Now that thing looks sturdy enough  You could chunk anything. Keep us posted!

You could chunk anything. Keep us posted!

Great! Do you plan on charcoal powering it?

Keep us posted!

Looking good, I am next up too building a chunker, should make much easyer and not so lould sawing up chunks, wood chopping before cool weather returns.hopefully.

Bob if you need a couple days of woodgas experiance, but no chunkier experiance , let me know.

There is a lot of heavy metal there to deal with!

I still have not started my summer project, so am available until mid July

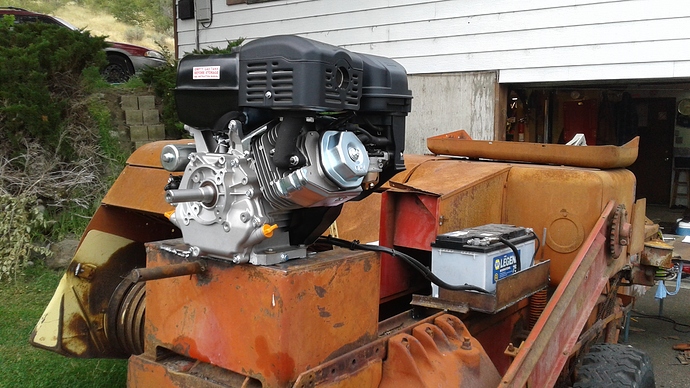

The unfinished wood chunker is back up in the driveway where I have been working on it. Cutting some unnecessary parts off of it.

Welded up the engine mount for it and will be placing the engine on it tomorrow and battery box.

The next step will be getting the engine running the gearbox with belt drive and watch it go around and around.

Bob

It’s running, well the engine is running. Ran the Predator 420cc for 4 hrs. No load, low idle to half way throttle.

Still waiting on the pully and belt it is three belts in one piece. Coming from Kentucky of all places.

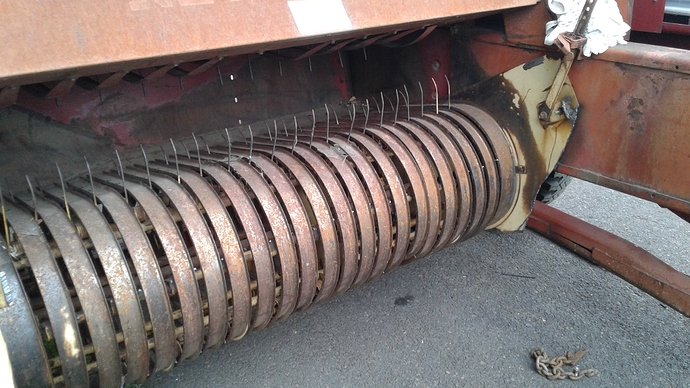

I have been cutting off pieces of steel that is in the way. I have decided to try and keep it looking like a bailer, around here we do not have to license farm equipment so it is going to be a Newholland (modified square bailer) Wood Chunker.

The rotor rake will be removed and a covered wood storeage area will be built in that spot all the way to the back. It will chunk the wood and put it in the storeage area. Kinda like what @JO_Olsson does with his rebak and trailer set up.

I will beable to go to the Orchard piles and chunk the wood and bring it home. Lots of orchards have wood they have to burn every year. All free fuel if they do not have to burn it. I have a huge pile to go though before I will need to go looking for more wood.

My opening will be in the side of the bailer, I will be making a flat blade cutter and have it auto feed for short pieces of wood, and manual feed for long pieces of wood. It makes me nervous watching people freed short pieces of wood in to these chunkers. Safety, safety, safety comes first.

Bob

Sounds like a nice setup. Now will you include a sack filler attachment?

Hey Bob, That thing is a beast! Free orchard wood scraps? OK, twist my arm, oh stop! OK, I’ ll take away that scrap wood for you! ( In my portable wood-processing center).

In Minnesota, we don’t need to license trailers for a specific duty. Welders, air compressors and water jetters for an example.

Hi Andy, it is high enough for the wood to come out the bottom after cutting and slide into several bag holders that will be built into the floor or bed. If the wood is dry bag it if it to wet put it in the bed to dry. Like JO does in his trailer. A conveyor belt will move the wood up into the back of the trailer. Goal here is to save energy when processing the wood, and my back, “Getting Old Is Not For SISSIES.” But I try to be smart about it.

They have big pieces of stainless steel scrap at the recycling yard could use that for the botton of the bed.

Bob

My belt for the Wood Chunker came in today so I got busy putting the pully on and building the retention pully to keep the belt tight. I used a water pump housing. Cut the pump blades off, and bolted it to some heavy steel, used a sping to keep tension on it. A piece of T fencing post used for the leveage arm.

Started it up and it runs great. At full throttle the blade will turn one revolution per second. That is just right, I didn’t want it to turn any faster. Still need to build a belt cage around the fly wheel and pully. Time to start cutting some parts off the New Holland for building materials.

Now I can start on my sprocket and shape the cutting blade put a edge on it, and then weld it on to the out put shaft arm. Also plan out the anvil and wood exit bag shoots.

Bob

Totally Excellent!

One question and a concern: Where did you get that big toothed belt?? and… Make sure you dis-engage all the unused parts of that baler ASAP. We don’t want anything important to get caught up in there!! (I was thinking the rotary rake to start with!)

Hi Mike, yes the main drive chain has been removed. So the rest of the bailer mechanism can not operate. It is missing a lot of parts and is rusted up . Other drive chains have beem remove also.

The CTH 3/BX 100 belt is designed that way to run cooler and to give it more flexibility. I am running the belt around 2.8" pully. The solid belt would not rap around the pully unless you put alot of tension on the belt. The belts are a common belt. Thanks for your concern, I like the fact that there are people like you aways watch over my shoulder, for safety and for helpful reasons and just to learn from one another.

Bob

Bob,

I’m watching your chunker come to life intently. I’ve got the very same baler at home on our farm. I bought it from a friend that no longer used it. He brought it over and parked it in my shed one day 25 years ago. He said just pay me when you get around to it. I paid him thinking I’ll probably never use it, I always baled round bales. I know now why I ended up with it…I will be interested in your latest patent…there is always a lot of great thinking going into your machines.

Bryan

Pretty sure I will use a16hp opposed Briggs & Stratton that I have and a Simple -Fire to fuel it.

Excellent progress

Do you plan on keeping the belt loose enough to not stall the engine on a tough chunk?

Also a lightweight engine cover, say a large plastic storage bin when your not using it.

That large sprocket should be strong enough to resist the bending forces

Hi Bob, That will be a nice chunker. What a heavy flywheel! I really like the Predator motors for charcoal gasification as they work well for me. I have even bought a few to keep on hand since they are so cheap. You should have no problems getting your unit to run on char gas and enjoy “chunking on charcoal”

Gary in PA

Hi Gary, that’s good to know about charcoal gas for it. I started building a Simple Fire Gasifier the other day, that will work great for that engine. You gota love that charcoal.

Bob

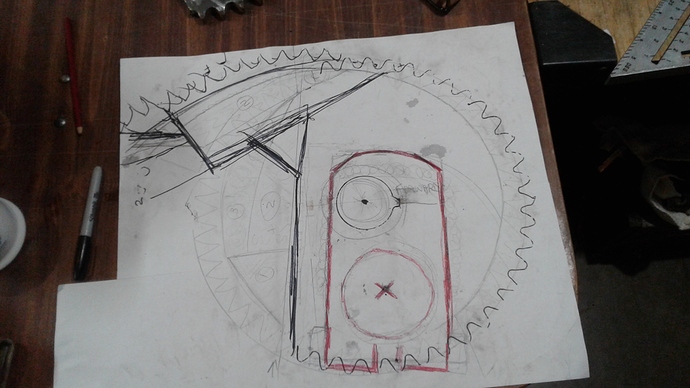

Jumping back on the Wood Chunker Project I started making my cutting blade out of the sprocket. Now the sprocket was not big enough for what I wanted it to do, so I made it bigger by cutting it and rewelding it. By set it off center from the turning shaft I have made the sprocket cut in a spiral cutting action. It should be able to cut up to 6" plus, not sure if I want to go that big yet with my wood stock. But nice to build it in case, I see a need for it.

Here are some pictures to show you what I’m talking about, so it will be a little more clear.

This was a pretty nice sketch until I spilled water and had the dirty sprocket on it and then changing mind on how I was going to cut up the sprocket. A lot of redrawing.

The sprocket teeth will be cut down to where they will be a serrated edge. On a 45* angle on the back side of the blade. The heavy duty anvil box will be on the front side of the blade.

Still need to find some material for that. Back to the salvage recycling yard. They are getting to know me pretty well, I only buy from them it seems.

Bob

@mggibb, I went out and looked over the tension set up on the belt. I can lift the lever with the spring on it and make the fly wheel slip on the belts. But I think if I would want it to slip under a heavy pull on the pully, I would need the tension set up to be on the top side of the belts. The pully and fly wheel turn counter clock wise and I can’t see how the tension set up would release under load the way the belts are pulling straight off the pully to the flywheel.

What do you think?

I do not want to stall the engine or break the flywheel shear pin or bolt just because I put a big hard piece of wood in it. I am planning on adjust the anvil box so this will not happen but you never know about some woods.

Trying to get this Wood Chunker finished up so I can make a lot of prepared wood for the gasifier truck. I can’t keep up on the wood prep unless I just don’t drive the truck.

Get er done.

Bob