Your idea Thierry is interesting and good, but I wonder why you would install a venturi element above, where most of the air is fed directly into the middle tube, and only a small part into the nozzle housing? I would route the entire amount through a heat exchanger, where the air is preheated and carries some of the heat back through the housing.

Hi Tone

it was also my initial idea but this configuration caused me 2 worries.

1: I fear that this narrow and winding passage leads to restriction to the air entering the nozzle

2: I wanted to keep the possibility of being able to suck the air through the exchanger from a venturi in the exhaust ![]()

my gasifier is coal. I believe that the ease of air entry into these gasifiers is even more important than for wood gasifiers. Correct me if I’m wrong

thierry, when you shut off the gasifier, than the cooling air stream stops…will the nozzle resist when stays yet in the glow nest without air cooling?

cooling after shut off with the fan also not works, because in this way the glow nest not cooles down…

we have here only sometimes for some days frost, but i thought how to empty my downslooped nozzle in this case…

i think best is to drain away the water of the tank, and the remaining water in the nozzle protects the thin nozzle metall going in vapour while the glow nest cooles down.

so the nozzle should be protected from excess heat and becomes empty of any water.

when starting again in frost temperatures, refilling again the water system with hot water.

in my side nozzles happens a very good automatic circulation of the water, also the water tank becomes very hot, so during operation would not be freezing danger…in areas with strong frost i could immagine it would make also sense to have the back side of the water tank in the hopper for keeping the water hot.

is this use for a stationary unit?

ps . in a charcoal gasifier i see no problem to cool down the reaction with fresh air entering, it is mostly too hot by itself…so egr use ecc.

too small diameters of the gasifier in this part but creates problems, when there is no insulation

Giorgio, I plan to activate the fan for a moment, when the engine is stopped, and divert the hot air jet from the nozzle. This is why I installed a flexible air injection pipe.

I am modifying the gasifier of my pickup

Hi Thierry,

I like the way you are doing things, solution minded…

a helpfull hint; what way you want the excessive heat at the nozzle tip move towards.

The heat will always move from hot mass to cold mass.

One trick i use is to make the surface / contact area , be it air contact or material contact, linear bigger from the tip of the nozzle towards the outer shell or the source of cold air.

I keep in mind that, in most cases, the ash melting temperature is to be considered as my guideline.

I want to prevent building up slag, as much as i want to prevent melting nozzle tips…

I can’t say that i always succeed… ![]()

thierry, your nozzle with waercooling…not looking at frost problems…have you run the water circuit by gravity or connected with the cars cooling system?

i am always interested in different nozzle systems for charcoal gasifiers…

I’m curious that no one uses castable refractory for a nozzle? Mix up some Satanite into the shape of a nozzle?

My “head” gasifier design has horizontal nozzles with a shelf above so that it wouldn’t bear any weight from the fuel charge. Protected that way, you could use a relatively fragile cast refractory nozzle. It CAN take the heat.

Giorgio this is what my water or oil cooled nozzle looks like (by gravity)

Ps:Giorgio do you live in Italy?

I thought someone tried it but satanite is pretty expensive and it is brittle as you eluded to. Ash itself is a refractory, but I don’t know what you can bind it with to keep it in shape at those temperatures.

I made dozens of 70% alumina cast refractory nozzles in the early days , yes they worked and lasted around 150 odd hours with no water drip or any other type of cooling , but i was always looking for better and came across a piece of Tungsten carbide with a 12mm hole and so i mounted that into a refractory body and that 15 years later is still sat in the shed in 1 piece but the refractory holding it had turned to melted glass sort of mess , that’s when i moved on to easier to find Tungsten variants like Tungsten silica till some one mentioned Hexoly tubes on Ebay for $10 and that first one i still use today and i still have the same one in my gasifier since 2018 it looks a bit worse for wear but is still in one piece and is able to run my large 55gal gasifier .

Dave.

I just checked the Ebay link I have for the hexaloy tubes Dave and it no longer exists. I bought 4 at the time you first mentioned them and the original is still in good shape. Hopefully there are other sources others can access but I’m pretty sure I’m not going to outlive the ones I have.

Hi Anthony,

My experience with cast / refractory or similar nozzles from porcelan or other heat resistant materials have 1 common flow: they don’t like heat shocks…

Any difference in temperature from one end to the other end of the nozzle did lead to breaks.

any quick heat change and they crack.

I like and follow all developments, some i can test, some i can’t… the one i use most at the moment is the cheap fitting as in my “outback” gasifier. It takes the heat away from the nozzle tip, outwards to the metal mantle of the gasifier.

Here some IR pictures from one of the tests.

The welds are intentional thicker to draw the heat to the outer shell

They might just be out of stock for now. They have some little hexoloy tubes on eBay. About 0.40" inner diameter.

The site I purchased from doesn’t exist any longer. What is 0.40. about 7/16?

According to a little app I have on my phone it’s in the ballpark of 13/32".

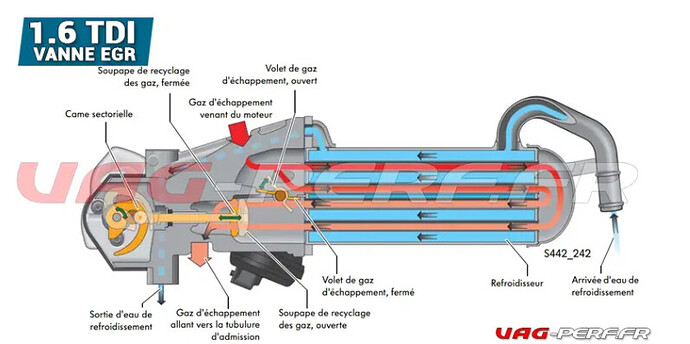

)I’m thinking of using a VW EGR cooler as a nozzle in a gasifier. Air will be circulated through the exhaust pipes and aluminum will be poured into the coolant compartment. What do you think?

Thierry Québec

Given the number of comments my last post inspired (0) ![]() , I conclude that transforming an old EGR intercooler into an “aluminum bath” nozzle is not a very good idea!

, I conclude that transforming an old EGR intercooler into an “aluminum bath” nozzle is not a very good idea! ![]()

I hesitate to try the experience

thierry, the " likes " are mostly not much, comment even less…this comes from a lack of really active members world wide…so the discussions of pro and contra are not so much…best to try out by yourself and share for all readers who are interested world wide…as i myself are always glad to find good informations somewhere in the net, so i try also to show and share my own results to everyone interested, if it is for some active forum members or unknown readers , what are not members…

i am curious about your nozzle solutions, especially of the sight of a frost climate…

the disadvantage i see can be in the problem that a blower for cooling must run for a determined time longer , also when the car is stopped, because of further nozzle cooling in the glowing core

Hi Giorgio , Thank you for your reply

My hypothesis is that a large mass of aluminum divided into many small tubes should provide excellent heat transfer from the outside of the nozzle to the air entering through them. This will preheat the primary air and remove destructive heat from the nozzle tip. As Gorgio points out, the weak point of the system is probably when the firebox is hot and the engine is stopped (i.e., no airflow).

I agree, just build it and have fun test new things out. You might come up with something that will work better than any nozze that has been built before.

I have noticed a lot of active members since my rebuilding of my 92 Dodge Dakota have become inactive for many reasons. Some are no longer with us because of death. Others have built their gasifiers and have moved on to other things in life. Some still active but are not doing any input information now, they might just maybe reading comments. I read and not comment, we all do that.