I upgraded my firebrick with a tungsten carbide nozzle, (a size 5 wedding ring) and I also mounted a thermocouple inside the reactor to gauge the reaction temp. The ring has curved sides, so it fit perfectly into the 3/4 hole. I cemented it in with a little furnace cement.

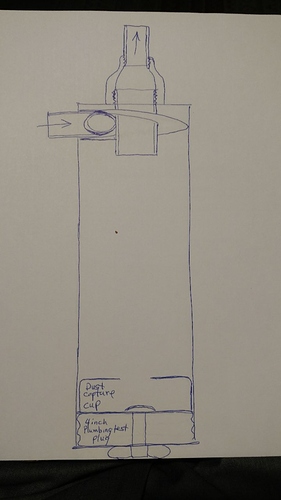

When I opened the reactor today the lid had a considerable amount of moisture condensed on it, so hopefully the brick has been more or less dried out now. I am keeping my charcoal in a sealed bucket, but I suspect I am going to have a hard time keeping it completely dry in this climate. I looked inside my filter and did not see any dust or soot in my batting, so that feels hopeful.

I also tore down the blower I had built, and added 4 more vanes to the rotor.

This appears to have increased the suction by quite a bit, so I think this setup is actually going to work. The gearbox leaks oil like a seive, but since it will get so little use and at such low RPMs I am not too concerned. I painted the parts, because now that I have put so much time into it, I might as well make it last. Once the paint has cured I am going to seal all the parts when I re-assemble it, as I am more than a little bit paranoid about CO leaks.

I redesigned the manifold for the gas intake, and will mount it to the generator frame to take some stress off the engines intake tube.

My goal is to try and make a system that will be fairly easy to adapt to any engine, as the one I have is going to be really hard to implement a governor on (since it has no carb). My thinking on the manifold is:

Red valve is the throttle,

Blue controls air intake,

Ball valve goes to the blower - I brazed a short threaded section on to my blower housing, so it will mount directly to the manifold.

Opposite the throttle will be the gas intake from the reactor.

I do have a quick question about alternators - and that is can they be spun up with no load? Could the regulator be damaged if the RPMs get too high and create a higher voltage than it is rated to handle? @SteveUnruh : you are a bit of an alternator expert, are you not? Any thoughts?