Ray,

Now l need to know more about your fancy pizza oven. Culd you describe it a bit more? And we do like pictures

Kristijan,

Since living for some time in Germany and buying bread made in real wood-fired ovens, I’ve wanted to build an outdoor oven to go with all my other outdoor kitchen stoves. My wife bought me the Uuni3 for my birthday, and the package included two bags of special food grade wood pellets. ($25 for 22 pounds!) https://uuni.net/

When the pizza stone reaches 932 F according to a dual laser thermometer, the pizza is placed in the oven and is done in 60 seconds. This is for a thin crust Neapolitan type Pizza. She also bought me the cast-iron sizzler pan for steaks and vegetables. Sometimes, after we make pizza, and there is still quite a bit of heat on the stone, I make some flat breads, with a bit of that wood fired char taste.

Getting back to Senne’s flame photo, my first thought was that he may have had a grate similar to the one in the pellet burner for the Uuni3, where a very large flame is actually desired.

There is a large Facebook group covering Uuni modifications, and another one dealing with recipes and results (Pizza). I believe this last photo of the two flares came from a posting on the FB group, and I can’t give proper credit. There is a new version called the Uuni Pro which has options for pellets, wood, charcoal, or propane as the fuel. It is more expensive.

I’ve watched the uuni from its humble beginnings and a rather clunky prototype. It is now a pretty sleek appliance that is available at Walmart and Amazon.

Me too i really wanted to get a UUni and started saving my money to get one , but then saw a advert 2 for the price of 1 on the "kool grill " and being a charcoal man decided that was the toy for me , let me tell you its the coolest adjustable fan forced charcoal grill and so far no problems after a years use .

Dave

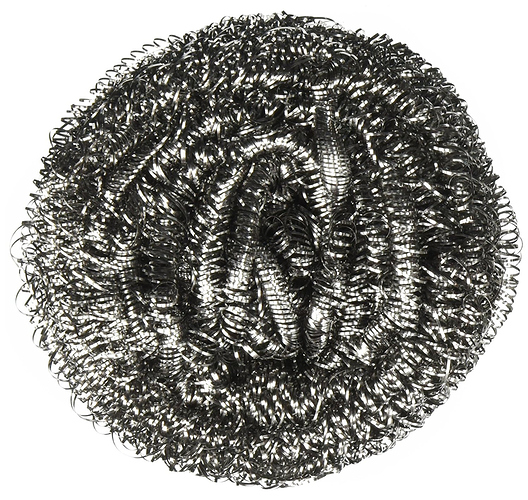

Nice! It seems a bit large but it might do the job as a filter. I would put either a ss or copper chore girl (dish/pot scrubber) in the input and output to stop any flame front coming back from the engine or test burner. No one seems to address this issue except with springs on the gasifier lid. Simple flame arrester.  Oops pardon me…Chore Boy not girl (times have changed) They also come in SS but you might have to find them.

Oops pardon me…Chore Boy not girl (times have changed) They also come in SS but you might have to find them.

Sorry about the size they are only about 3 to 4 inches in diameter. I wanted to give you an idea as they would pass the gases and still provide backfire prevention by reducing the flame front temperature .

This is what I did for my mini WK. There are different qualities of these SS scrubbers. Some reason some of them rust. I think people had problems with some that came from China.

Finally some charring and flaring progress!

TLUD stove produces close to 2kg (4,4lbs) of charred woodpellets (pine) after sifting.

A look into the nozzle with blower on full speed.

Flare with no filter

Gasifier after first flare test. Reaction zone might be a touch to high?

I will try to run a riding mower that I was allowed to practice on as a test engine. It’s a 12hp B&S. I had to do some work on it in order to get the starting system ready but it works now.

Got most of the parts for building the filter and carburator so updates will hopefully come soon!

-Senne

Well done Senne, I bet you cant wait to get the engine running now , hope to see more very soon .

Looks like a very neat build and with a vertical nozzle in the bottom ? . tell us more please

Dave

Thanks Dave, can’t wait indeed!

The nozzle is a vertical one. 1/2 inch thick walled stainless steel.

I feel that it might be on the narrow side for running a 12hp engine (I was first planning to run a small generator). But using Koen’s spreadsheet it looks fine in theory. We’ll see how it goes.

-Senne

I’ll never throw another old blade away!

Where do I get these DOW stickers!!!

First test succesfully completed today on the riding mower!

A few issues:

- flare was not able to sustain itself

- high temperature on the pvc coupling (hopper was filled 20%)

- dropping hot char between switching from blower to engine

Still I am very happy that I could get it running this fast. I will post a video soon.

-Senne

Hi Senne , well done again ,and cant wait to see the video .

On the non sustaining flare , that could be a number of reasons so if possible show us your flaring off pipe , it may be you need more air holes around to keep the flame going , or sometimes a air leak in the fan or pipe work has caused that symptom for me when not getting a constant flare .

20% hopper filled is not enough to cool down the gas you will need to start off at 100% full and keep an eye on your temps once you know what the max temp will be before meltdown of your pipework and thats the refill point for you

Dropping hot char out the bottom when switching from fan to engine isnt a big issue but just be safe and keep a tin with water under the air inlet pipe so that any hot char will fall into the water tin and not land on the floor and starting a fire . Dave

Thanks Dave for your reply.

I think the flare issue is because of the leakiness of the fan. The resistance of the filter medium is enough for the fan to start pulling too much air trough the leaks I think. Because when I first did flare testing without an engine and without filter medium it went well. It was the same flare pipe.

I will try another run with a full hopper when I have the char!

We intentionally teach the extra holes in the grate so the TLUD can be used as a cookstove and not a chrcoal retort. We teach it as a refugee camp stove.

…edit…Sorry, one of these days I’ll learn to read the whole thread before I respond.

Cool looking machine Senne.

Senne,

Great work and workmanship! If you look at the flare photo, it looks like the flame is burning a bit inside the pipe, so there is air coming in somewhere. There may be air leaking into the housing of the fan, like you said. The filter would then make it worse.

Slowing down the fan motor might help when flaring.

Got it flaring on low fan speed and some tape, but it’s not yet fully fixed.

My new inner tubes for the front wheels arrived today together with a fuel shut-off valve so I can switch easily between charcoal and gasoline.

I did also change the carburator connection. Looks like it is holding up better at the moment. I will post close-ups soon.

Next week I’ll start fitting the reactor on the back end of the mower.

-Senne

Don Mannes; Step in here and tell Senne what can happen when mounting the reactor behind the driver’s seat. TomC

Congratulations Senne.

I saw the smile from the first hit of the motor