That is very unfortunate.

I hope you will document the rebuild as you did with the build, it would be interesting to see the changes that you are planning, I want to build something to make charcoal in after the gasifier is done. I have some tanks lying around waiting to be used.

Yes, and bad weather. Mud everywhere. Almost one month missing income now… about 30 14kg sacks behind order…

If any of you historical wizards have any pictures of old style charcoal kiln pictures l wuld apreciate them a lot. Maybee get some fresh ideas.

Did i hear someone calling for a history nerd? ![]()

If you want to go historic, pros: gives very good bbq charcoal, not much equipment needed.

Cons: you have to watch over it like a baby, a week.

This is basically the same, only a masonry “house” stuffed with wood, with 4-6 air dampers in floor level.

This is what i based my builds on, the “carbooven” pros: can be build from iron scrap/tanks. All tars, turpentine, wood vinegar is collected, and the un-condensable gasses is fed back for heating.

Cons: if it’s built solid, not practical to unload.

Edit: the text says the center flue is of no practical use, and should be omitted.

More modern style, can run continous thanks to “B” charcoal collector/cooler, each batch dumps into this to cool down when next run.

Also collects usable tars and stuff.

If you want to go all in, cart oven, a “train” of carts slowly moving upwards charring.

Hope you don’t mind i post this here also, if it can give you (or anyone) some ideas.

Don’t say this is a good construction, but it works.

My pivoting charcoal retort, made from a original Imbert gasifier that was to rusty to save.

It was meant to be a super-simple build, but i went away.

Built on a small trailer chassis so im able to move it.

The big pipe directs the pyrolyzis gas down to the “drop-box” where some low-grade tar can be collected, my intention was to water-jacket the pipe to get more condensation.

Lid and pyrolyzis gas outlets, it got four “chimneys” to spread the heat evenly.

Hand winch for tilting/emptying, bicycle wheel act as a pulley for the cable.

Principal drawing.

Pros: easy to empty, with dry wood the need to maintain the fire is about 45mins, before it “runs by itself” on pyrolyzis gas.

Cons: heat really goes hard on the metal, limited life.

Last winter I lost most of a 55 gallon drum of charcoal the same way. I had already sifted the ash out from a load from my wood stove and didn’t see any thing glowing so I dumped the char in the barrel. Next time I opened it it was burned down to nothing.

Thanks for the input guys.

The thing is, most of my customers preffer my charcoal over the classicaly baked one (in a kolmila, is that the right Swedish word?). It has less volitiles, less smoke and smoky flavour (some dont like that) and doesent burst flames. Also its not quenched so much less moisture, quick start.

If that wuldnt be the case l wuld probably make one of two huge heaps per year and be done with it.

And the smoke is a problem too. Im at the top of a valey. I time the cook so that the smoky phase is during the day and wind blows upwards. In the evening all the smoke starts blowing down the valey like a river and flows to the village about 2km away.

Hi Kristijan,

i have been thinking more about your idea to make a kind of refinery, to collect tar, vinegar, methanol… Do you have more thoughts?

Rindert

I saw this style to collect the vaporized tar and wood vinegar

They just cooled it with a flow of water but I am thinking to lead it through a bigger tank like a 500l (130 gallon) water heater filled with water and by the time it heats up there are no more vapours to harvest (I haven’t done the math but if it isn’t enough with 500l then perhaps two in series with eachother) and then feed back to the kiln for re-burning.

This I would do with dampers so I could choose if I would like to harvest or not.

Just an idea thrown out, have not really thought it through so there might be obstacles so it wouldn’t work.

a closed retort like that would work for plastics to gas as well with a little better cooling system.

I can’t find a reference to a battery of them that made coke from wood. It was like in Kentucky. But this is the beehive coke furnace. You just need a hill, a few rocks, stone tools, a Tone that knows how to use them and a shovel to backfill it. ![]()

About cooling of the gasses i’ve post somewhere else my turpentine collector for my tar kiln, works pretty good, but needs lot of cooling water.

As for making coke i believe they used coal as raw material?

Here is a coal-mound, like the charcoal stacks, these was an enormous waste of energy, only for getting coke for iron melting.

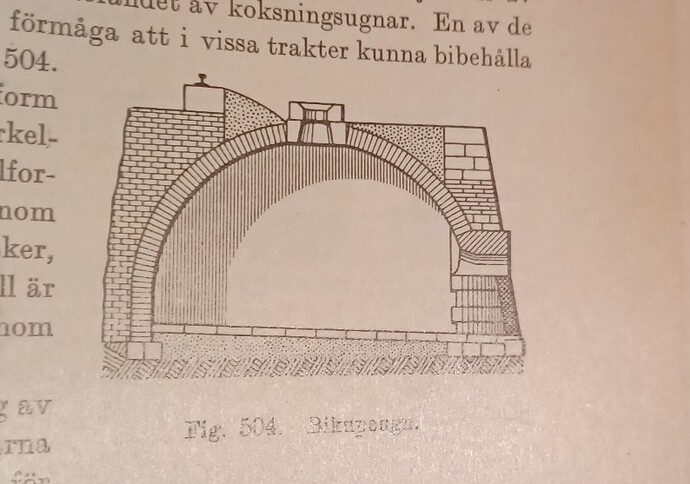

Here is a bee-hive kiln for coal, these was fired up with wood until the innards was glowing red, then filled up with coal to drive the gasses of.

You can also use coked charcoal for the steel process.

That is a beehive style, apparently there is no consensus on the name for the modification. These guys call them belgium coke ovens.

https://ohiodnr.gov/go-and-do/plan-a-visit/find-a-property/belgian-coke-oven-ruins

The ones I was thinking of look like an old fashioned cone shaped beehive made of rope like these

Youtube Ai put this up for me. The kiln reminded me of Kristijan’s kiln.

How are your kiln plans coming along Kristijan, have you decided on a design?