Why would the roads be covered with trash if they contracted it out? As far as I understand, our recycling materials get baled up and sold off to China by the outfit that has the contract and it’s a profitable business. No trash on the roads.

“DOing makes you humble, healthy and wise.”

Great rant, SU!

“Adapting” based upon outcomes then doing again makes you ever more humble healthy and a tiny bit wiser. Never stop, keep up the great works!

It was profitable. Then the wholesale prices dropped with the price of oil and NG which put a serious crimp on the profits. However, they also got more efficient at collecting, sorting and finding uses for it, so I don’t know if it is still profitable.

It is profitable to ship waste to China because the ship is empty and needs some ballast for the trip home…

Ever wonder about recycled glass in your blue bin?

It makes no sense to scrap bottles and waste all that energy to remelt and reuse it.

They could more cost effectively use it as fill in concrete or for roads but most people would not understand the economics of it or want to be bothered doing the right things ( like cleaning it and returning it to a store for deposit )

Some places claim to recycle over 90% of their waste in Scandinavia.

Truth is they burn it and use the heat, but that is not recycling it.

True recycling means you reduce your footprint and reuse a material and reduce your extraction of the resource from where it came.

We do a good job of this with steel and most metals ( although you have to question a lot of what is put in a can if it could be put in a bottle )

If you want to reduce your waste and recycle more containers used to store food products raise a garden and can your own food. I have glass canning jars here that have been used my entire life and they are still in use. Now that is recycling and reducing the carbon footprint of your dinner.

Glass recycling is interesting. For over 30 years, we have carried them to the recycling bins, but recently I have been smashing them to smithereens in the bottom half of a recycled compressed gas bottle. At first, my intention was to use them as a blasting media in my sand blaster. Then, while mixing up some plaster/pearlite mix, I added several cups of glass “sand” to the batch. Now, I am wondering what will happen if I add some to some castable refractory? I know I can add it to portland cement. Some people in New Mexico are manufacturing a product called “Growstones”. http://www.growstone.com/technology/manufacturing-process/

They mix the ground glass with a bubbling agent (carbon) and fire it in a kiln where it foams up. (The same process that must happen in a nozzle zone of a charcoal gasifier?) Afterwards, it is smashed and graded and sold to nurserys.

http://www.growstone.com/about/products/

I have even asked my neighbor to save her glass bottles for me. My main source (at home) of bottles is those that were used for Hot Sauce, so it takes a while to get enough to smash.

I think adding glass to refractory will act as a flux, the glass is designed for low melting point. Foamed brick material might be interesting, but hard to control the process on a home scale. Brick clay will make a green glassy foam if heated enough. I’ve wondered what would result if it was crushed and melted again.

Out of all this talk about recycling, this is the only one that bares reading and comment. All the other suggestion require time labor and energy and you end up with one of the cheapest products on earth — sand. In order to use glass in cement, asphalt, or even fill, it has to be ground to the consistence of sand. We tried driving a bulldozer over piles of glass to crush it down and putting it in asphalt, or even fill for roads. It was problematical where ever we tried to put it.TomC

I don’t think it is quite sand. It has air holes in it that retain water and let in air, and the particle size looks bigger. It is at all the hydroponic stores around here so they are probably paying quite a bit for it.

Their process reminds me of like boiling sugar for candy, if you get it too hot it foams up, and they want the foam.  I wonder how hard it is to make…

I wonder how hard it is to make…

As a kid I tried putting a glass bottle into a cement mixer with gravel to break it up for cement before hand. It didn’t really work that well and my uncle got a big kick our of me having to dump the mess out and pick out the big bits… then I used a hammer to finish them and decided recycling one glass bottle for full was more then enough. After that nails and broken bottle just went to the dump not into cement.

When I lived in Florida 25 years ago the recycling center we sold our beer cans to paid a penny a pound for clear glass and 2 cents a pound for green or brown glass. I never seen this anywhere else since.

The used to resmelt the glass. Since they switch most bottles to plastic, and cut down on how much glass they were using. I don’t know if they even still resmelt it. Some places still collect it, but it is just the opposite clear glass is worth more and most places won’t take colored glass at all.

Here they just sort out glass in one bin for recycling all colors and clear mixed. I am pretty sure it is crushed and used for road bed fill. They do that some with tires to.

I notice a lot less glass in use these days. I probably put maybe 1 glass container in the recycle bin every other week, that’s it.

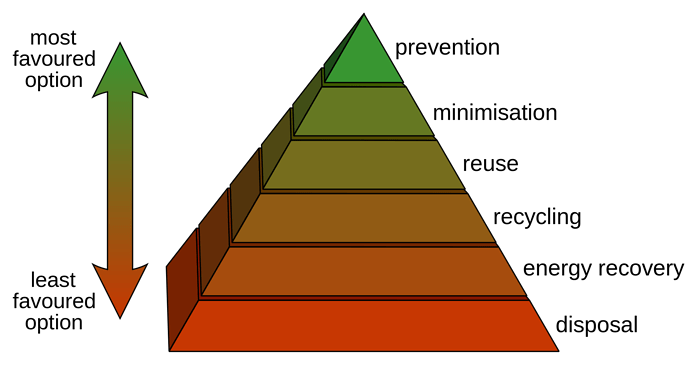

environment starts here…

put yourself at the top of this piramide, then think about the work you need to do

in that perspective you’l find that being lazy with wasting is best…

http://www.pv-tech.org/news/2016-was-us-solars-biggest-year-to-date-with-record-breaking-95-growth

Interesting how much of that is utility scale solar installed last year in the United States.

I knew we were going to install more and there were steady increases. I didn’t realize the total would be a 95% increase.

China installed like 2.5x as much. They are also pushing for 800k electric vehicles being sold this year which is like a 50% increase.

I am kind of waiting to see what Tesla’s solar shingles will end up costing. I know a -lot- of people don’t like the looks of solar panels, and they don’t like the fact you still need a roof shingles.

The Tesla roof is thin film and it only has the life span of the shingles. It will not come close to panels for performance. I wanted the thin film you roll on the roof but it is way more then the Canadian solar panals. So I guess I will buy from our neighbors to the north who may have made them on NA or in China there is no way of knowing as they manufacturer in both places. Hard to complete with 65 cents a watt I think it is.

Thin film usually degrades faster then silicon, so you probably only get about 20 maybe 30 years out of it anyway, which is about the time you replace your roof. The silicon ones degrade but they can go for decades. they just drop in performance so in 50 years they might only be kicking out 50-60% of their rated power.

I didn’t know Canadian Solar actually made anything in the US. I thought they just imported everything from China via canada to get around the tariffs. 65c/w was the price from alte. I would probably ask about just buying pallet loads of them. Then you creep into the lower price ranges. typically it is around 20-22 panels per pallet. The utility grade sizes are usually cheaper, but they are bigger panels so maybe there are fewer per pallet.

Well I would ask about bigger that is less install as I see it. Yes a pallet will save some. I thin the north American plant is actually in Canada but I could be wrong just read somewhere that in Austria all Canadian solar panals come from China because they sell all they can make in North America on Canada and the USA