Hi bob mac nice working chunker, i am not sure what your cutting blade arangment is i am looking , my phone is slow loading pics, back looking for final blade detail. Ok i see the blade, it is hard too tell the size around the blade is? i gess its off set conected too the arm for the cutting action.Thanks for sharing this design, i think i will try this type cutting arangment and see how it works, it seems its useing the bearing load the way it was designed.

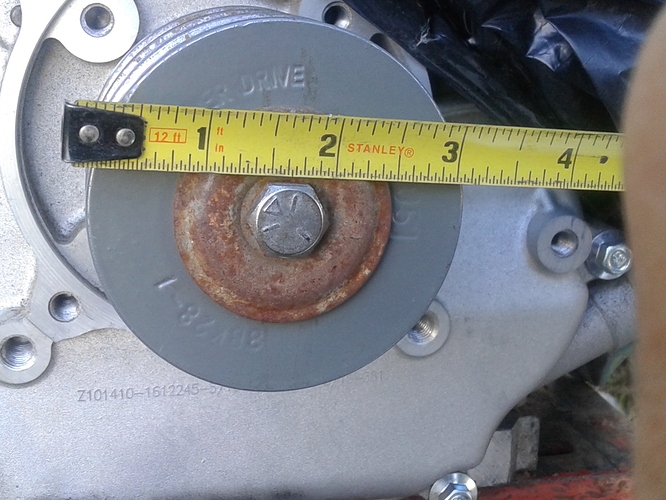

Hi Kevin, here are some pictures of the fly wheel and pully system on my build.

Hope this helps.

Bob

Thanks bob on the pulley gera ratios and big pulley size, And thanks for the neat vidios on your chunker, Did you have any problems getting the wood chunks too fall past the gear box, cutting with the blade and no pipe for cutting force in other direction.

I decided to do some wood chunking today. I have let the wood pile sit there all summer drying. Burned some of the larger pieces in the fire pit making charcoal. When I chunked some bigger pieces that were 5" to 6" diameter I test the them with the moisture meter. 30 % + right in the center. The 4" diameter was around 5% to 15%, smaller pieces were 1% to 5%.

Some of the larger pieces were good to go into the gasifier. Go figure. This wood was all pruned at the same time. Two hours of work taking wood out of the pile and putting the wood through the chunker produced a few bags and more on the ground drying. The pile is 9’ × 6’ and about a 1’ deep in the middle.

Still have a lot of wood to chunk but I did make the pile shrink a little.

That pile will make 6 more of the chunk pile.

Bob

That is some gnarly wood for chunking, hard to get out of the pile and must kick a lot when feeding it.

Your chunker really splits the chunks well, should dry quick and burn hot.

My chunker would have stalled on any of those pieces, unless green 30%+ mine will stall at 1 1/2 inch

With the right camera angle your chunk pile resembles Wayne’s

Good morning Bob Mac,That chunker chunks some big branch’es, im with Mike gib, mine stalls on smaller wood yet, do too our drive motor is about half what should be too chunk full speed ahead,I snaged a 4 horse double caps off a air compressor at auction yesterday for about 35 bucks including the auction 16 percent sale charge,how is your gas motor working, should i say is that a good enough size gas driver, or are you thinking bigger or smaller gas motor next time,change.Thanks for the wood chunking wood check.

Hi Bob, don’t you just love how the wood fractures to almost like a loaf of bread! Put that high moisture stuff out in the sun for a day or two now and it will be down in the ‘‘driving’’ range. I use dead trees that have fallen. Even though they have stood for several years dead, when I split the wood for fire wood, it is still too wet in the center to burn right away. TomC

Hi Bob Mac,

You are proving well that wood most rapidly dryes out of the end grain versus the outer-edge cross grain layers.

Double reasons be best to chunk up early while still green n’wet.

S.U.

Hi Tom, yes it really Fractures the wood as long as it is not to green. Even in this dry cold air it dry out as long as it doesn’t rain on it. When it is green very little fractures are formed, that brade just slices through the 5" and 6" inche pieces. The dried out dead wood fractures into pieces.

Bob

Hi Michael, my fly wheel is a heavy one. This bailer was a gas driven one, not a PTO driven one. It also produced the longer hay bails with wire tie. I am using a 10 hp. The wood from pruned fruit trees is gnarly indeed, this is why I chose the straight blade. But you half to hang on to the wood, it can jerk around.

Bob

Hi Steve, you are Right about that. 6" dia. Dried out wood will shatter into many pieces, but with a little moisture like 21% it cut it nice with fractures. We are blessed with low humidity in the fall for dry wood. But soon the rain and snow will come to stay.

Bob

Hi Kevin, I think a 4 hp. Is a little small for the big pieces I am chunking. I am full throttle when chunking the big ones and with smaller pieces I can run it idling. It doesn’t slow down at all.

Bob

Excellent DOing-it reporting BobMac.

S.U.

Good evening Bob mac, thanks for the out come of your design and motor sizeing, Im getting good help on how too build my chunker from what i got here, Thanks again for the nice chunker build post. Now that winter is getting closer, it still looks better than that heat wave the poor southern folks got this year.If it gets too cold too long we may have too become snow birds and fly south a few mounths.

Good evening Bob Mac or morning witch ever comes first, i have a QUESTAIN about you chunker, it appears the rest of us chunkers designs are rotateing the flywheel in the opposit direction of the way it was design, witch too me that posses a week point in the system, I beleave your design turns the rotation direction it was built too turn. ?

If I may Kevin, the reason is, if you turn the cutter the direction of original rotation, you will have to stand within inches of the flywheel, and drive shaft(if running off of a pto) while feeding in the wood.

Mine runs the direction It was designed to.

i know what your saying is true , im just not quit sure its the best way too use the gear box set up, another problem i see is we are pushing on the shaft with the bigest bearing, though then that means were pushing the hole shaft over too the little bearing on the oppisit end’ Efectivly not useing the big bearing pushing it out of its race. ?? just analizing some facts if in fact this is likely the case. I beleive this is why Bob Mac used his gear box the other way. JUST CHECKING ABOUT GEAR BOX DESIGN. Not going too change any thing , like you say space is tight too drive motor and pulley the other direction. I Think Bob Mac turning his the proper way and cutter without the pipe type cutter. But that looks aufull short on space on my gear box.

Hi Kevin, I mounted the new engine the same way that the old one was mounted. So I pretty sure my is turning the same direction that it ran as a hay bailer, unless the old engine on it rotated the opposite direction.

Bob

There should be an arrow on the front if the counter weight to show rotation direction. But as you stand infornt of the implement and look af the counter weight it will rotate counterclockwise.