Hi Eddy,

reading thru your numbers and making some reservations;

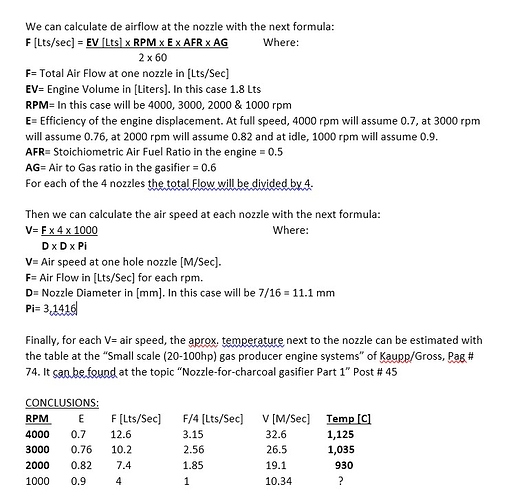

at 4000 Rpm with a charcoal gasifier with 60 mm water vacuum, you’l have about 0,35 efficiency

at 2000 Rpm max 0,5

at 1000 Rpm, idling not wot, about 0,09 depending your vacuum.

at 1000 Rpm , WOT, you have max 0,6

at any given time, the air coming thru the nozzle will accelerate after heating up, by heating from the surrounding materials.

At the exit of the gasifier you will have an increase of volume , calculated at normal condition, ambient temperature, of about 20-35% depending your gasifier.

Above numbers are not theoretical but extracted from my testings.

If the gas is “weak” then less mixing air is needed, if the gas is “rich” then a lot more air is needed.

The only way to “know” the real life numbers is to put given engine under load and or being able to measure so many parameters that the only fun you have is measuring  ( sounds as my job description )

( sounds as my job description )

About water injection, my humble opinion; just ad enough to overcome timing adjustments and or acceleration need.

Focus on filling efficiency instead on adding more water coz adding more water if not needed decreases your power if you don’t have AFR controlled. ( yes, the hydrogen also needs oxygen to releases its power. )

Eliminate restrictions between nozzle tip and intake valve… listen the engine getting its pistons kicked downwards; a “pow” sound is more powerful then a “tak” sound… ( if the sound start with a k, then its time to rethink strategy  )

)

all above in my opinion dough

( sounds as my job description )

( sounds as my job description ) )

)

)

)