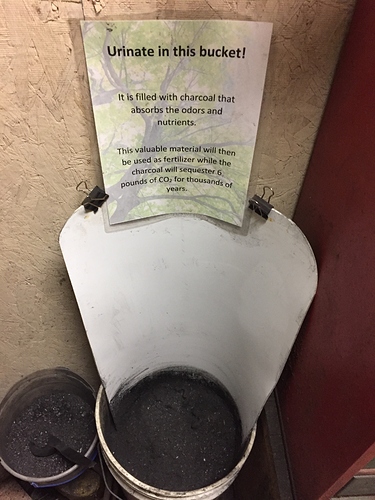

Thanks for posting that paper Henry, My shop is equipped with a crapper and urinal which both use charcoal. I’ll never go back to using an out house knowing how well charcoal controls the odor. Keep the crapper inside.

Gary in PA

Well I’m nutz so I feel justified in saying whatever I like. I think people take shit too seriously. Human, dog, I put it all in my compost pile. I get my philosophy from The Band. " Careful where you step, watch what you eat, sleep with the light and you got it beat" 73 years old and my only pharmaceutical purchase was an Anti-biotic for a strephed throat in 1983. Took two days of that.

Local Mansfield lumber store has 55g barrels

for 24.99 plus 3.00 dollars for the lid. Get 2 next month, they have about 20 out back.

Lived in a POS.single wide moble home for 19 months had to process pond water for the last 5.5 months. I filtered, boiled, and filtered again before using the water. Best water I ever drank!! My son’s did not understand why we could not just filter. Until I explained the virus threat. This was a farm pond that got a lot of field run off when it rained. A Berkey charcoal type filter can remove 99.99 percent of contaminants. But you cannot filter out a virus.

That pond had some ducks living there that spring. Wasn’t taking any chances!

Jesse

Wise man.

A goona’be wiseman is one lived long enough to achieve this.

S.U.

I have a suction well inside a stone lined dug well , and I worry about it all the time . I had water tested for 'certificate of portability ’ and did not get it . I think it was some procedural problem where I did not ask for certificate in a manor they would respond to . I just had water test done where "certification of Portability " was mentioned . I did not get certificate and thus did not get organic certification and quit farming . The water test said that my water was safe , I bought an ultraviolet filter and was going to retest , domestic issue occurred , ultraviolet filter failed in a few hours , I have a sediment filter . I changed it after a year . Now it leaks and I get a bucket to flush the toilet every day .

I hear a lot about UV filter units failing early, sort of like cheap inverters and fluorescent light ballasts. I wonder if there isn’t some component common to all three that is responsible. I did a little digging to see if it isn’t cheap capacitors or something that would be an easy fix but that’s not what I found.

The site has some things to try for trouble shooting: UV Light Disinfectant System Repair How to troubleshoot & fix problems with a UV treatment system

UV treatment, when it is working, is a great alternative to boiling. But it sure seems finicky (and expensive) for what amounts to a fancy light fixture.

Just came across this good explanation of different types of pyrolysis and torrefaction. Wanted to capture it for the DOW community:

Zagazig University

Pyrolysis is the decomposition of biomass in the absence of oxidizing agents. Usually at around 300-650⁰C and reach more than this temperature for some biomass materials.

Torrefaction is similar to Pyrolysis but occurs at lower temperature (around 200-320 ⁰C)

Both techniques utilize the decomposition of biomass to produce valuable products such as: Coke, Syngas, PVC, charcoal and lighter hydrocarbons like gasoline.

In the Pyrolysis Process, the body of biomass is heated to the pyrolysis temperature and held at the temperature for a specified time. The biomass degrades into 3 constituent yields: 1) Solid Yield – Char or Carbon 2) Liquid Yield – Tar, Heavy Hydrocarbons and Water 3) Gas Yield – CO2, H20, CO, C2H2, C2H4, C2H6, C6H6,etc. There are diffrenet types of pyrolysis as:

Slow Pyrolysis: Primarily to produce Char through Carbonization. - Utilizes low temperatures around 400 ⁰C over a long period of time to maximize char formation

Rapid/Fast Pyrolysis : Primarily to produce Bio-Oil and Gas -Biomass is very rapidly heated (~1000-10,000 ⁰C/s) to a temperature around 650⁰C-1,000⁰C depending if bio-oil or gas products are desired. Product gases are quickly removed and quenched.

Paramters affect on the pyrolysis process:

Heating Rate: -Rapid heating to a moderate temperature (400-600⁰C) will produce higher volatiles and increased oil production. -For example if Esperanto (a grass) is heated at 5⁰C/min to a temperature of 400-500⁰C a typical liquid yield is 45% of the total mass. If 250⁰C/min the liquid yield increases to 68.5%.

Pyrolysis Temperature/Residence Time: Char formation will decrease with increasing temperature. -Complex relation between the individual products and the residence time and temperature

Biomass Type: -Major constituents of Biomass are: Cellulose, Hemi-cellulose and Lignin. -Cellulose (150-350⁰C) turns into condensable vapour (tar) -Hemi-cellulose (275-350⁰C) yields primarily non-condensable vapour -Lignin (250-500⁰C) degrades slowly into char and liquid yield Additional Factors such as: Pressure Ambient Gas Composition Presence of Mineral Catalysts

Important Factors governing the molecular reactions are: Chemical Kinetics, Heat Transfer and Mass Transfer. -Physical aspects of the molecular reactions: 1-Three Stages of Pyrolysis 2-Up to 100⁰C the particle‟s dry out. 3- At 200-600⁰C molecules of biomass decompose into solid and liquid yield along with non-condensable gases. (TPrimary Pyrolysis)

Vapours are extracted and condense as tar or bio-oil, while large molecules continue to crack yielding char at 300-800⁰C. (Secondary Pyrolysis).

Fine particle sizes offer little resistance to the escape of condensable gases and will therefore lead to a higher liquid yield. Whereas larger particle sizes will provide more resistance to the vapours as they try to escape and will therefore provide more opportunities for the vapours to crack resulting in a higher char yield. (Pyrolysis Kinetics)

Chemical Aspects: The biomass composition (ie relative levels of Cellulose, Hemicellulose and Lignin) effects the final pyrolysis products. There are several models of the reaction processes that describe the interplay of factors like pyrolysis temperature, residence time and heating rate.

1-Kinetic Models of Pyrolysis, 2- One-Stage global, single reaction models ○ The pyrolysis is modeled by a one step reaction using experimentally determined factors, 3- One-Stage, Multi-reaction models: ○ Several parallel reactions describe the degradation of biomass into the various yields. 4-Two-stage semi-global models: ○ Includes primary and secondary reactions to provide the most detailed results.

During the Pyrolysis process heat is Transferred to the particles primarily through radiation and convection, though some heating techniques use conduction. The primary heat transfer mechanisms are suggested: - Conduction inside the particle - Convection inside the particle pores - Convection and radiation from the particle’s surface. Heat transfer considerations are especially important in the design of the pryolyzer as heating rate plays a large role in the determination of the final products. All pyrolyzers will heat up the heating medium before operation though the medium‟s vary - Reactor wall (Ablative Reactor) - Gas (Entrained bed reactor) - Heat Carrier Solids (Such as those in a fluidized bed). Though most units require heat initially, once the required temperature is reached several exothermic reactions proceed that provide enough heat for the process (Autothermal Reaction).

Though early pyrolyzers (the beehive ovens) were designed to maximize the production of char, modern units are designed to produce either liquid or gas. Based on the type of products that are desired the designer will select the required heating rates, temperatures and duration of the reaction. Once the previous points are determined an appropriate reactor is selected.

Reactor Types 1-Fixed Bed 2- Bubbling Bed 3- Circulating Fluidized Bed 4-Entrained Bed 5- Others. Fluidized beds will provide the fastest heating rates while fixed or moving beds will be slower

Torrefaction is a milder form of pyrolysis carried out at temperatures around 200-300⁰C. It is primarily used as a pre-treatment of biomass to improve its energy density through drying. During Torrefaction the biomass dries and partially de-volatilizes in such a manner that there is a significant reduction in the Biomass’s weight while the energy content is maintained. Biomass darkens and becomes brittle (through the decomposition of the Hemicellulose molecules of the biomass). ○ Because Torrefaction makes the biomass brittle and easy to mill it reduces the handling costs. Basically it will allow a strong fibrous material to become brittle like coal so that it may be pulverized for use in a boiler or other reactor. Drops weight of Biomass to 62%-69% of the original mass, though the energy density can increase by 29%-33% . Torrefaction will alter the Biomass such that it will absorb less moisture while stored then regular Biomass. Advantages: 1-Offers cleaner burning fuel with low acid content in the smoke. 2- Absorbs less moisture when stored 3- A higher heating value may be achieved 4- Increases the ease of handling and allows for use in pulverized coal fire boilers

Wow. That’s impressive. I must be like one of them Idiot Savants. I just throw it in a barrel or drag it out of the wood stove. Have ground plenty of it down to a powder and it looks like char all the way through.

Today I had about twenty gallons in my dryer toasting it nice and crispy but, here’s the idiot part, I forgot about the snow on top of the barrel so when I lifted the lid all the melted water ran back into the barrel.

The gasifier is to run at 700 c and be run continuously and be shut down if temp reaches 900 c . I put in dry wood chips and there is residual of charcoal . I am not sure I have ever done this right .

Found this little gem today.

Demonstration of making biochar according to the recipe of Stane Vidmar. Wood chips work with the R8 wood chipper

https://www.youtube.com/watch?v=aGhkZ5fROFs&list=PL0IFfLlrqAsI8JPph4A47brVz6XZzoIdq&index=3

Ha, look, a fellow countrysman!

I would like to share some pictures of my retort. I primarily use it to produce charcoal for BBQ but when we sort it we get a fraction thats perfect for a gasifier.

I only use birch for making charcoal. The retort takes 3 cubic meters of wood. I get 200 kilograms charcoal for BBQ and about 15 kilograms for my simple fire gasifier.

I have just started exploring charcoal gasifiers but i think its very interesting and im reading everything about in this forum. So far im only running small engines in charcoal.

That’s an impressive retort. How does it work?

Its almost like a barrel in barrel retort. There is a fireplace underneath where you make a fire and heat the inner barrel up until it reaches about 300-350 degrees Celcius, then you can lead down the pyrolytic gases into the fireplace and the wood heats itself until its done. It takes about 12 hours to burn a batch of birch.

Hello Jorgen, this is so nice! Seems preety much exactly the same as myne. Only myne is a bit smaller. And l have 4 chimneys instead of 3

Burning as l type!

Yes Kristijan its pretty much the same. Ive only got two chimneys, and two gaspipes for flaring of so the retort doesnt get too hot. Im afraid it would melt.

Ha, myne did. Several times  l estimated the fireplace to last for 10 runs, its pushing 30 and still no holes. Althugh it looks like its made of playdooh

l estimated the fireplace to last for 10 runs, its pushing 30 and still no holes. Althugh it looks like its made of playdooh

I know what you mean Kristijan. My first retort is waiting for a reconstruction, it didnt hold up for the heat more than 30-40 burns. That one is about the same size as your retort.