Looking good Chris ,you are coming right along with it .Those uniseals look to work really well .

Thanks guys. Don, the backwards saw idea wasn’t mine either, but it works great. I’m leaving off the cap for now, I plan to use the blower stack instead. If I want it I will just order another smaller uniseal and pop it in that way.

Bill, I bought these barrels here, 2x:

http://www.newpig.com/pig/US/nut-bolt-ring-open-head-colored-poly-drum-drm772

They were $46 each, the uniseals were $3 each, and the plastic welding kit was $165. (If you find a better price on any of these let me know.)

So far I’m convinced this is the way to go for a hay filter. Haven’t seen any downsides yet… will keep y’all posted.

Looks good Chris. The only thing I would like to suggest is to not use a street 90. Instead go with the solvent weld and glue a small piece of PVC to slip into the barrel. I say this because a street 90 may allow itself to want to continue to pull itself in further with time an vibration under constant suction. A female solvent weld hub will at least keep it from that possibility. Otherwise it’s a great idea. My 2 cents.

Pic of ABS with solvent welds

Good point Bill, but where will it go? It can’t change angle of attack because of the rest of the pipe. At that angle it can only get so far then stop. What I may do for testing purposes is mark the depth and see if it ever creeps.

I’m not sure if it comes through in the videos, but that rubber really grips hard. I’m not concerned with anything falling out!

Looking good Chris.

The plastic barrels should be good for the long haul.

Without having any experience driving with a unit on my truck, I’m not sure how things may move around. The point is, a regular 90° elbow will have a built in stopper, so if something does give or wiggle loose, it can only go so far. A street 90 won’t be perfectly round except right where a hub will be able to glue on.

Partway through installing. This is a bigger job than I anticipated, since I’m rerouting the gas lines as well as adding blowers. Quick video showing progress end of day:

Thanks for the video Chris. I am watching this closely so when it comes to do mine soon I will know just how to do it. Do those uniseals allow you to take apart and re-install?

“Do those uniseals allow you to take apart and re-install?”

That would depend on your arm muscles… Yes they do come apart but not easily. Reinstalling is slightly easier than the initial insertion. Heat gun is very handy for softening the rubber.

I just want to comment that as I was working on the pop valve on the red truck, I found almost all of the white PVC fittings to be distorted. As I just use duct tape to hold them together I just put them back the same way they came apart. I’m not sure if it was engine heat or if they are just a bit fluid. Just keep an eye out. What is 2" round today may be 2.25 by 1.75 next year … Mike

If you are having trouble because of temperatures, try CPVC.

http://www.harvel.com/piping-systems/gf-harvel-cpvc-industrial-pipe

" bigger job than I anticipated " Ha, always is for me, but you are making a good job of it. I like the “exhaust pipe” look on top, can’t wait to see that flare.

Back to it. I’m working on my blower switches, using a few basic electronic bits to build a flip flop circuit, operated from bed or cab by push button.

Diagram here, “Relay Toggle Circuit Using a 556 Timer” Circuits Page 9

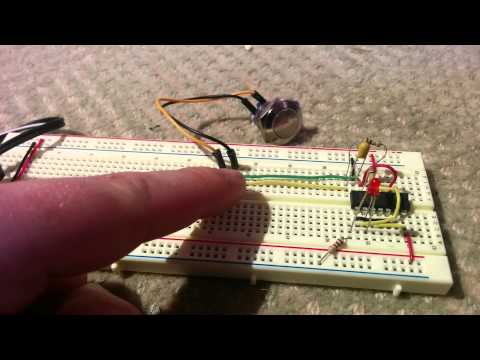

Couple videos of the circuit in progress:

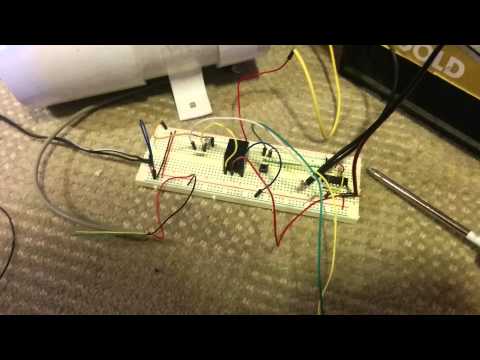

And the first circuit soldered onto a strip board:

Seen the video this AM. Because I’m not much into electronics and can’t see past just having a switch for the blower. Do you mind explaining why the relay and transistor are important?

The transistor can handle far more power than the chip outputs, and the relay can handle more than the transistor. It’s like power steering for electronics. Another way to think of it, Chip > Transistor > Relay works something like Brains > Nerves > Muscles.

The circuit as a whole is just a nice-to-have. There’s two switch locations, that’s the problem. How will you wire two to both work? Currently they’re in series, which works OK. You have to have both of them on, meaning you’ll need to turn on the cab set before the bed ones will work, or vice-versa. Currently my startup routine begins with pre-loading all the switches and valves in the cab, then climbing in the back.

The advantage to this setup is that it’s always ready to go. It’s a small thing but it will make startups a bit easier. I wanted to put the blowers on a relay anyhow, to take the stress off the switch wiring (pulling full power through a little switch is a bad idea). Together with a relocated tennis ball valve control, I’ll never need to open the drivers door until it’s time to drive off.

Hay filter made its maiden voyage today. I have a friend (Dr. Mike Bomford) who has a farm with plenty of junk hay to spare. I drove down there on dino juice, filled the new hay filter and returned on wood. No problems, I need to test for air leaks but everything is running fine.

Blowers are installed but not wired yet. Same for ball valve. It’s so nice that this gasifier design can run (well!) with many of the peripherals not even hooked up!!

var dmdEmbeds = dmdEmbeds || [], btAfnb_w=‘425’, btAfnb_h=‘327’;

(function(){ dmdEmbeds.push(‘btAfnb’);})();

Good to hear Chris!

good to hear you were running on wood again… gotta like that a bunch

Can we say: versatile, ingenious, crafty, adaptable, can-do, never-say-never.

A long hiatus for you, I’m in withdrawal myself.

The add ons included you Chris, and I think Wayne in the past getting by without the fresh air heat exchanger hooked up temporarily. This speaks for the core design being effective without the extras polishing off the whole. Where else is there an automotive product where you can go down the road with part of it?