Yep. Working DIY gasification runs on Human Determination. That is the secret ingredient.

Regards

tree-farmer Steve unruh

Interesting, i was thinking of makeing a shorter hopper for a raw wood gasifier, then getting a plan for a auger feeder system. sprinkel’ing the wood in just enough for makeing pleanty of fuel, lower wind drag and more distance travel if an auger feed reserve pans out with enough space. Happy argos camping, im hopeing too make it there with a tent this year too.LOTS of camping room and decent shower stalls.

Looking forward to this new build, and the Builder coming to Argos. Also seeing you again Kevin and all the others again that are coming to Argos. Lord Willing. This will be the biggest event yet.

Bob

THANKS bob mac, lord willing as you say. thats the way we all need too think one day at a time.It would be nice too meet the foreners builders for shore allso.

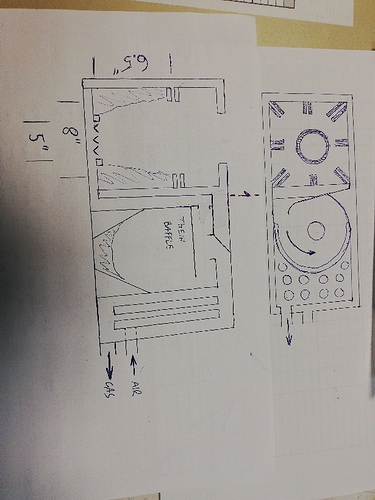

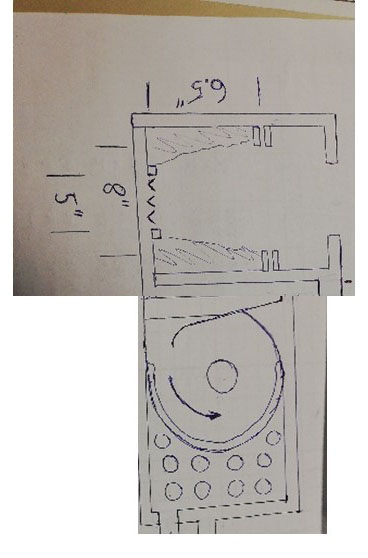

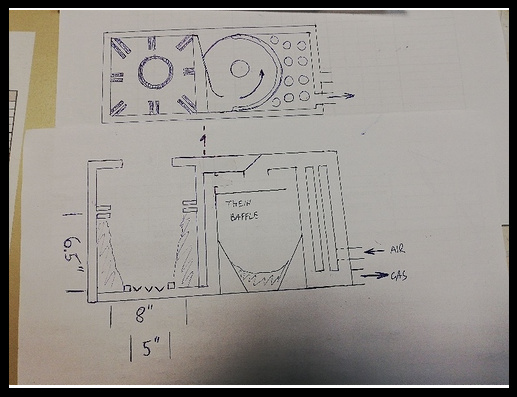

Ok guys here is a crude skiz of what l plan to do. This is the part that will sit in the mufler compartment, without hopper.

The gasifier it self is a cross between a Imbert (high velocity air nozzles), WK (air cooled firetube, “restriction” on the bottom) and a Swedlund char gasifier (insulated firetube, charcoal as main fuel).

The gases flow trugh the grate, then up to a Thein baffle (a less efficiant but more practical version of a cyclone) and then trugh a tubular " cooler/heat exchanger.

Allso, note the transition between the hopper and the gasifier is restricted. I will restrict this as much as possible, to prevent heat escapeing in the hopper while still achiveing good fuel flow.

The whole setup is incased with intake air.

Now, l wuld apreciate opinion from you guys on 2 things.

First the grate. The firetube will most likely not be reachable from the top, meaning there is no practical way of emptying the gasifier periodicly for cleaning as l did on the old system. And frankly, such a messy job is no fun either. Meaning, the grate needs to grind/slip some char/slag in order to keep the hearth charbed clean.

So, what kind of a grate do you guys sugest? I am not a fan of moveable grates but it seems its a inevitable complexity here… allso keep in mind it is wery imoprtant for the grate system to be as thin as possible (height).

Second is the part between the gasifier and the baffle. The gas and ash/char needs to pass up somehow, in the baffle at the top. This transition is the shaft shown on the skiz as -1-. My question is, will the gas be able to push the sliped char and ground slag/ash upward about 8" and in the baffle?

My first impression is I doubt the gas stream can be entirely depended on to clear all debris or possible clinkers. I would plan on having a cleaning auger as Jo did for periodic cleaning.

Hi Kristijan,

this looks like a great compact system. Inspiring for me.

I try to answer your questions from my theoretical point of view.

The grate: I would recommend a moveable grate, this should make cleaning much easier. As you wrote, you can grind some ash accumulations which might otherwise clog the gasifier.

Have you had a look on the grates of the Svedlund and Mako System? They are rotatable, this could be the easiest way. Second suggestion is make it move horizontally perpendicular to the bars to get the best grinding effect. It can be actuated by a rod which can be sealed quite easily. Many old kitchen stoves have a grate like this, just without sealing. This wold not need much building height.

Gas flow to the cyclone: It all depends on the flow velocity, of course. I guess you want to collect everything whats passed the grate (char clinker, shes etc.) in the cyclone? So no need to clean the part below the grate separately?

I would suggest a horizontal cyclone. So the entrance of the cyclone is at the level of the grate. A combination of your two drawings.

A horizontal cyclone is a little bit less effective, but not much. I found a website of one of our DOW members who made some tests about this, but I can’t remember and find the link at the moment.

Anyway, hope this is helpful.

Til

Yes, most helpfull! Our stove has a similar grate, only without that perpendicular arrangement. Its easyer and lower thain a rotating grate. Allso, perhaps just a metal rake on the grate wuld be enough?

Correct. I learned my lessons over the years. With woodgas, use as litle as possible seals, haches, screwcaps, lids etc as possible. Idealy l wuld only use one 2" screwcap as a ash dump and a 4" one for filling lid and thats it. Only with everithing solidly welded you can be reasonably sure everything is sealed well.

Good thinking on the horisontal cyclone! I remember who tested them, just cant remember the name. The question is, will a thein baffle work horisontaly too? I think it shuld. Problem is, a normal cyclone (particle port in the center) might fail as a large diameter cyclone, while a small diameter one will not have enough radius for a useable ashbox. I hope l am even remotely understandable  l need to give it some thod.

l need to give it some thod.

Hi Til,

Thought another view would help. I used a program called “Gadwin PrintScreen”.

It’s free on line, go here: Gadwin - Downloads

Put an icon on your home page, so access is only a click away.

You can capture, resize and reorient pics. I use it a LOT, you will, too.

Oh, what I did was copy your pic off the site, sized it, rotated it and saved it in My Pictures,

and posted it here.

Wow Kristijan; you amaze me how you can plan to put 10# of “stuff” in a 5# sack. So this entire gasifier, minus the hopper is about 9x9x36 inches? Again wow. The only thing I have to say besides, “wow” is— from the nozzle tips to the grate looks like about an 80 degree angle. The general accepted angle for ash/char is 60 degrees. I’m thinking the bottom will spill over onto the grate and you may end up with only about 2 - 3 inches of the grate doing its job. What do you do about a muffler and is there still room for the tail pipe to pass.? Don’t forget the pictures—You know JO likes pictures. TomC

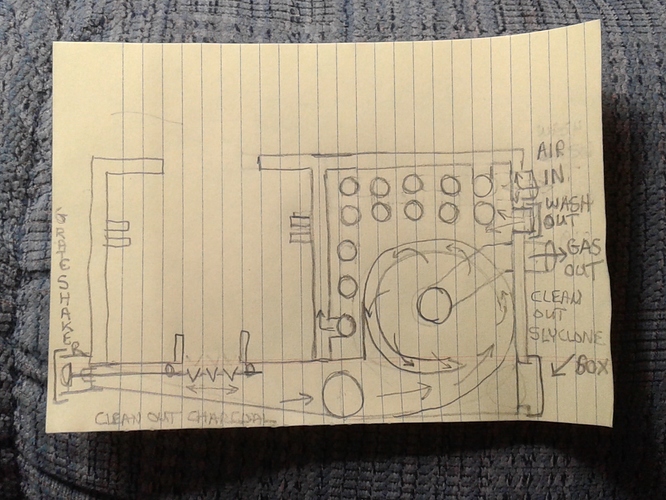

Hi Kristijan, here is a little even more crude skiz, I like your Idea.

With a little slope on the bottom the char will slip moving with the gas direction to the slycone. With a grate shaker I think you can clean that area above it.

The tube heat exchanger needs to be able to be cleaned out, so a clean out at the top of the tubes so you can flush out with water hose. This will clean most of the soot and ash out of tube box and what the slycone picks up.

All cap covers screws in place. There are four of them.

Hope this helps looking forward to this build.

Bob

Pepe, thank you!

Tom, actualy l was allso thinking to put a hot filter in where the heatex pipes are. Have a whole compact system in this shoebox. But l decided to go the simpler way, althugh noting is set yet!

Yes the box is 1x1x2feet.

Oh, the skiz is deceveing, not in proportion. I see what you mean thugh. I havent calculated but l belive the ashslope is not much more thain 60° in rea scale. But l was thinking about installing a cheramic blanket, if l get a peace cheap.

Mufler flyes off. Waits a year at the tractor shed then goes back on for car inspection/registration

It has 2 muflers actualy, and the first stays on. Its quiet enough without the second “main” one.

I was thinking thugh, what l might do, is inforporate a exhaust chanel in the actual gasifier box. It wuld have 3 purposes; add some heat to the primary air, bring the exhaust to the gasifier in case l go with EGR, and mainly, disguise the gesifier box as a actual mufler. Plus l bet the vibration of the exhaust gas will aid to gasifier performance.

Bob, l like the grate under the restriction plane idea! It can be oversized and on a nice track.

Unfortunaly, the slope is not possible here. I can not go a mm lower with the bottom or the gasifier is in dander of hiting something on the road.

Good point on heatex rinsing! I am thinking to install a perforated copper pipe in the gas suply pipe going under the car to the engine, just plug the water on and it shuld rinse it inside out trugh its complete lengh. Perhaps similar culd be done in the heatex? The problem is the gasifier box is only acessible at the bottom…

Yes a pipe on top of the tubes with holes that would spray inside the box would work even better. All the air inlet, gas outlet, clean out for the ash and soot can be on the bottom.

How much space are you thinking about below the grate, 2" , 1" ? 2" would be enough I would think. The car is never flat on the road anyways, it usually sloping to the passenger side because of the crown of the road to remove water from the highway when it rains. I would think the vaccum velocity of the gases would be enough to move ash and char towards the slycone.

In my gasifier when the charcoal bed is getting full, I see char pieces up in my drop box. It is all up hill, 8 inches up to where I have found char from the normal char level.

Bob

Kristijan,

I’ll be straight forward here and just dump whatever comes to my mind.

Your drawing shows about the flow path I’m running every day. Minus the grate.

With a permanent bottom sediment it seems about a 1" void stays open where gas and char can travel. I would like to see a bit more space in the bottom corners though. The flow path will create its own rounded corners and things look a little narrow in your drawing.

Also, since nothing will be reachable from the top, I’m with Garry here. I wouldn’t dare go without at least a 1 1/4" cap on the side, close to the bottom. In case of plugging you could empty with a drillbit/auger.

I vote for an angle iron grate, resting on tabs, movable sideways and with a bottom fixed rod, like Wayne uses, for shaking.

I’m a little hesitant to a horisontal cyclone. It would probably work just fine with fixed rpm and load, like running a generator, but what happens with a lot of variation in flow? I don’t know.

Even if I’ve used only vertical cyclones they haven’t been able to handle big char (>1/2") very good. For some reason they collect ash, soot and small char just fine but quite a lot of the big char settles later on in my condensation tank.

Oh, and in this limited space I think a double walled, heavily finned cyclone would shed even more heat than tubing. Also it’s maintence free, no cleaning needed for heat transfer.

Edit: Obviously I type very slowly. Several posts popped up after I started this one

Bob,

I was thinking no more thain 1" clerence between bottom and grate. The grate doesent let anything bigger thain ~1/2" trugh anyway.

Well l was thinking to keep the pass narrow for gas velocity. But you are right, its a bit narrow…

I belive the problem with big pieces of char in a cyclone is they are too hevy to escape centrifugal force and get pushed down with the internal vortex. They just ratle on the wall till they bounce up in the exit. But a thein baffle works different. It pics solids on the edge rather thain in the center and is exactly the opposite of a cyclone, good for big peaces, bad for fine dust. What l need here.

I just realised there is a mistake on my skech. The cyclone is surraunded with preheat air. But you think its gonna be enough?

If you have room for both tubing and a finned cyclone that’s of course even better. Narrow turbulent high speed air passages would pick up the most heat but then there’s drag.

We have a saying, something like: “No matter what direction you turn your butt is always behind you”

Identical expression here

Well back to the drawing board…

JO, what size cyclone do you use?

5" on the Rabbit. 6" on the Mazda.

Oh, before l forget. I am ordering a A/F sensor. Any recomendations from you guys?

I am old fashioned. I like the analog dial with a slower moving needle that does not bounce back and forth.