Specifics of a language.

Effective compression ratio, poor choice of wording on my part because this confuses things.

Effective meaning what the actual volume of gas compressed.

What I mean to say and what I type can be confusing and I am sorry about that.

What I do know:

Use the 14cc head, and the Z4M piston and if memory serves me it give you a calculated compression of about 11.5:1.

In reality there are different thickness of head gaskets and tolerances that change this.

The restrictions in the flow through even the best engine mean the effective ratio will change from the calculated.

Cylinder pressure is going to change with load and rpm and the volume efficiency of the engine.

From my previous experience the stock cam will allow this engine to make the highest cylinder pressure around 2500 rpm and extract the most from the fuel charge.

Racing cams moves these numbers around and these are not going to be of use here at all.

There may even be some advantage to using the factory Honda GX160 cam.

I have not measured its profile, but I suspect its a little different looking at its lobes.

Non of this matters with these engines however.

I doubt they can detonate at ANY rpm because of the high antiknock property of the fuel and the low effective compression ratio at all rpm.

What you do want to achieve with a modified small block Honda here to reduce the restrictions to flow as much as possible and make the maximum of the fuel/air charge you can draw into the engine.

You can go even higher I suspect without issues of detonation.

But you will get into higher losses from pumping ( sucking air in/out and compressing ) without much gain in power at some point.

I honestly do not know where that point is.

I doubt a Honda rod will suffer from the high compression because the engine does not make much power.

At about 12:1 I am guess what will happen but I do not think any more power can be extracted by trying to increase the compression.

I do think a better exhaust is a good idea.

The stock one is awful and restrictive.

If you can make something about 20mm inside diameter with a smooth transition from the head to the manifold.

Same goes for the intake.

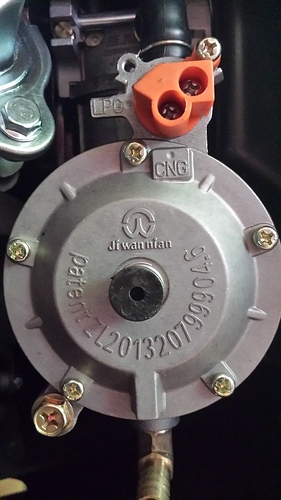

The Honda air filter is very restrictive and I suspect the volumes of air required might mean you are better off making a completely new gas mixer rather than trying to adapt the OEM carb as some sort of mixture.

Hydrogen as I understand things is very fast burning and low octane.

CO with its high nitrogen dilution is slow burning and high octane.

Adding water makes the gas richer and faster burning.

You may be compensating for a lack of timing by improving the fuel when you add water.

It would be an interesting test to see if some timing changes would have as big an improvement on the power.

How much of the increase in caloric value of the fuel is coming from steam?.

As side note I have noticed that Aviation gasoline ( 100LL ) burns more slowly that racing gasoline.

I blend my own fuel at around 94 octane that burns faster and makes more power.

Slow burning needs to be compensated for

I cringe to post this video because its not a producer gas engine.

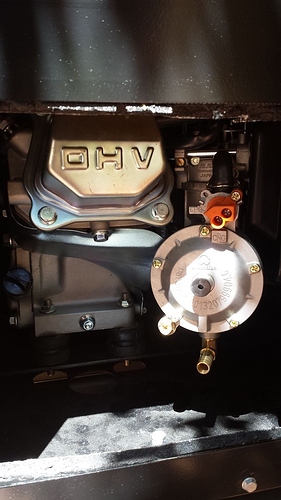

But it is a pretty darn close in actuality to the build I suggest.

Same head and piston I have talked about.

A very free flowing exhaust and intake without any of the restriction.

Maybe this could make 4 or 5 hp?

I don’t know.

Down the road a little and there are some clones with displacements of 208, 212 and 223 in production right now that might be better engines for this ( there are combinations of stroke and bore with heads that can flow more ).

Lots needs to be done to find out how the engines can be adapted to the fuel.

I will post some part number for the piston for you when I get my log book out.

It’s -10c in the nickle city and my clone powered 1974 snow thrower has a broken drive axle bushing with snow in the forecast.

It has a clone made of scrap motors and a compression of 10:1 and some cast off speed parts.

It has reliably cleaned the snow around my home for a couple of years now.

Neighbors comment on how far if shoots the snow and are annoyed by the noise.

I really enjoy working on clones…