Another Run

Last night, I decided to do another run of charcoal. This time, I just cut the wood into 2 foot long strips, and packed them tightly in the grease barrel.

It was fun firing the retort at night. I could see the flames and the glow of the barrel much better.

I could also see the gas jets shooting out from the bottom of the inner barrel better.

The only thing I did differently this time is that about 1:15 into the burn, I removed the chimney and added some more wood to the outer fire. I was hoping to make sure everything completely charred inside. This extended the total burn time (including gas venting) to about 3 hours 15 minutes.

I was also tired, and we had to get up early for Sunrise Service this morning, so I decided to do a final test. I left the retort intact, and just blocked the main air intake hole with a piece of tin. It was not airtight by any means. I wondered if the charcoal would burn up overnight since the inner barrel was still sitting on the bricks.

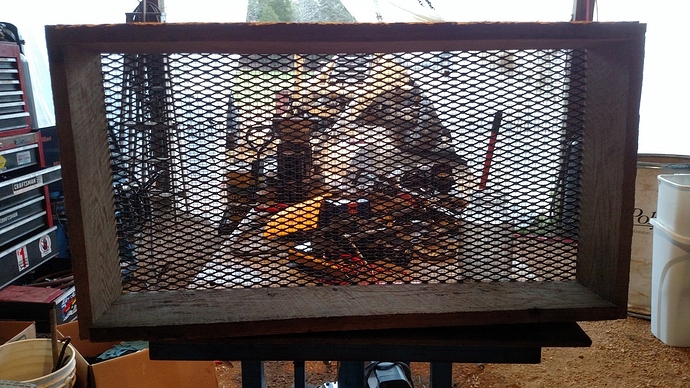

I opened it this morning after Church. This is what it looked like.

As you can see, there was some light ash on the very top (the bottom, while in the retort). However, it didn’t amount to much. Perhaps a couple of ounces of ash. The yield also appears to be somewhat greater than the first run, perhaps because the wood was more densely packed.

After I stirred the charcoal a little, and broke a few pieces to see how it felt, this is what it looked like.

My preliminary conclusion is that this turned out to be even better charred than the first batch, and that the “long stick” method works, so there is no need to cube up the wood.

Still, there is a lot of labor involved in wood prep., and this method isn’t really practical for continuous operation. I am going to have to reduce the prep. time considerably, and increase the batch size. What I am thinking about doing is using a 55 gallon drum for the inner barrel, with a bigger surround of some kind around it. I hope to be able to put 3’ sawmill slabs directly into the 55 gallon drum without any extra processing. If that works, then I think it would be a pretty efficient system.

I also think that adding burn-wood half-way through helped. This is somewhat wasteful of wood, but makes it more likely that I won’t end up with uncharred pieces. However, if it wasn’t for the fact that I have more sawmill slabs than I could ever burn, I might lean towards the direct burn method like Gary and others use, since it is probably more wood efficient.

I now have enough charcoal to move on to crushing, screening, and building the gasifier for a test.