HEY GASSERS, I BOUGHT TWO STAINLESS BARREL,S OVER A YEAR AGO FOR 50.00 EACH, THEY DO NOT HAVE REMOVABLE LIDS, I HAD A TOP LIP SECTION OF A BARREL I HAD CUT APART, SO I DECIDED TO WELD IT ON TOP OF THE STAINLESS BARREL , I PLAN TO USE IT FOR THE STRAW / HAY FILTER. IT TURNED OUT A LOT BETTER THAN I THOUGHT IT WOULD, THE PHOTO,S ARE OF IT. THE PHOTO OF THE BOTTOM OF THE BARREL SHOWS THE 3 INCH DRAIN AND CAP, I ALWAYS WELD A LARGE NUT ON THE CAPS SO I CAN TAKE THEM OFF WITH A SOCKET WRENCH.

Ah David

Your welding always makes me green with envy

I do a lot of heavy stuff but it’s been a while since anything thin

I need to get back at it hope i’m not to old to relearn LOL

Nice job

Tom

Looks good David. I guess this answers a question I had about welding SS to mild steel with regular mig steel wire?? Great idea about welding the nut on the cap too.

cz

You got a heck of a deal on those barrels! I spent nearly that much on refurbished steel ones. Nice work.

hey tom , i am glad you did not see me welding these thin barrels about a month ago. i thought i was going to need to buy a 110 welder, or something ? i worked 6 hrs trying to weld two half barrels together, and ended up scraping one of them and starting over with a thicker barrel. i was really flustered. but practice does make perfect. i found that if i move my puddle faster or set my welder on a 5 second pulse, i can keep from burning thru.

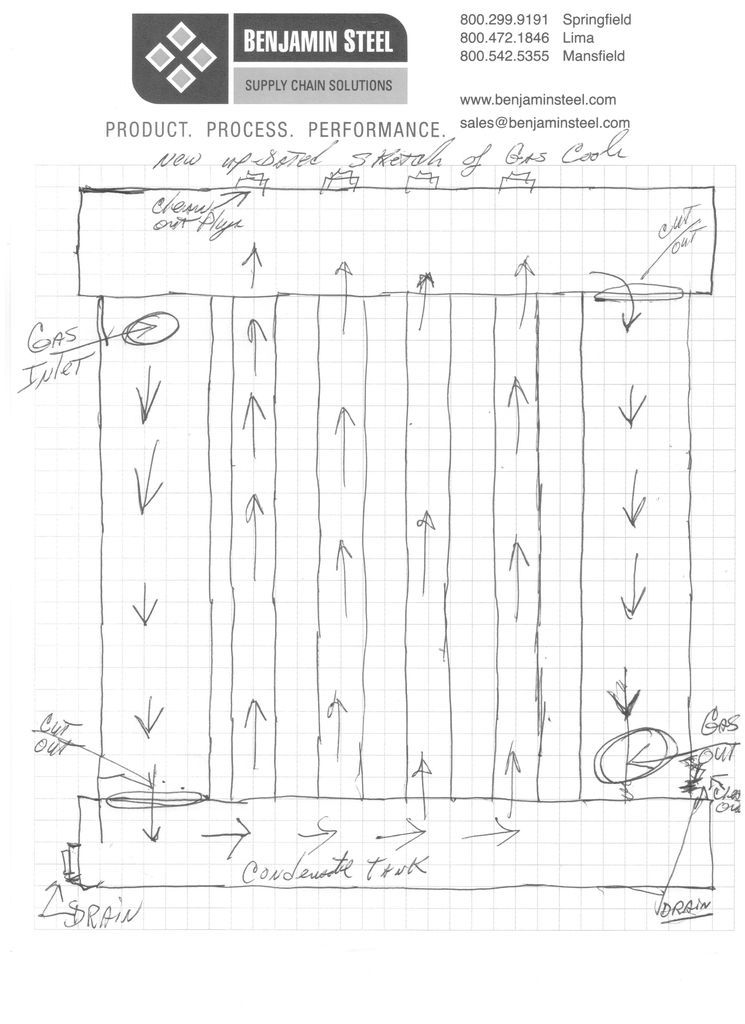

HEY GUYS, I AM GETTING READY TO BUILD THE GAS COOLING RACK FOR MY TRUCK I NEED SOME ( IDEAS AND OPINIONS ON HOW THE BEST WAY TO BUILD IT ) I WILL POST A ROUGH DRAWING AND SOME PHOTO,S OF MY MATERIALS. THAT I HAVE. THE VERTICAL PIPES ARE 2 1/2 INCH DIAMETER AND WILL BE 30 INCHES LONG, THERE WILL BE ABOUT 20 OF THEM I THINK ? I BOUGHT SOME CLEAN OUT ,S AND PLUGS, BUT LOOKS LIKE I WILL NEAD SEVERAL MORE, WAYNE TOLD ME TO BUILD IT SO THE CONDENSATION WILL DRAIN OUT AND SO I CAN CLEAN IT OUT ,

Good morning Dave,

On my coolers I try to put the gas in high and have a down hill grade all the way to the condensate tank (most of the piping are horizontal but the truck will be operated on different grades and inclines)

There is no place in the cooler for the water to puddle.

I make sure I have plugs so I can insert a small garden hose for cleaning of every pipe. I use ¾ inch plugs for the cooler and 1-1/2 or 2 inch for the condensate tank drain.

On your design it looks like your 5x5 tube at the bottom of the cooler could serve as a condensation tank.

HI WAYNE, THANK YOU AGAIN, I DID NOT THINK OF MAKING THE BOTTOM 5X5 INTO A CONDENSATE TANK, YOUR ADVICE IS SAVING ME LOTS OF TIME AND MATERIALS,.

Dave,

What is going to be your provision to drive the gas up the round tubes. Your flow arrows on your drawing don’t show anything like that. Some kind of baffles I think are going to need to be put inside the 5 x 5 tubes to drive the gas up at least a portion of the tubes from the bottom 5x5 square to the top one and then back down from the top to the bottom and then back up out your exit square tube. I think Max across the pond always says up travel on all vertical type tube coolers so as the gas cools the condensate is always running down making your cooler somewhat self cleaning. If you look at some of the old schematics of units with vertical coolers it seems they do like like a 1/3-2/3 type thing like 2/3 up and 1/3 down, but I think alot of those coolers were also front bumpers. But then again you know what? I don’t know YET as I am not officially an operator of a gasified vehicle, but getting closer.

David S

HEY DAVID, I HAVE BEEN THINKING THE SAME THING ABOUT THE GAS FLOW, IN THE COOLING TUBES, THE PROBLEM IS I CAN NOT FIGURE OUT HOW I WILL BE ABLE TO CLEAN IT OUT IF I PUT BAFFLES IN THE 5X5 TUBE, UNLESS I PUT CLEAN OUT PORTS ON THE BOTTOM OF THE BOTTOM 5X5 I KNOW HOW TO PUT THEM IN BUT DO I THEN HAVE A PROBLEM CLEANING THE SOOT OUT LATER ? WILL THE HEAT IN THE GAS NATURALLY GO UP, TO THE TOP OF THE COOLING RACK ? AND THEN THE COOLER GAS GO DOWN AND OUT THE OPOSITE END EXIT. 5X5 TOP EXIT ??? THANK YOU FOR YOUR INPUT AND GREAT COMMENTS, IT KEEPS ME THINKING OUT OF THE BOX, THIS IS ONE REASON I HAVE DELAYED BUILDING THE COOLER IS THAT I WANT TO DO IT RIGHT THE FIRST TIME

Dave,

What I would be inclined to do is leave your gas inlet where it is at in the left side 5x5 vertical tube. This tube would be isolated from the top 5x5 horizontal tube, and only cut out and connected flowwise to the bottom horizontal tube. The right side vertical tube I would move the gas outlet to the lower end of that and like you did on the right side only connect it to one of the horizontal tubes it being the upper one. Keep it unconnected to the lower. And when I say unconnected I don’t mean you can’t weld it just don’t cut it out there. Then all the gas should come in the leftside vertical go down into the lower horizontal and get dispersed up the round tubes to the upper horizontal flow to the right and down the right side vertical and on out. You would probably want to put a drain plug in your right side vertical as it won’t be connected to your lower horizontal in anyway that would be doubling as your condensate tank. Maybe you could connect it but with just a 1 or 2 in pipe with a ball valve so that any condensate can be drained from the rightside vertical tube into the lower horizontal tube but still be isolated for proper flow. As far as heat naturally going up, IMHO I don’t think it will work that way. With all the suction your going to put on it I think it would take the path of least resistance and go straight across the bottom unless you force it to go up.

The other thing I was going to mention and forgot was it looks like your vertical round tubes are stainless? I was going to use stainless and picked up on hints from other posts not to as stainless does not disipate heat like carbon steel but rather holds it. I think Steve Unruh had said something about it. Anyway I made mine with stainless horizontal tanks, and carbon steel vertical tubes for this reason. Of coarse with all the surface area your going to have with the volume your going to have in this monster maybe it won’t matter. Again though I am not officially an operator YET. I don’t even want to sign SWEM or BBB cuz I can’t do that yet. Can’t wait till I can!

David S

HEY DAVID S. , ALL GREAT INFO AND IDEAS, I MAY LOOK FOR SOME CARBON STEEL THIN WALL PIPE, I THINK KEEPING IT ALL THE SAME MATERIAL MAY BE A BETTER IDEA. I JUST HAVE A LOT OF STAINLESS ON HAND, BUT I THINK I WILL KEEP IT FOR A LATER PROJECT, AND MAYBE BUILD AN ALL STAINLESS COOLER ??? SOMEDAY ??? I MADE ANOTHER SKETCH AND MADE CHANGES TO MATCH YOUR IDEAS, THANK YOU FOR TAKING THE TIME AND EFFORT TO HELP ME ON THIS, I PLAN ON SPENDING ALL DAY SATURDAY BUILDING THE GAS COOLER / CONDENSATE TANK COMBO, THE 5X5 TUBING AND 20 VERTICAL TUBES WILL SLOW THE GAS VELOCITY DOWN I AM HOPING ENOUGH TO COOL THE GAS GOOD, THEN I WILL HAVE THE STRAW / HAY FILTER SETTING ON THE FLAT-BED AT THE GAS EXIT.

Hi DaveO

I completely agree with DaveS’s plan with a couple of additions.

The gas will still be hot enough coming across the lower manifold tank to resteam the collected condensate. Some verticle tube cooler people like DJ, Werner and Vesa plan for this as additional wash down. 'Donknow whats going to happen in your case. Too many unknowns. PLAN (means make the porting while everything is still clean and weldable) to contiuosly gravity drain out the pooling condensate into a lower sealed condensate collector as Mr Wayne does on his systems. As far as I can see he intentionally does NOT re-steam condensate.

At the very least put 3/4" pipe nipples with plugs above each down tube in the upper manifold. AND put big 4" clean out caps at both ends of the horizontal manifolds. Maybe overkill this time, but on the next one with operations experience you will then know what you actually will need.

SS is OK for coolers. But actual experience (IISc and others) says you must then ~30% oversize compared to carbon steel for the same heat transfer.

Since on this one you are already committed to carbon steel 5x5 manifolds . . . well you decide. You could always cut out and retrieve the SS vertical tubes for reuse later. THIS is what is nice about SS for woodgasing: costs more initially but then 70-80% of the metal is reusable for later modifying. Woodgas/woodstoving exposed carbon steel is usually 100% scrap unreuseable after only a few hundred hours of operation! Just ask those who’ve tried.

Regards

Steve Unruh

Thanks Steve. I thought you had said something about heat transfer in SS vrs MS. Thanks for the adder to a seperate condensate tank as well. That makes total sense, and I guess I heard that before but had forgot. It will save me some headach as I am doing a vertical cooler also. I went with stainless tanks on mine that are flanged with a MS core that is also flanged so the tanks just bolt on. I was worried about getting the heat tranfer in the compact space I have to work with. Also this way I can just do a re-core like we do with radiators. The whole core with lazer cut endplates and the straight lengths of 2in exhaust tube I used cost me somewhere between 50 and 75 bucks. I cut the tube and welding the core together in about 2 hrs. Cheap enough for me! Now I just wish I had more time on my hands over the summer to get 'R" done!

David S.

IT RAINED HERE FRIDAY, WE ALSO HAD A TORNADO WITH STRONG WINDS, IT BLEW A LOT OF TREES DOWN. IT WENT FRPM 103 DEGREES DOWN TO 70 IN A SHORT TIME. I GOT UP EARLY WHILE IT WAS COOL AND STARTED WELDING UP THE GAS COOLING RACK. IT IS NOW BACK IN THE UPPER 90 .S SO TIME FOR LUNCH AND A BREAK. I TOOK A FEW PHOTO,S I KNOW THE COOLING RACK IS OVER KILL BUT I AM NOT GOING TO HAVE ANY PIPES GOING AROUND THE BED.

David, I too was welding my cooling rack when the storm blew through. It is the same one that hit you…I am about 60 miles due west of you. Lots of trees and several barns down around us but no damage to our property. Glad you made it through OK. Been following your work on the cooling rack. It is coming along nicely. I will be posting some pictures of my cooling rack soon. After several months of work it appears we are still on the same pace…slow and steady! Stay cool.

HEY JOHN, GLAD TO HEAR YOU ARE OK TOO, I THINK WE MAY HAVE HAD SOME MINOR DAMAGE TO OUR BUILDING AT OUR BUISNESS LOCATION, WILL CHECK IT OUT MONDAY. MY SON IN-LAW THINKS THE METAL ROOFING MAY HAVE BEEN PULLED LOOSE AT ONE CORNER, I TOOK A BREAK IN THE MIDDLE OF THE DAY, THEN WORKED A COUPLE OF HRS WHEN IT COOLED DOWN A LITTLE TOOK A COUPLE PHOTO,S I BOUGHT SOME 3 INCH EXAUST PIPE FOR THE VERTICAL PIPES, SO MY GAS COOLER IS 100 % MILD STEEL , NO STAINLESS THIS TIME, I HOPE THIS WILL COOL THE GAS ENOUGH ??? I HAVE ENOUGH STAINLESS TO BUILD A COOLER BUT HAVE BEEN TOLD BY EVERYONE THAT MILD STEEL IS BETTER FOR COOLING

HEY STEVE, THANK YOU FOR YOUR INPUT ON THE CONDENSATION , RE-STEAM PROBLEM, I WILL NOW DRAIN THE COOLER INTO A CATCH TANK UNDER THE FLAT BED ON THE PASSANGER SIDE OF THE TRUCK. I DO PLAN TO HAVE CLEAN OUT PLUGS EVERYWHERE, SO I CAN CLEAN THE COOLER WHEN NEEDED, YOUR ADVICE IS APPRECIATED VERY MUCH DAVID-O

I’ve been looking hard at pics of Wayne,Terry,Dave and others cooling racks and wondered how and where the woodgas is plumbed in.Are all three sides used? Is the gas brought in one end and drawn out the other? Any pics or drwings would be appreciated if allowed.

Werner told me that every time the direction of gas was changed,more water was removed from the gas so to my understanding there would be more baffles in the manifold 5x5’s to send the gas up two tubes(for instance) and down the next and so on.