Congratulations, it’s really fun the first time an engine runs on gas, good work.

Hi Brian,

Great job!

Btw, I made up a cyclone too, but found that it hardly collects anything. And looking at Koen’s stuff I don’t see any cyclones. I think that updraft arrangement filters out the large particles in the unburned charcoal above the reaction zone.

Rindert

Bryan,

Congratulations. I think you will at least need a foam rubber filter. I, also, have not seen much dust in the cyclone on my 16 gallon drum gasifier. I get right much dust out of the cyclone on the Toyota gasifier, however.

Think about it.

A cyclone only works by flow energy hard spin action.

Low, low small single cylinder flow - near no energy to spin. And start stop pulsating flow to boot.

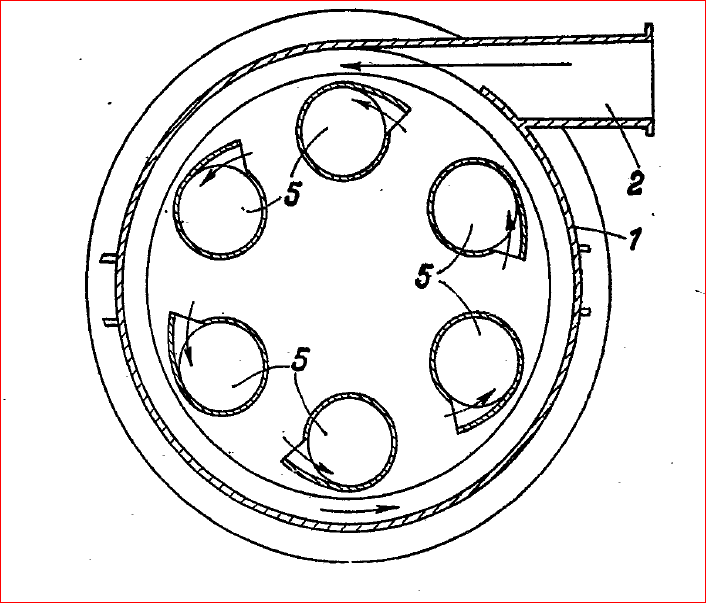

Dutch John DID make cyclones work on his small engines use by using 1/2 " pipe/tubing spinner tubes. Multipe in parallel fo his flow capacity.

Single cylinder engine just use flow speed reduced dropping out flow chambers.

Four cylinder engines then a whole range of options then open up.

S.U.

Good points on the cyclone. Definitely not worth my time for this engine setup. I’ll focus on a simple filter and the cooling rack. Funny thing; I posted my latest videos on Facebook and my uncle (who is a gear-head) basically said “it’s going to be tough lugging that tank around the yard”. I let him know that this is just a test and a more applicable gasifier version/setup would be built if I intended to actually mow the lawn.

Bryan,

You may take a look at my push mower setup in my Toyota Corolla charcoal gasifier project thread at post 100. Mine was intended for demonstration purposes only, but would be practical if it was a self-propelled one like I think yours is.

Yup, if you are actually going to mow the lawn I suggest you look at Gary Gilmore’s Simple Fire. Simple, easy, 5 gallon bucket.

Anyhoo, I’m glad I made my cyclone. On my first run I stupid pulverized my charcoal below 1/8 inch. The cyclone worked. It filled right up with powder. Anymore, I use 1/2 - 3/4 inch charcoal. But since I started doing that the cyclone hasn’t had anything to do. But I’m sure I’ll find a use for it down the road.

Rindert

This was after my first run. See the little pile of powder on the newspaper?

This is a filter I made out of a plastic bucket. It uses four socks as filter material. It gets damp in there. The original idea was to make a water filter, but too much flow resistance.

Steve,

Ironically, I actually shared that photo of your lawnmower with my uncle to show him a better setup for practical use.

Good to see you again Bryan! Nice setup.

What Steve sayd on cyclones. They need to be designed so that the radial velocity is huge. Read: small radius and more in paralell.

On my 109hp 1.6l Chevy l used 2 3" cyclones l think and they worked well even eliminating moisture.

Allso, the thing l didnt know for a long time is that it isnt the centrifugal force that kicks the dust out of the gas in a cyclone but rather the sudden change movement of gas from the outer downward spiral to the upward spin to the outlet. Works like a bull whip, whiping the solids downwards in the container.

If the cyclone isnt properly sized (too big) it works more like a drop box

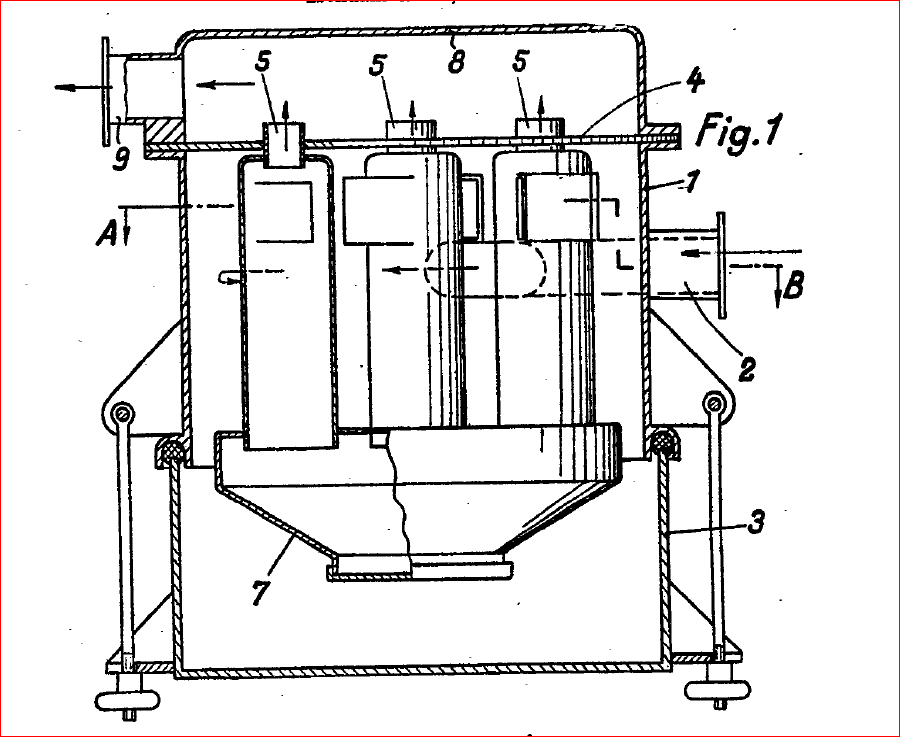

What is important, in a cyclone, is that the first circle be of the largest possible diameter, to have the least possible accenting speed so that the particles are in the ashtray, and then on this model, in the inside the device, multi cyclones to finish the job well

Has anyone tried one of the cyclones with a fan built in like on the original GEK gasifier? That’s the only place I’ve seen one like that. Just wondering.

Hi Kristijan

I installed, on my pickup, two small cyclones in parallel. And for me too, the dust that I collect seems wet and sticks to the wall of the cyclones

do you have a tip for cleaning the inside of cyclones?

Just pour water the inlet in while sucking on them strong.

I ran the lawnmower again for a little over 30 minutes last night . I was planning on having it run until the sump pump hose melted so I could get a better idea of the limits of this gasifier/hose/engine combo. It probably wouldn’t have made it much longer since the end of the hose was getting a little soft by that time. Today I dumped the charcoal to have a look at the nozzle and see if there had been any slag creation/buildup. This was the first time I had checked the nozzle since before I got the lawnmower running on the gasifier. Since the last clean-out, I estimate about 70 minutes of gasifier runtime (20 on the blower flaring gas and 50 minutes on lawnmower runtime). Here is what I found:

The nozzle is still in fantastic shape.

30 minutes of engine runtime equalled about a 3.5 inch drop in the amount of charcoal in the 6 inch tube. This was with the lawnmower running at full throttle, but with no additional load besides the spinning blade.

There was a little slag. Nothing was stuck to the nozzle.

I’m still pretty excited about the nozzle and its durability potential. With this 5HP engine, it seems like this thing could last forever.