I feel like a major issue with gasification is fuel processing. Is there a way to build a gasifier (stationary or on a trailer so room is not a factor), that will accept and burn through full split firewood chunks? What would it need to work?

As Steve has found an old post. LIke me, like you, we are not the first to think along these lines…

However there are ways to use firewood, Just not directly in a gasifier. If build a stove to accept typical firewood, it is possible to make charcoal on the fly for the gasifier. Think of it this way you get two for one. You only process for firewood, the stove processes that firewood to engine grade charcoal. You then have a simpler system that is nearly labor free.

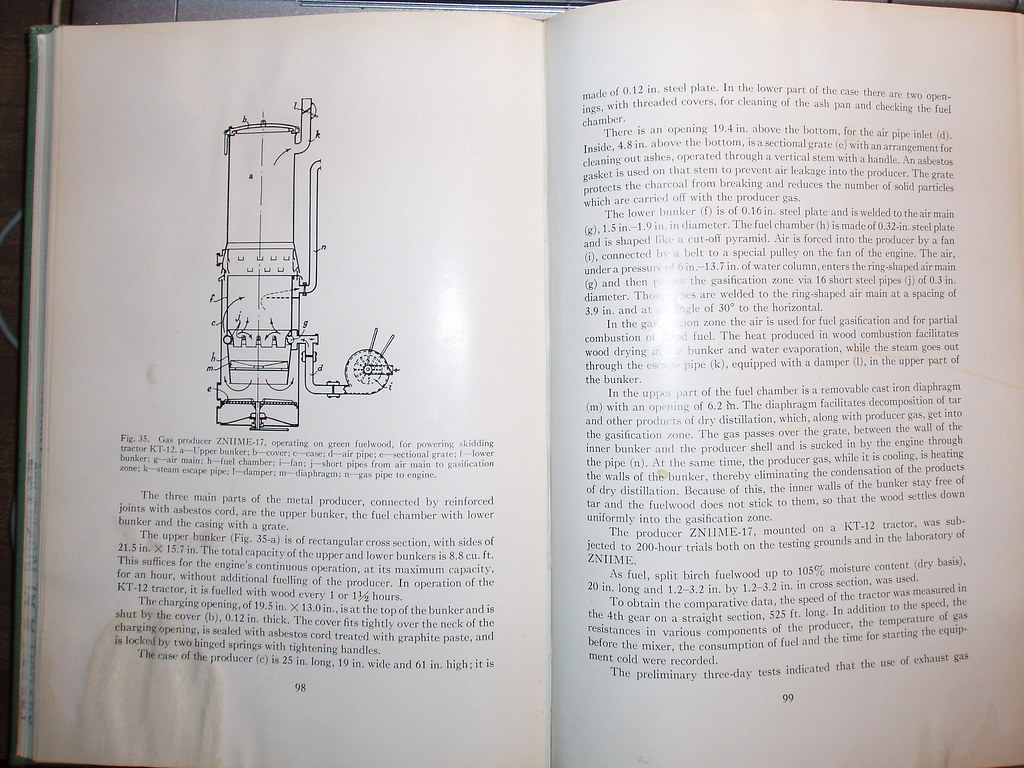

In the USSR, gas generators were made on logs, 50 cm long. The technology has been well developed. There was even 50% moisture in the logs. I read several articles about this on my channel.

Such gas generators worked on raw logs, in the forest to generate electricity, on cars and on ships. An example in the images is in the video.

why arnt we funding this?!

I am and have been driving almost free about 18 years .

If I were driving on gasoline funding would be very much appreciated

Excellent Sergei, excellent.

The second video thru CC can be audio word translated into English, and others. ~70% good words translated.

Guys. Well worth listening to this.

Lot of details of the evolutions changes to operate better on stick wood forms.

Serg did you ever find the missing sheet?

Best Regards

Steve Unruh

My English is weak). Specify what the lost sheet means.

Here is another patent for an engineer to operate a gas generator on a tree 50cm long.

Can work at 50% humidity.

So, basicly, its preety much a WK? Interesting. This has to be looked up more in detail.

Hello, Sergei

The voice reader man in this video has missing information he says is a missing sheet page.

Not you? You are not the reader, speaker? O.K. I myself, am only once Net heard. With great reluctance.

The information missing from the 1937 technical publication is the interest.

Interesting the critical judgments made from the 1937 to the 1950 patent system.

I mostly agree with these opinions.

Regards

Steve Unruh

Good Morning KristijanL.

Important to CC auto translate and read the narrators readings.

The 1937 much difference was found between conifer “soft” wood weight setting and crushing it own made charcoal. Versus . . . hard woods fuels species. The hard wood charcoal able to resists this weight bearing down crushing.

In the second translatable video the narrator comments on the system changes 1937 to 1950. Finishing reading comments the great ability to use 50% humidity fuel-in. Cries over the systems potential fuel vapors and even heat energy loss doing this system ejected away.

A different world we live in 1950, versus 2020. 1950’s possibilities, are 2020 impossibilities.

SergeiL.

In the 1950’s to 1970 we always put tires in the forestry wastes burn away piles.

One tire. Just one tire used in combustion today and I would loss the right to do ALL that I do.

The world of today is the world of cameras in every pocket. Instant Internet publishing out of any photo activities.

One burn pile by me in 2008 I put on 2 liters of used motor oil to get heat started. Neighbors cameras came out. Eco-Green-Spinners live every where, eh.

1 1/2 hours later the Air Authorities drove up. I was by then “clean” burning only site grown “natural vegetative material”. With a pre-registered burning permit.

I was still written cited/warning for NOT telephoning into them my actual time of activity.

Forcing them to drive to me to verify the neighbors complaint of forbidden materials burning.

Since then I Iet limbs debris piles sit dropping all leaf and needles for one year. Pull back out all pieces down to thumbs diameter (13mm). Lengths cut and burn up in my certified permit registered wood stove. Legally. My trees contribution for heating INSIDE, versus heat to the wild birds.

Old man keep busy hands labor. The same could be hand fed into a Polish-style chopper system to make clean pre-dried small gasifier fuel bits.

Kristijan what is not addressed in these old Soviet systems are limb knots woods sections; Y crotch wood sections. ONLY using the clear wood sections. Saw log sections! You know that these others, have variable devolution characteristics. Ha! So another waste loss: tree to shaft power.

Why I gave up on stick wood gasifing.

Accepted the step to make chunked gasifier fuel wood. Knots and Y crotch sections can be chunked up too. Just need more force and power.

Then gasifier easy control: and true as much as possible, full cycle use efficiency.

Here in the clean& green (a local joke) NO SMOKE must be made. Energy fed Moderns see water vapor steam as smoke. And the camera’s will come out. Complaints made. Reponses visits generated.

Regards

Steve unruh

I sympathize with you. The US has very tough and unjustified laws. Here anyone can smoke as much as they want. And in 2015, a law was passed stating that recycling enterprises do not need a special permit. We can sign a contract. They accept used tires with a surcharge from the supplier and are recycled. I am familiar with dozens of businesses that are paid in Europe to bring them tires. Like $ 200 per ton. They boil them to get fuel oil. Sell it and sell carbon. It’s too bad that you can’t smoke. Come and raise all those with us).

All pages should be in these articles. I shoveled about 600 books and magazines, making up a huge library. And hundreds of articles. This article is from the magazine. There is a 2-part video. I have recorded about 300 videos reading such articles and books. I don’t remember everything. But there all the pages are in place.

Yes.

Give me a nuetral mailing adderess in a PM (personal message here) and I will mail you my gifted to me 1940 published in the Netherlands all mobile gasification systems book. Written in Dutch.

Ha! All western European. No Soviets’ information. No Australian information.

A young man like I was in the 1970’s and you could expect a visit from me.

Now I live-on thru the young vigorous like you and Joni, Kristijan and Chris Seanz.

Regards

Steve Unruh

a charcoal generator with “reverse combustion” for tractor use.

After a practical test with such an equipped tractor, he founded AB Gasgenerator in 1929 in Örebro , together with some financiers . He became the company’s technical manager and in 1941 its managing director. The company was taken over in 1950 by AB Axel Svedlund and System Svedlund AB .

The company had only insignificant commercial success in 1933-1938, but at the outbreak of World War II in 1939 was ready with constructions well suited for truck use of charcoal units, which came in handy during the war years. Until 1945, about 35,000 units had been manufactured in the country according to System Svedlund.

Svedlund was granted 21 Swedish patents for its gas plant. In 1941 he was awarded the de Laval Medal of the Academy of Engineering Sciences .