Do you still intend to heat the hopper with exhaust gases and install a probe (hygrometer) in the exhaust gas cooling radiator?

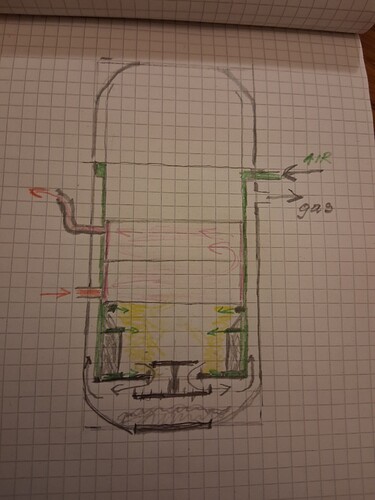

Thierry, as you can see, the inner narrow boiler has an additional heating jacket already made, I plan to use this for heating with engine exhaust gases, well, a hydrometer is not in the plan, since the purpose here is to gasify wood, where “too little” moisture is not a problem,… ![]()

This will be very interesting to follow Tone, on how you will handle the extra heat in the lower part of the hopper cone restriction area with hot air being added from nozzles just above the main firetube nozzles are located.

Okay… but excessive humidity is a problem. If the probe detects moisture in the gas, couldn’t it activate mechanisms to reduce the humidity upstream? Like cooling the lid or a vacuum in the condensate drain (like Kolyvan)…

Thierry, I agree with you, maybe I’ll install a moisture meter, well, my calculations or predictions show that the ideal cooled condensation zone is with a temperature of 70-80 °C, so there remains a suitable amount of water vapor to “cool” the hot zone…

Today there was not much progress, I cleaned the inside of the containers and prepared a piece of sheet metal for the partition in the hollow part for heating with exhaust gases,…

tone, i see in a few days a new gasifier is ready…i need month…

the weights of the forklift…is it full iron or hollow and filled?

Giorgio, this gasifier will not be finished so soon,…

The forklift’s load capacity is 1500 kg, the weight of the forklift itself without weights is approximately 1200 kg - 1300 kg, the movable weight consists of 4 pieces of solid iron (approximately 400 kg), a full gas cylinder (120 kg), a lower support plate (150 kg),… total weight approximately 2000 kg

Let’s move on from the forklift to our main activity - the manufacture of the gasifier,…

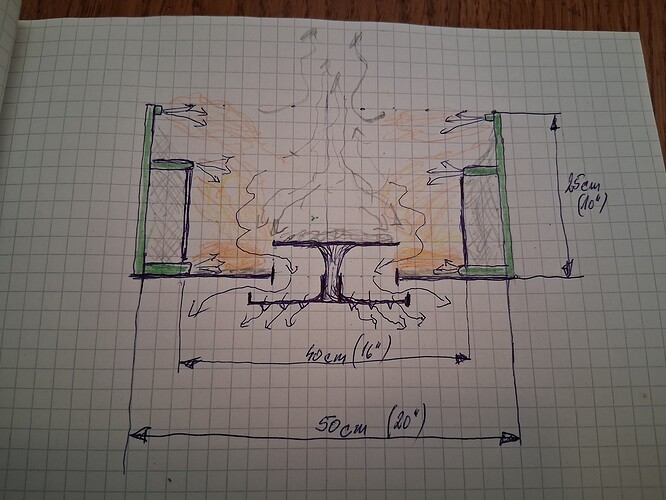

The partition in the jacket for heating the funnel is welded, the plan is to continue the hot zone with the same diameter of 50 cm, which is a very large cross-section, well, I have another piece of the same diameter with a double wall available. I will use a piece with a height of 25 cm and make holes at the bottom for the exit of gas and ash, the picture shows how I plan to do this.

This thing will be a real wood burner, the bottom nozzle will play a key role in preventing the passage of tar gases, I also rely on the heat of the exhaust gases, which will “trigger” pyrolysis and push the moist gases under the hood.

Your trademark Tone and you proved it does a great job. Looking forward to this build.

Really like the cardboard mock up Tone. Makes the drawing much clearer. ![]()

No central nozzle Tone? All the air from the outside?

Joep, I haven’t decided yet how I’m going to make this most important part of the gasifier… I’ll definitely keep these dimensions of the wide and shallow hot zone. There are three levels of air nozzles here, so the gasifier’s capacity will be variable, fuel jamming and bridging will not be possible. The lower level of nozzles will perform a similar function to the middle nozzle, the only difference will be that the gas flow will be inward to the center, which is better from a temperature point of view, and the ash will also be deposited downwards. The production will be simpler, although not very simple. For the supply of fresh air, I will make another envelope made of thin sheet metal, which will surround the storage tank and the hot zone, so the air preheating will be very effective, and there will be a barrier for the condensation zone and a thermal shield between the hot exhaust gases and the resulting wood gas, which will cool on the outer wall,…

Tone, I love this design; it seems much simpler to achieve with external nozzles and especially without the complex heat exchanger grid. Don’t you think the fresh primary air could cool the condenser lid before being heated further down in the gasifier?

Hi Tone, if you don’t mine some input, how about run the two water lines down through the top of the cold air inlet spacer. Then your inner part of the gasifier unit can be lowered into place and make a seal at the bottom of the air intake spacer seal ring. The air can go both ways around the air housing to each nozzles. Much easier to make a seal in the hopper area through the wall with less heat to deal with. This will also heat the water a little more with the longer distance of the piping. This is unless you need to come in at these points for the water to flow properly and not get to hot. You could insulate the piping going in and out.

Looks like a nice 4’ tall and 24" wide gasifier. I really like the wider and shorter firetube area.

No need for a shaker or grate. Instead a top plate to hold the charcoal up in place. I like it, the lower nozzles burn up the fines and move ashes that are building up and then they are moved down and out by the nozzle force of gases moving out to the bottom into the ash and char dust area for clean out.

Less then 6 " at the bottom. Are the lower nozzles going to be air control able, if you have a hard vaccum pull on the gasifier?

Hi Tone, I love your out of the box thinking on things, but I would be concerned about the restriction/bottom plate getting very hot from the lower nozzles that are blowing along its side, warping it and soon enough burning through.

I bet you have thought of this and It feels like I am missing something or simply not understanding fully (which isn’t far fetched ![]() ).

).

Friends, thanks for the comments, …

the lower nozzles will supply air close to the floor plate, we must be aware that the area here is filled with ash and fine charcoal, 10 cm of the path from the nozzle to the outlet is enough to consume all the oxygen, I notice this with the “Fergie” gasifier with a middle nozzle. The temperature load on the floor plate will be quite high, well, I expect that a layer of ash will quickly accumulate, which will protect the metal from high temperatures, I will also choose a more temperature-resistant metal. Below I plan to reinforce the floor plate with “fins”, which will also be a heat exchanger for redistributing the temperature and also for additional heating of the fresh air.

Through which level of nozzles will the fresh air enter? The answer is simple, through those that are closer to the outlet, where the negative pressure is greatest, … The cross-section of the lower nozzles will be 4mm (8 pcs), the middle 5mm (10 pcs) and the upper 5mm (15 pcs).

This build starts at 875. I wish it could be separated from there into a separate build thread.

Good idea Tom, once again very interesting and without a doubt a big succes. Do you ever fail Tone?

The members of this forum are very friendly and considerate, so there is no fear that a comment will disappoint me or “throw me off the track”, I am happy about all the different opinions. Maybe Chris will move these contributions to a new topic, well, here too the topic fits the title.