A specialist is someone who knows more and more about less and less until they everything about nothing.

This college graduate with some graduate school studies, due to personal interest, did fun and self-help projects before, during and ever since college. Being cheap, frugal and stingy helps, too. Each individual and situation is unique.

Yes Steve Bowman, true. But exceptional.

My blood family; and my neighbors the rule is the more advanced education; the more degrees; the less they do for themselves. Oh yeah, they will “games” galore. Fun, fun recreate. Talk, talk. Debate, debate. Damn near everything.

But not grow carrots and potatoes. Not grow meats. Not do any plumbing. Not do any electrical.

Oil changes?! “That is what Jiffy Lube does for me.” “AAA will change my flats. Jump start me. Bring me some gasoline.”

I apologize not for saying this. Direct from family get-togethers.

Too many Union Tradesmen are just as bad so far as doing as little as possible for themselves.

“Steve, help me fix my lawn mower.”. A working mechanical engineer. “Steve help me figure out how to restring my weed eater.” A three degreed fellow with an I.Q far higher than mine.

Again; true occurrences just this summer. Twice on the different re-loading auto string heads. I do not even use these. I use a solid aluminum spool head with 18" pre-cuts that I make up. No dried saps clogging bound up plastics for me ever again.

Mech-ca-nick me I did figure theirs out. Without breaking them and silicone spray washed, cleaned and lubricated. Gave away my own spray cans. Telling them to after finshing ALAWYS spray it down until dripping. Shake off. Knock on wood.

So goes Life. Take as much as possible control over your own.

Steve Unruh

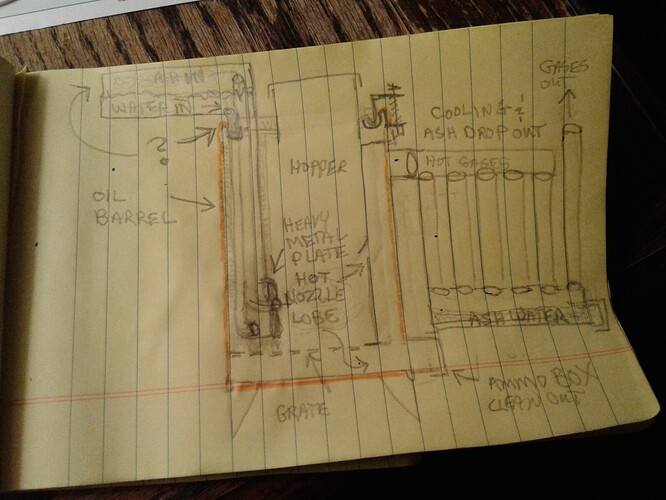

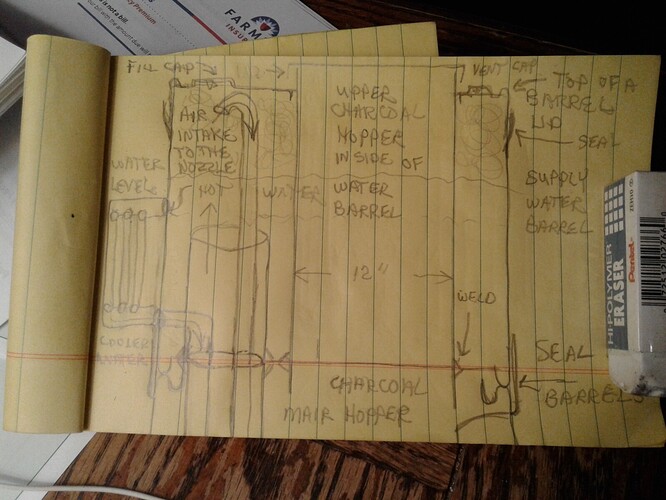

I thought of redoing the gasifer design from the original, so I will use the same topic title. The hopper will have a straight vertical wall.

The nozzle will be water cooled and the waste heat will create moist hot air to enter the nozzle for more hydrogen production. The fact is I will not be using anything from the old design. Lol, this is because I have learned so much more great infomation from the DOW members since it was first constructed.

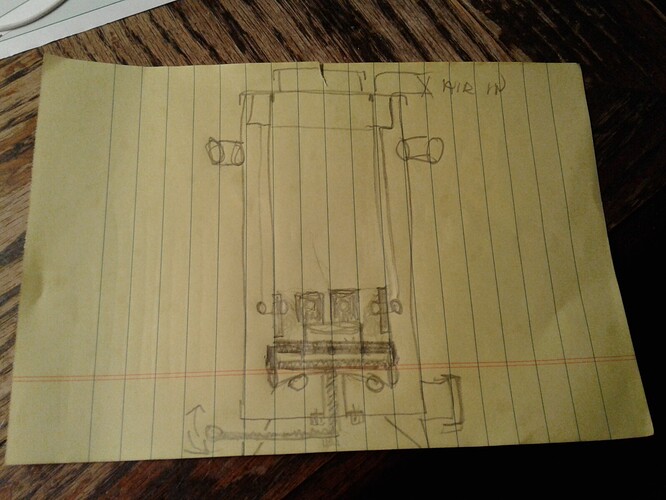

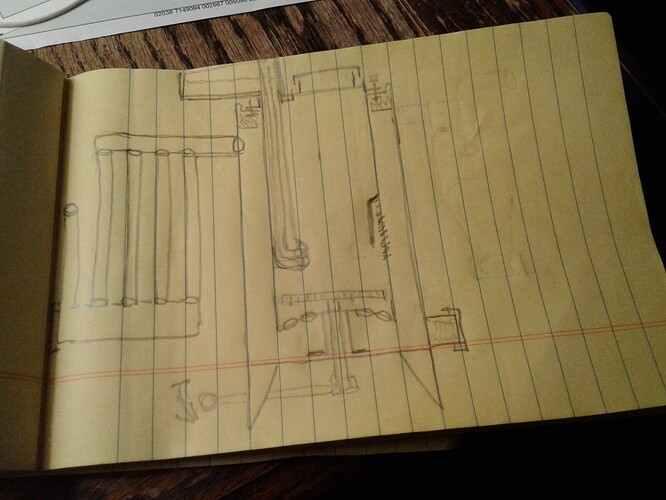

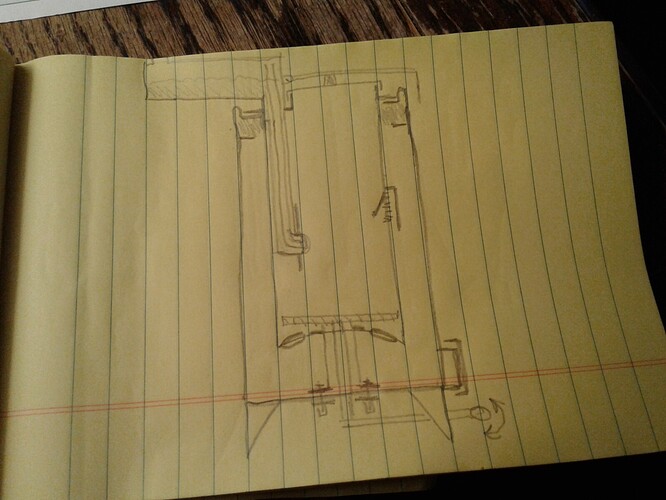

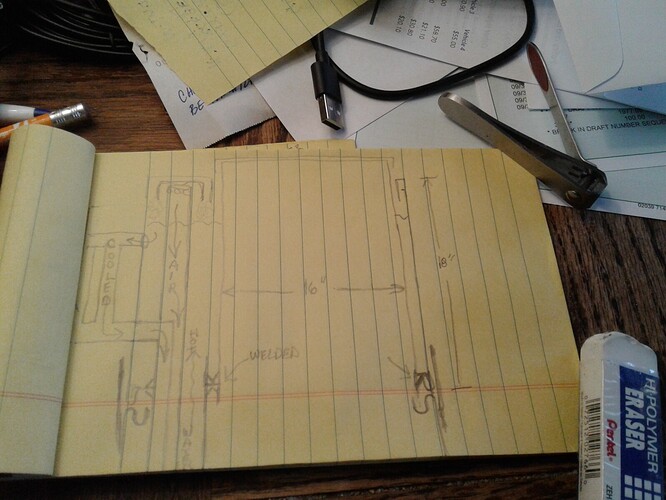

This is a few draws I have thought about. The last drawing I really like the nozzle and water tank are one unit. But the tank is just not right sticking out off to the side. Then I saw it in my mide, a water tank barrel on top of a gasifier barrel with the upper hopper built into it and it is all one unit. With waste heat from the hopper heating the water too. The 5" pipe is filled with water the cooler water goes to the bottom of the 5" pipe and the intake air pipe goes down the 5 " and is welded to the thick nozzle plate with one hole for a nozzle. I like Tone’s idea with a big grate for gases to go through and a higher wall grate for gases to also go through. All most everything is built inside the main gasifier barrel to give it a more stealthy design if used in a small truck. It will be mainly used for my genset like the original gasifier.

Here is a picture of just the upper part of the gasifier and water tank and upper hopper.

I will make a better drawing but this is what I saw in my mind at the time. I did not want it to vanish like a dream in the morning when waking up and not remembering the complete dream.

With a added water cooler tubs and feeding it down its own pipe to the bottom it should start a cycling effect with the hot water rising and cooler water dropping. The air intake pipe will be at the top of the tank drawing in air as needed. The hopper lid will be a pop off relief if needed.

The three first drawings are more complex with mechanical moving parts for operation. Trying to (Keep It Super Simple). KISS this hard for me to do.

Just rethinking everything. If I make a rectangle channel instead of around pipe for my water passage to the nozzle, I can get more space on the side of the upper water barrel. With water cooling tubes on the side and the surface area of the tank it will help keep the water from evaporating away and help keep the nozzle cool with the water exchange pipe at the bottom. I can also insulate the water return pipe going back down from the heat in the gasifier area. This will also give a larger diameter for my upper hopper and more charcoal loading storeage to burn in a hopper load. Trying to Keep It Super Simple. KISS. DOC. Drive on Charcoal.

Sure is easier to draw it out on paper than build it and then try to make changes. I think I got it Right! We will see.

I like the water jacket around the charcoal hopper. One thing about my gasifier that bothers me now is how the hopper heats up during a long run. A water jacket would help cure that.

Another thing about my gasifier that bothers me is how the gas outlet temperature also rises over time. I wonder if a water jacket would help cure that. I haven’t run into issues yet on the engine side, but that is only with a couple hours of run time. I worry that with a very long run time as the charcoal gets used up, the temps will reach a point where it does become detrimental. I can see the fuel gas becoming less dense and causing engine power drop off or other problems. I have been thinking about a water cooled heat exchanger instead of the air cooled heat exchanger I have now.

The only problem with gasifier getting to hot is metal melt down. When fuel gets low in the hopper radiant heat becomes a problem with seals and metal. Keeping hopper full in these areas will help. Charcoal is great for insulation. Ashes is too.