start and causing premature wear on the sleeves actuating mechanisms.

Yep. The then, more modern oils did mitigate that.

But then production costs for all of that high precision was deemed too high for any real perceived benefits.

I searched but could not even find any reference to that “hot-rod” project.

I did find other very good modern articles though. The best read was on a Hagerty channel link. Search for it. It showed in-cylinder flow graphics that indicated the flow filling around a poppet valve would better in-cylinder fuel air density layer for better swirl mixing. The proper engineered poppet valve type was better able to get a lean boundary cylinder layer for less HC’s emissions.

All shown sleeve valves were using ~45-60 degree rotating sleeving though. Not up and down as in this engine. I think axial oscillating sleeves were used for higher compression ratios possible for use with modern high octane fuels??

Any brought into production engine has now whole suites of enforced hurdles it must world-wide comply with now.

The in continuous productions, and improvements “conventional” four stroke poppet valve types set standards that any ohh-Wow-neat’o engine would have to immediately jump up to. And even exceed to get the $'s investment moneys to get made, distributed and used.

Regards

Steve unruh

Ha! Ha! I found it. Mike Hewland & John Logan and Keith Duckworth in the Wikipedia article towards the end, under Modern Usage.

S.U.

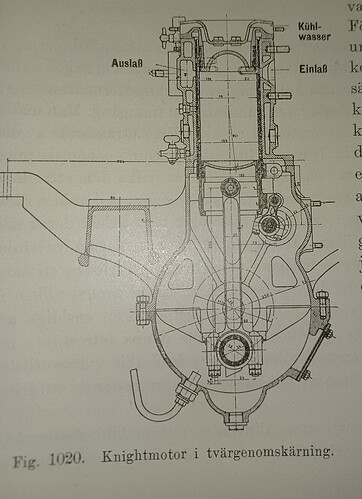

If theres interest, here are some drawings of the Knight “valveless” engine.

From “The book of inventions” 1925.

From “Internal combustion engines, their function, use, and care” 1916.

Observe in the bottom pic, it uses two sparkplugs to compensate for the uneven mixing.

Edit: the Knight engine was invented by American: Knight, it uses double sleeves as could be seen here, both moving.

Thanks Goran, I was wondering how that thing worked.

GC