im incorperating a thermo cracker unit in the gasifier to break down used oil into fresh gas/ diesel and saving those resources for later

Thanks for the pictures, we can see a little better what’s going on. A drawing of how it’s supposed to work would be very helpful. Your layout is very different from the standard setup, which is concerning. We want to see you succeed, that’s why you’re hearing this type of feedback.

I hate to be the one to break this to you… but I have serious doubts that your gasifier is going to produce usable gas. Here’s a short list of problems I see.

- Your firetube is very small for that size engine. I think Wayne assessed this correctly above.

-

Lack of airtight junctions. With that ash door and the barrels, you don’t seem to have airtight connections. That might work for a woodstove, but gasifiers MUST be airtight to function. Otherwise the gas will burn in the unit before it reaches the motor. This excess heat will destroy the gasifier.

-

I don’t see a grate. Not sure how this is supposed to work, but you probably need a grate.

-

I don’t understand the bilge blower on the bottom there. Is that your air intake? Regardless, it’s too near the heat and will melt.

-

Nobody here is able to help you with thermo-cracking oil into gasoline and diesel. You need a lot more sophisticated equipment than we’ve got to do that. Anything homemade involving gasoline is very dangerous. Please be careful.

So everything is airtight except the door. Thinking about buying a flange to make it a flat door. Although i don’t know where to aquire a rounded flange that would fit my barrel. its a 10 inch x 12 inch door. I do appreciate the feedback but try not to be so harsh and doubtful of my design. Im possitive it creates woodgas, at least enough to run my generator because i have ran it. as far as running my 454 i have not tried yet until i fix the door issue. The grate is under the biomass i have loaded in it so it is there. I have had fires exceeding 1500 degrees and have not had any issues with my fan melting, yet. I am trying to get this unit working perfectly and do some more research before i try the thermo cracker.

Nice looking motor home and i like the 454 motor,that is worth way more than $50.00 worth of design schooling,and the 75 percent operator education involved, no way i would chance bending the valves on a running 3000 $ 454 chevy motor, with a questionable suppply of maybe dirty gas with out the WK Tried, tested,designed plans with many 20.000’s miles without dirty gas engine failure.It would cost more probbly 500,$ too rebuild the upper end likely.

Philip, I doubt that you will be doing much showering when your driving so maybe try air cooling the Thermal Cracker. Have you found a good dial valve?

I’m trying to figure out what is going on here?

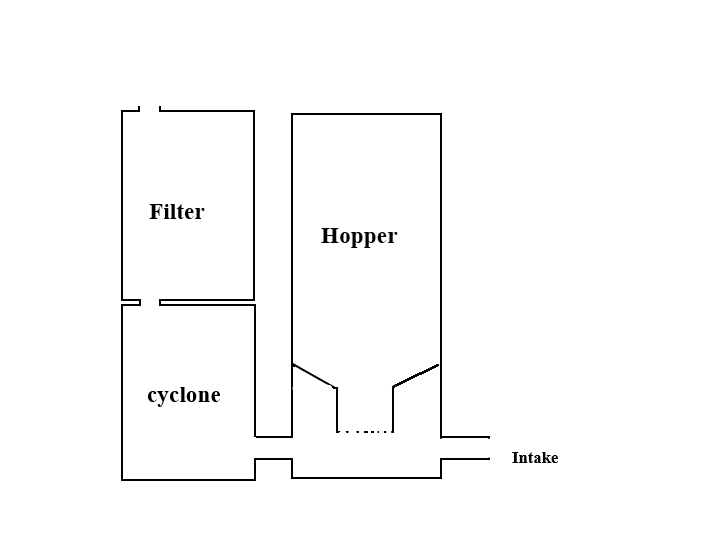

This is my design… Would it be better to have an intake blower, or an ex-take vacuum and why???

I like to have both. Mine are all Wayne Kieth style. I do not totally understand the route of the intake air. How is that design pulling anything through the char-bed?

Which one of these designs are best and why? I can run my current model either way at the moment but I need to decide what is better.

This one looks like it would make a whole lot of heat and no gas. Unless you’re piping that air to the air jacket of the hearth for the nozzles.

You need a grate and a opening or restriction opening for the charcoal to pass through in the bottom below the nozzle intake for it to work.

There is a lot more then what is shown here in your drawings for a good gasifier. Refer to some plans here on DOW that are proven to work and follow them. You will have a lot more secess if you do so.

Bob

Whats wromg with my design? I need help to figure this out. How do i run this help me with a diagram Please???

For starters, dimensions are very important for a gasifier. A 454 cubic inch engine will need a pretty big hearth. Also your drawings are a little too abstract to understand how you’re building them, there may be implied features we don’t see in the drawing.

This design makes the most sense if you wanted an answer, but like I said above it’s a bit abstract.

Good Morning ALL,

I’ve linked back up to Phillips October 2015 picture of his actually wood using to gasify his real 454 V-8 motorhome. From there scroll up and down for other actual pictures.

Best to scroll back up and see that he is not an armchair guy. A bored brainiac. But a serious intent, wants to be, drive down the road User/Doer.

O.K. Phillip what is wrong with your current four barrel chamber proposal is you are still giving equal importance to Burn/Gasify; Hopper feed that; Cyclone/Separate/Cool; then Filter.

Your order of make it work concerns should be #1 the wood fuel and and necessity to pre-chunk, and dry it down it for gasification effectiveness and controllability.

Then the better you have done that; #2 is the actual wood chunk gasification Hearth section design and building. Why very experienced man JanA posted up a diagram of one usages/time evolved, developed way to do that.

If your state license plate shown is correct be aware in that state currently now three guys are using and roads speeds driving on a different Wayne Keith derived woodgas systems. 318/360, 350 & 460 V-8’s.

So if you are truly serious about getting working results you will invest in source information about actual working woodgas systems.

Buy 1, 2, 3 books.

Sign up and join the DOW Premium side.

The better you do #1, the wood fuel pre-prepping; and #2 the actual hearth gasification of it . . . then the after gasifer hearth separation/cooling and filtering of your produced fuel gases will fall into place.

Regards

Steve unruh