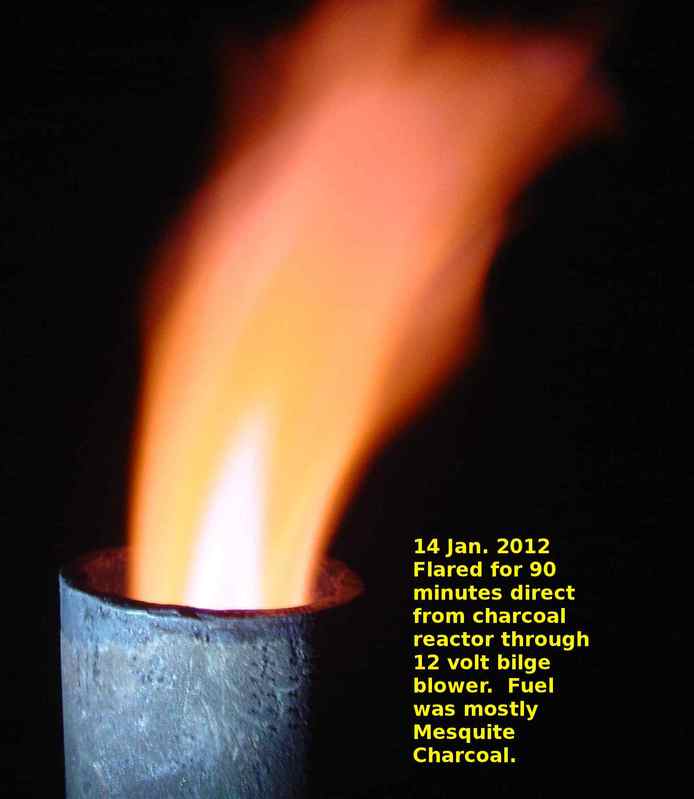

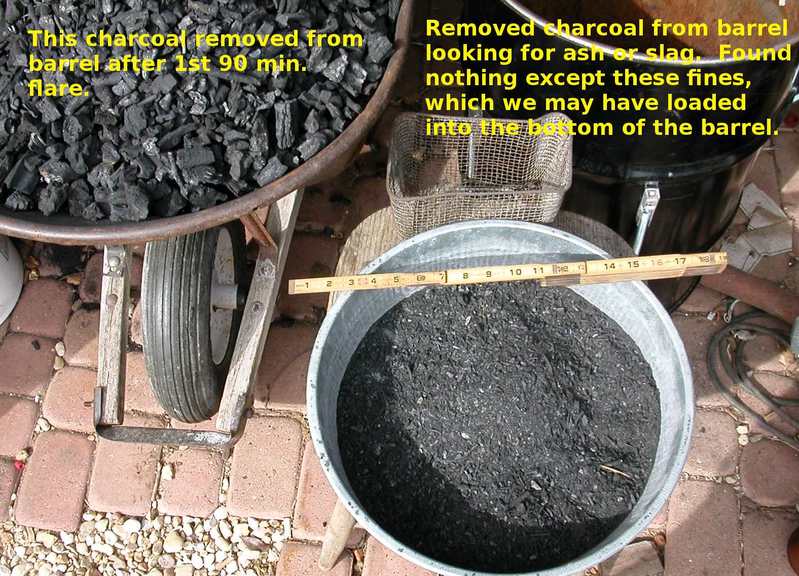

This was the first gasifier, and we flared and flared. Gary’s video showed him dropping dog food, pieces of plastic, oil soaked wood, and all sorts of stuff into the unit, and we did the same. We lit the charcoal with a piece of rope saturated with gunpowder, dropped down the inlet. Our flare was not what we were expecting. It was much too yellow, and we were chasing the “Magic Blue” color. People offered opinions that we were using charcoal made from land that used to be under the ocean (high in Calcium and Salts), or that we had too many dead possums in the charcoal making barrel, or that some sort of other salts were being picked up by our charcoal. In retrospect, the charcoal had way too many large pieces, included too many fines, and may have had even contained raw wood. Later, we stopped flaring, added a GEK Cyclone, and a Gilmore type cyclone with charcoal and foam filtering, but switched the reactor to a Simple-Fire, and got nice blue/purple flares, and were bold enough to run engines. We never ran the output from the Kalle to any engines, thinking it wasn’t good enough.

With the Simple-Fire, we have both EGR and water drip, and the nozzles are protected with castable refractory, including TIG cups, which are copies of the ones Dave in New Zealand had success with. Here is how I made them:

I’m a fanatic about eye and hearing protection. There are safety glass, goggles, and shooting ear muffs all over my shop. I did not protect my skin enough, so I have had 23 surgeries on head, ears, neck, arms, shoulders, and the back to remove skin cancer. (Not a good way to lose weight!) Also, I should have been using sunglasses more than I did.

Now, I suppose I should be more careful about charcoal dust, and probably use those 3M respirator masks longer than I should. Remember those old Western Movies where they used bandannas over their noses and mouth? (Not really effective.)

),

),