Hey all, well for the first time we are ahead of the game. We are getting the 2016 models ready for pre release this year. Next year we are going to revert back to just two versions of the M-Series the (M-Series I and M-Series II). Next years M-1 will be based on what is now currently the M-II with the 8" hearth and the 2016 M-2 will be based on the current M-IV with a 12" hearth. We are very pleased with this years M-IV’s performance; so not much is changing for the gasifier / reactor portion. The big changes for next years M-Series is the filtration. We have come up with an easy to service system that will allow the full cleaning with minimal disassembly. The filter tank now integrates the complete filtration into one unit, but is still modular in its design. So replacement parts will be simple, easy and inexpensive to replace. This will also allow us to offer different materials for certain portions of the filtering system later down the road. I am going to build an aluminum condensor core later on to experiment with. This will be a thick wall aluminum tube condenser, even if we went with 1/8 wall tubes this would still be more effective than 16 ga mild steel. Aluminum has a unique property that makes it dissipate heat faster than it can absorb it. But that will be an experiment for a later day  The cyclone is gone for next year, instead a two stage filter will take its place and should prolong the dreaded full cleaning services. There is a simple coarse filter placed before the main filtration with a bin for emptying coarse ash debris and then a finer filter is placed at the top of the condenser to catch anything the first filter misses. We are going to explore different non combustible filter medias for this. Insulation and lava rocks are the first things we are going to try. In addition the wheeled chassis kit will be standard again and new for next year will be the automated grate and hopper agitators also standard equipment. The arduino mixer may also find its way as standard equipment along with other advanced automation we are working on as well. We will need to develop the O2 mixer with the narrow band sensors and then I think it will be cost effective enough for us to be able to offer it at minimal cost added.

The cyclone is gone for next year, instead a two stage filter will take its place and should prolong the dreaded full cleaning services. There is a simple coarse filter placed before the main filtration with a bin for emptying coarse ash debris and then a finer filter is placed at the top of the condenser to catch anything the first filter misses. We are going to explore different non combustible filter medias for this. Insulation and lava rocks are the first things we are going to try. In addition the wheeled chassis kit will be standard again and new for next year will be the automated grate and hopper agitators also standard equipment. The arduino mixer may also find its way as standard equipment along with other advanced automation we are working on as well. We will need to develop the O2 mixer with the narrow band sensors and then I think it will be cost effective enough for us to be able to offer it at minimal cost added.

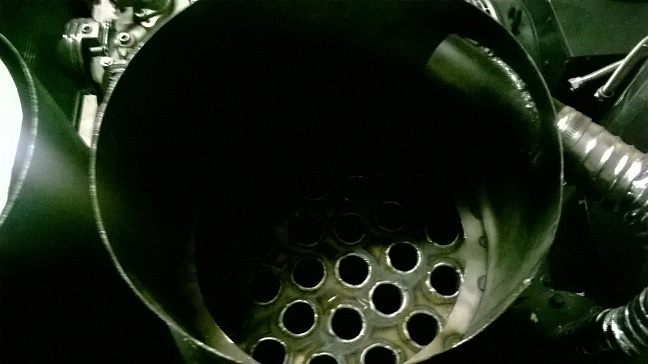

In the pics you will see our grate reduction design. This is a simpler two stage reduction system that is similar to the ES versions. The grate is not fully vented and you can see we have a sill placed in the reduction skirt. Above this is the first stage down draft reduction. Along the side ash builds up here creating a natural insulation, along with other theory. The lower portion the gas is then pulled in a cross flow direction. Rather than going straight down and packing the gas and char is pulled to the sides loosening the char bed while maximizing carbon exposure. This has allowed us to double the size of our reduction while improving flow. Something that was not anticipated is there is a dramatic reduction is ash yield. We used to have to clean the ash out about every four hopper loads. This has about doubled, we can run all day and not have to worry about it.

This hopefully will be the last design revision for the M-Series for many years to come. We will continue to make this machine better and better with more advanced automation. This along with advanced manufacturing methods are what we are working on to get the 2016 M-I and M-II developed for retail. As soon as we get our manufacturing to this level and the electronics to make these machines self run we will approach retail sellers with this product. How cool would it be to see a gasifier on display at your local Cabela’s?!?!!

The ES- Models I am still working on. The ES-4 version is pretty well ironed out. Next is the 5 kW version, I am going work on reducing its cost dramatically. In order to do this I will need to design this with some options, an air cooled engine vs the very expensive liquid cooled option and also offer it in an AC version. The liquid cooled Kohler and all the components for the DC system is what really drives the cost of the current machine. I can cut the MSRP down to around 12k for this guy if we go with the less expensive air cooled engine and AC system.

Also in the pics is our ES-4’s massive reduction bell

5890.jpg" width=“648” height=“364”>

5890.jpg" width=“648” height=“364”>