Hi Kevin. Sorry I haven’t gotten back to you. See my post 935, the 3rd and 4th pictures. The lid clamp is wide to assist stability and the bolt has a “snug” fit ( not tight ) in both the clamp and the hinge stand. TomC

Ah, Good morning again. Yes, I believe I understand that the hinge and latch points have to be moved up or down to raise or lower the imaginary feather bow line and any reaction to such a move is in respect to the hopper/lid seal plane. ( although my movement in this drawing is in respect to the physical lid and not the hopper/lid plane as it should. but look back at post 965 first portion.)

Interesting that your comment to Bob was that when the feather bow is correctly below the hopper/lid plane it is “pulling” down rather than pushing.

See my previous post to Kevin, to see that I do have respect for broadside hinge restriction. TomC

That sounds like about what i built on top of my barrel for a lid holder spring clamp, Wayne may have the best yet design, though its hard too keep any lid from lea king a little after a meadium too larger burp, due too the simple fact of small char dust getting caught in a ll lid designs, as the lid trys too pop back in place it has char particles in between the lid and the seal. Maybe the Questain or project should be what design deflects the char particles durring burping the best. Just a non engineering persons idea thought.Happy designing,Fun. kEY WORDS. flitter flatter shatter burp sneese fart flash.?? Wood gasifier hopper door seal. Heaven.?? ///

Hi, Tom!

13.10.2018

Important observation!

The main lid is correctly pulling down the filling lid against

its seat with help of the feather-bow!

The feather-bow-ends are not anchored “in an imaginary space”!

Good morning to you Tom, and all the others in this discussion. Tom, here is a couple pictures of the set up that Chris S. built. I only modified the latching part with a old ski binding release system because Chris electric fence spring was not strong enough to help with the sealing of the larger lid he built.

The spring on top is for alignment of the lid only. It does not touch the lid when closed.

I too was getting smoke out from under my lid on shut down, cleaned it per what Max suggested.

My feather bow , hinge, and latch hook are above my sealing part of the lid. Also my ski binding latching system is not inline with the bow. The lid is attached to the under side of the bow with a nut and bolt, and has a lot of movement side to side play in it. The bow has bend in it acting like a spring, but the ski binding is spring loaded too and will release if there is a big explosion. My lid only puffs a little like you explained.

It works is the importance of what I am getting at. When I had vacuum on it , it sealed even though it leaked a little with positive pressure.

Different design from what Max is describing I think. But it works.

Bob

Good afternoon mr. Bob Mac, that doulble springs or springs on the edges seems it would keep a good seal . I just think maybe the rim on the bottom may help allso. I was thinking maybe a double deep bottom rim as the barrels might help as well. Maybe extended wedge affect bottom rim narrow in the center and wider on each side of the rim not as far portruded as the center section.?? the lid might need a guild too make it not move past the rim alinement.?? just a idea maybe.

Hi, Kevin!

15.10.2018

Draw it!

Hi Kevin, one good thing about my seal edge no char can get stuck into it if it puff, it does have a tendency to want to stick at cool down, so I have to keep it oiled.

Bob

Hi max,I aint got no brains on drawing, what i was thinking might be a little much fab work. Just thinking a deeper seal area, possible with out the reg rope seal type, if the lid was square it might work easyer. though for the rim side i was thinking like two wood chizels back too back about 1 " long for the rim shape. And maybe two rope seals for the slot too make the seal. probbly too much time invested too build for testing.

Hi Tom, that sounds like the inspection hatch door I made for my drop box, it is square and smaller. Only 6"×7". It never leaks at all.

Bob

Sounds good! If one can find a lath with a square profile with one side “almost missing”, at a scrap dealer, and get a circle- bending mashine making a “rim”, welded to the lid…

Then finding a square or rectangular profile silicone foam-rubber

~50% larger than the rolled square-U-profile… to stay in the profile.

The silicone foam-rubber list has to have the contact-surface with a “skin surface” in order to not glue against the filling opening edge.

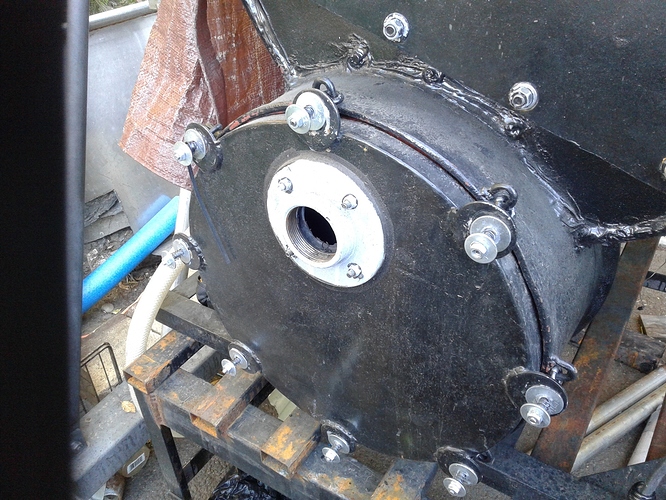

Hi Tom, I open up my side clean out, inspection hatches on my Charcoal gasifier and the WK gasifier this morning to give you a idea look of what you were talking about. The round side lid hatch is spring loaded and can puff off if need in case of back fire, has not happen yet. It is 16" in diameter. The square one is 6"×7" it has a bolt bar locking on it. They both have stove rope impregnated with red silicon sealant.

If I was making a hopper lid I would build it with the seal in the lid. They do not leak at all.

The round hatch lid is exposed to 300f and the square hatch lid is exposed to 500f. You notice the heat shield ceramic insulation on the square hatch lid. Hope this helps out.

Bob

hi max, true i wish i had the machine shop skills and tools, back too the drawing board for now. Ya that might have worked good that way. Like whos got that much time these days, about the time we think were set, something will change too cause time too run short.?

Hi, Kevin!

18.10.2018

If you do not have the material to “compose” an own roller, go to a neighbor who has one! With a bit of luck a neighbor can give a tip who has a roller… if not having himself…

Good luck!

Hey Kevin on this top-stuff let me help maybe with a cut-and-fit approach.

The woosh-poof pushes UPWARD. IF the lid/hatch system type allows twisting, or one side favors movement, then be much more difficult to evenly SELF-reseat.

You want the lid retainer to PULLED back down evenly around to reseal.

The WK sytmes poofs-release/reseating as Wayne builds them is many spaced around evenly pulling springs. This works excellent for that one purpose. He separated out the actually filling lid to a separate exprenced-skilled-hand-operation. See his working video’s.

What max and Tom have been discussing is a one-lid does ALL system. And Max with many seen earlier evolved tool-less easy-use European working systems in his experiences base.

So to begin . . .think of a man under an old style parachute. Gravity pulling the man down BELOW the evenly distributed out by many cords domed parachute “pulling” upwards. (yeah, I’ll get slammed for this one!)

Turn these forces around reversed and this is what Max wants in a good fill-lid/poof combination system.

Now with a single spring bow/feather controlled lid you are much more like a modern rectangular directional parachute. The basic lay out of the pivot and latching ends; the width/stiffness and attachment(s) to the actual lid WILL be your parachutists control.

Done right best-practices and then a fellow should be able too fuel chunk bucket/basket edge bump unlatched&lid opened. Dump-in fill. Bucket/basket edge lid flip back down& bumped relatched.

Look Ma! No hands touched. No muss.

Sure. Sure. Most will want to soft bagged fuel refill. Two hands needed and no hard edge to be your lid tools.

It’s O.K. No elegant designing and fabricating needed then.

Put on your gloves then (ha! I do) and hands-on: unlatch/unbolt, flip up/removed lid, bag dump-fill, wipe seating, flip-closed/pick up and pop lid cover back on, thump to seat, rebolt/relatch closed.

All just depends on what you want and how much effort AT WHAT POINT you are willing to put into it. ( meaning . . . A Designer/designs . . . an Operator will make any design workable . . . and bitch just how hard the Designer has made him work to make it workable)

Regards

tree-farmer Steve unruh

Steve; I take one point of this post.

In this group “we” are the designer, builder, and operator. So we have no room to bitch— just go sit in a corner and think up solutions— or go to DOW for suggestions.

Hi steve thanks for the reminders, more gloves, less ingineering dreams, Like you say wk malti spring lid seems too work without insident Good enough. Parts that are allready too reperpos is my best bet any way. Back too the grind stone , i got too get my hot water heating wood gasifier done before getting time too remount a vehicle gasifier again.

Some parts are easier to understand then others… Tom, i think its meant to be "solving your own design is less complicated then solving a problem the designer, who has no clue what the operator has to endure, created "

In some cases, as per your own design, efforts, sweat and tears included, simplicity prevails…

Thinking in functionality is one keyword i try to implement…

In case of your cover: many designs try to include multi-functionality… try to forget about that…

You want 2 functions, filling lid and puffing lid…

Solution:

1: make one lid that can be closed tight, the easy way, no springs…

2: on that lid, or another place, make an overpressure valve that never will be opened unless you have a “puff”

On stationary designs they use aluminium foil rupture disks, but i am sure a larger tennis ball will work to

A larger , heavy rubber ball, 4" size, on top of a 4" pipe as a blow off valve maybe ?

I could think about hundred different idea’s, some will work for me, some will not work for you…

I learn from any builders experiences, oh my Budha, thank you for the DOW forum and its members…

i think this one fits all… Hands on mentality… sometimes i forgot the gloves and burned my fingers, sometimes i wear flipflops and do plasma cutting…

On DOW i learn from my mistakes and others successes… and vice versa… but mostly i learn from the positive critics i receive…

Damn, writing this i can’t stop dreaming of paying a visit ( study trip ) to each build talked about here on DOW… wow what a trip that would be…

Thank you Koen; Right off hand I can think of one person who thought like you are saying with a “separate” puff exhaust. That was Don Mannes design. Your comment makes it so simple that I wonder why I have been flogging the same dead horse all these years, trying to make a lid seal and yet let lose under pressure

One of those "hundred LIKE " post TomC

H&H welding in Mason, mi, I believe they have a large roller and do custom work. The people who sell the sheet metal for furnace installs also have one, and a large brake, and will do it for you, but they only do sheet metal thicknesses. otherwise, you can make a roller, there are online video’s and directions for it if you poke around.