If it wasn’t raining, I’d be out in the woods trying that board cutting technique. Nice find.

They all have nice long bars so the don’t have to bend over so far. TomC

Wow, that is impressive. I wonder how long it takes to learn that??

Ha! Ha! Two recounts I’ve read relates to, “how long to learn”.

The first from a book of Weyerhaeuser Co’s First Hundred Years.

In the 1930’s one of the Weyco’s 2nd generation then university ed-u-ma-cated managers was bemoaning having to go to the expense of convincing and rough-rail bring in craft finished carpenters to build some management company housing for the company Doctor, Bookkeeper and TimeKeeper at an end-of-line location.

The on-site Carpenter ask why? I can do this too. The degree manager was skeptical of this rough-carpenter. The Carpenter said you’ve stayed at the three-star Astoria Hotel down in Longview(WA)?

Yes.

Well. I did all of the finished carpentry on that.

Really? How?

With this belted carpentry hatchet you’ve seen me always carrying and using!

The second account was from here on the DOW.

Band-saw many teeth blades resharpening. Debated better to just buy the-cheapest and change out discard replace when use-dulled? When broken?

Or better to buy the higher quality bands. Then the resharpening fixture machines? Even invest into broken bands re-welding capability.

Ha! Mr Wayne finally pipes up and says he actual free hand dremel-tool resharpens his. But only on his best good-eye and steady hands days. Only discards out the broken ones.

Very much some woodgas system using lessons here.

Steve Unruh

Working on the next version. I’ve found that a simple perforated (or drilled) grate works best for me. The difference with this one is how it is mounted. Just welded to an old door hinge. Then it can be locked in place with a bolt or what ever, through the holes in the hinge. Makes for a nice swing away cleaning or some little cleaning by shaking the grates. One issue might be if the grate warps away or opens up some by heat warping. If it does I’ll worry about it then.

Swung closed:

And swung open:

Of course the producer is upside down in the above pictures.

With this version, I’m trying to keep the nice addons but simplified.

Hi Jeff, My retort/ gasifer I am building has the same design but it is a lot bigger grate to pass charcoal pieces. I am sure this will work. If it warps just weld some half inch metal stock around the edges of the grate and to the hinge to stiffen it up.

Bob

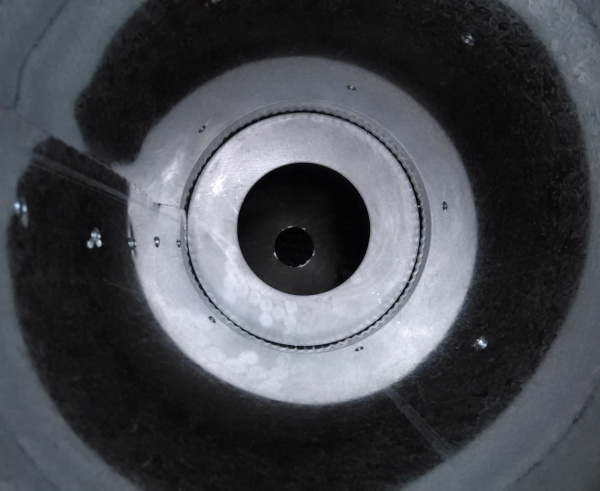

In the past I’ve purchase ready mix refractory from eBay. This time I thought to use two used fire bricks that have been stacked up outside looking for something to do some day. Using a masons hole drill to cut out the center hole, one brick at a time (half hole). Then a masons angle grinder blade to cut the round sides of each brick. Next, the two bricks were glued together with furnace cement. Since they were soaking up moisture, outside, the glued bricks were left drying above the furnace this winter. I suspect that they will crack but I’m hoping that the ash will fill in the cracks.

Some furnace cement was placed on the top, thinking that it would help protect the brick during the first firing. Now I kind of wish I didn’t do that. That could trap some moisture in the brick and cause small steam explosions and that could crack the brick.

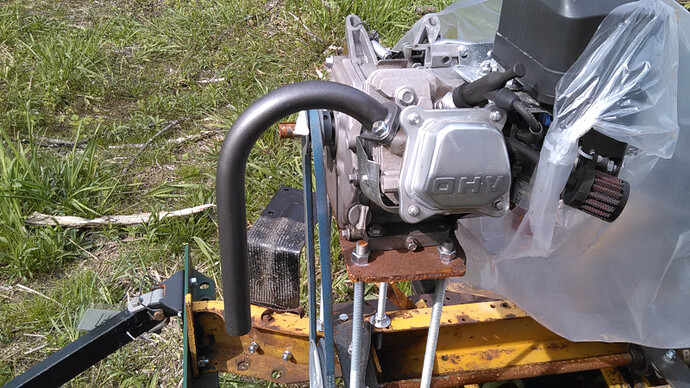

And here is the machine that it will be fueling. The new log hauler plus mobile generator.

I was going to put the gasifier behind the operator but now decided to place it on the front right hand side. To be honest, I enjoy building utility vehicles more than gasifiers. The tow bar will be removes, it was used to bring it over here.

I suspect the brick is porous enough that any moisture has found its way back out if you left it somewhere warm and dry all winter. I am looking forward to seeing it fired up!

Jeff, I think you are having just too much fun over there building stuff! Is’t there some kind of law against that?

I’m sure there is. The trick is to just navigate around those laws or regulations. I really like the looks of your new plasma cutter !

Scheming to build another charcoal grinder. Lucky to have an old chunk of pipe and a couple heavy washers. The washers were next to the short pipe buried under rotted leafs and stuff. Been there for at least 30 years.

When you freshen up your Detroits, make sure to keep the liners. Never know what they could be used for. Liner on left, pipe on right hand side.

New exhaust for the clone. Learned something. Don’t have muffler straight with exhaust port. Lots of rust from the muffler fell into the exhaust port. I blow it out the best I could but I better remove the new exhaust and blow out the exhaust port with compressed air. Exhaust valve is closed. Engine has been setting for about 2 1/2 years.

I’ll be missing for about five days, maybe read some posts, until then.

Before COVID, the hardware store had a sale on these soft tool boxes. Makes a nice place to store a blower, lighter, flame holder, homemade speed control, adapter and tape.

The gas tube manifold below. Slowly emerging is nothing more then my same old tricks just simplified and in stealth. Well, mostly. Will be interesting how it works out.

Below is the position limiter or snubber for the manifold assembly.

Working a bit backwards. I did not install the bottom refractory and ceramic insulation yet.