Hey Tom how do you run that kirby backwards?

DonM often times the continuous flame lighters in starting up gasses stacks are to burn off visible stinky smokes for public acceptance of woodgasing.

APL/Jim Mason in the Cal. Berkley/SF Bay airshed region later-on shows using continuous propane flames to clean burn starting gasses and keep complaint until the system could be fully all through an IC engine combustion/cleaned.

A way to make no-visible smoke that can be complained about.

S.U.

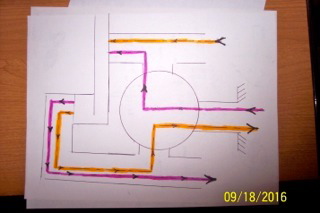

Don: Here is a rather bad drawing of how I reverse the flow from my Kirby. Along with the picture you will get the idea. It is all based on a three-way valve.

I have since hung it on the front wall of the bed of the truck so that it doesn’t take up as much floor space. I don’t have a recent picture but if you don’t understand how I hung it let me know and I get one ( it will be reduced so it doesn’t take so many picels) TomC

Hi, Tom!

13.9.2018

Your blowing of air into the ashpit, to blow air upward trough whole the charbed,

also fills all the coolertubes and pipes, and filterbarrel toward the motor with AIR!

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::

Then by a long sucking you are seemingly getting back

“new gas” through the cooler and the lower part? of your filter barrel.

( No cyclone or settling before the cooler?)

The upper part of the filter keeps “fresh air” a long time, as it is not (seemingly) blown through by anything else than backward leaking fresh air from the motor!

To get an effective starting on gas, you have to rationalise

the whole flow pattern!

As it seems now, it gives a full reason for very long startings.

Hi, Tom!

14.9.2018

I don’t intend to lecture about what can readily be found in the library books,

but from the gasifier outwards, a first coarse hot, dry cleaning stage

with a “daily emptying” pot

will spare a lot of brute work along the rest of the system.

Hi,Tom!

14.9.2018

When reorganising the system flows, the startup dirty gas should be blown out as straight as possible; passing no more components than necessary = the cyclone for safety reasons.

Pushing fresh air direct to the nozzles gives the choise to blow upward or downward for obvious needs.

A “fireing up” box can be attatched in front of the nozzle-entrance for using spirit, white spirit, kerosene, etc to start up the fire. Or buthane, propane. Initially with “soft air-blowing”.

Also an electrical glow-plug can be used; making the starting procedure completly hands-off and weather independent.

The glow plug is then placed at the fringe of the char abowe or below the restriction.

Good morning Max ( or evening which ever the case is for you. ); Well I am ready for a fresh start. I have burned up all the old wood. I did through in some new wood to try to get it going but then the battery went dead on the truck starter.

Ok the plan will be to start from ground zero. I have plenty of charcoal left over from the fire. It got hosed down but has had several months to dry out. Clear out everything even if some is left in the reduction zone ( will try dropping the grate to empty it. Wouldn’t it have been nice if I had made an ash door where I could work with the grate better:thinking:) Then fill up to a little over the nozzles with fresh charcoal, then throw in some fresh wood chunks.

Now another mistake I made was not “clocking” the fire tube , nozzles with the air manifold inlet. So the best way to ignite the gasifier is poke a whole through the new chunks and light the char from the top. WK style.

With my set-up, I am thinking you are saying to blow downward from the nozzles, I should pull a vacuum on the ash pit ( grate, reduction zone, through the nozzles ) and close the hopper lid. Then to blow upward I should put pressure on the ash pit and open the hopper lid to blow straight up or should I leave the hopper lid closed so I blow back through the nozzles?

No glow plug for now. Need to work with what I have. It ran a couple of times as it is so I should be able to get it going again.

I need to cut some chunks before I can try again. The weather is beautiful for drying some chunks but my wife says it is also beautiful for me to mow the lawn. Guess the wood truck will be put on the back burner for today.

Thanks for you persistent help. TomC

Hi, Tom!

14.9.2018

My description of today started from “a clean table” ; as if done with a new

lay-out system. With blower pushing clean air only !

Mess. 847 !!!

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::

Okay, as it is existing today you still have to pull the dirty gas throughout all those places…

I hope the “bottom char” is dried up and tar-free enough!

Hard to out-live the grass!

HI, Tom!

16.9.2018

Never pull or blow gases backwards trough the nozzles!

That is really destroying the heat tranferring properties of the preheating mantel!

Good thing you said that. I interpreted something you said to think blowing through the nozzles was a good thing. I will tape the opening to the air manifold off and blow and pull with the lid open so the air goes up and down through the entire hopper of wood , how ever full it may be.

Having trouble typing today. I ran my thumb through the table saw blade while chunking wood for the gasifier. Carl Zinn chunks his wood with saw and it works for him, but I think the saw blade glazes the surface so that it is hard to dry afterwards. I am using cut offs from the construction of my shop, so they should be fairly dry, but the lumber companies over here dry the wood just enough so when you take the last swat on the nail to seat it good, that water doesn’t squirt out from under the hammer. I can’t wait to get back to reworking my wood chunker but no since having a wood chunker if I can’t get the truck running on wood. Hopefully, I will work on the truck this afternoon. Want to drop the grate and clean it totally out. I have plenty of good charcoal to put back in there from the fire. "till I have something to report. TomC

Hi, Tom!

16.9.2018

Blowing outwards / sucking inwards, should be selfevident!

Until your system is renewed, you cannot perform blowing in the sence I have meant. Out from the nozzles.

I will keep my both thumbs up so you get good desinfection stuff and a good “plastering” around your hurt thumb!

If the teeth on the saw-blade are enough schregged, the cut surface will not be polished blank.

When filling after emptying, fill-up charcoal 4 - 5" abowe the nozzles, because a new bed is fast settling.

Be careful!

I thought all guys our age typed with one finger.

When I was a junior in high school we had some really cute girls taking typing.  TomC The rest of the guys in my class took “wood working”.

TomC The rest of the guys in my class took “wood working”.

I am not so old… i can type with 2 fingers… but not on my phone, then 1 only…

Aha, so you were the type of guy, taking typing for that type of reason.

(couldn’t help it - late nightshift humor).

That type-ically describes me

The original ‘cause’ that effects everything. LOL

Hi, Tom!

18.9.2018

Have you finished the lawn moving while the weather was good?

1. Fill the emptied hearth with ONLY char till 4"

above the nozzles.

2. Remove the air-inlet tapes!

3. While Kirby-succing, light the char ONLY in the center,

on the surface.

4. After 5 minutes, with closed lid, look if the fire has been

creeping out to the nozzle-tips!

5. If the fire has been "taking root" at the nozzles, and

whole the upper surface is eavenly glowing, add 2--3"

of wood.

IF NOT, 5 minutes more with closed lid. Don't stir!

If the wood is well and eavenly lit (with lid shut) after 10 minutes, add more wood.

This under constant Kirby-succing from below.

If the gas comes out clear, light it! Then drive…

While ligting the wood, in the beginning, protect youself for possible “blurps”!

This is observation prosedure, not correction procedure!

Thank you Max. That seems very clear to me. I have put wood on top of the char already, but fear not, I will remove it to get back to the char. I have spent too much time on this subject already to do any of it incorrectly.

Hopefully later today I will have a report for you on yesterdays activities. Right now I want to get back to taking the wood out of the hopper and getting to the char. TomC

Ok Max; Success at last!

I decided yesterday to clean the hopper fire tube and what ever. I started out the hopper looked like this;

When I was making all the latest modification some wise person said to make the grate so that you can removed it. I had never had a situation where I wanted to remove the grate before but I half listened. I made the grate so that I could release in and let it fall into the ash pit. I didn’t cut the bottom of the gasifier so that I could take the grate out however, which I was also advised is a good idea. Anyway I got everything cleaned out down to the restriction. Then I opened the ash door and used a small screw driver to poke through the bottom of the grate and try to agitate the char so that it would fall through. That didn’t work. Something was keeping the screw driver form moving. Well, I had made the grate so that I could drop it down-- so that is what I did. When I got it down the following pictures were what I found hiding on the grate;

Huston, I think we have a problem!

I cleaned everything all out. Then started rebuild the char bed per Max’s direction.

This is the “fuel sized” charcoal that I filled the fire tube to about 4 in. above the nozzles.

This was the layer of char over the nozzles.

I lit the charcoal and closed the lid and let the Kirby pull on the hopper from the ash pit for about 5 min. The char directly above the fire tube was a solid red glow. The I kind of deviated from the instructions. I have a pile of charred wood left over from my fire that had not been ground down to fuel size. Shown in this picture

This is some good char and it’s size resembles what I usually find between the raw wood in the hopper and the small char below the nozzles. I dumped the char over the glowing char in the bottom of the hopper, opened the lid and close off the air inlet to the nozzle manifold. I turned the Kirby around and blew up from the ash pit, out the lid. When I could see the glowing embers coming up to the top of the last char thrown in, I put a buck of the chunked wood I had cut and dried into the hopper…

I let the Kirby pull on the hopper with the hopper lid closed and nozzles open for about 5 min. Then I adjusted everything and started the engine on petro. It ran just for a few seconds and died. I shut the gas off and started the truck on wood gas. After a couple of minutes, I got out and put two more bucket of wood in the hopper and put two bag of wood in the back of the truck and took off down the road. I drove for about 35-40 mile ( no speedometer) Going down hill I would shift in to OD and if the road was flat, it would hold the speed. The slightest incline and I down shifted out of OD. The slightest up hill and I started down shifting through the gears. Very happy with that part. I did have problems when I slowed down and went around a corner. When I down shifted and tried to pick up speed, it was very sluggish and stuttered. Now I just have to saw up some more wood-- and get a bag of lemons. TomC