Great, then my calculations was close enough

Done with my night shift week now so I hope to get some building done to morrow.

Well, calculators are OK here, the ones typeing are faulty sometimey

Theory is only the base of practise, a guidence. Imbert calculations offer great starting point and are a cure to many headackes, but can still be altered to need.

“It seems anything will work in a gasifier, except tight measurments and tolerances”

J-O. Ollson

one of my favourite gasifier related quotes

Anyways, you will be fine with your plan.

Roger; I want to apologize for my first reply to this particular post. I am 80 yr. old and my memory is not so good. I had forgotten what a great introduction you gave to us in your first post about how far you had already come. I think from now on I will concede to the younger members of this group. TomC

Tom I am new to gasification and Im glad for all the help I can get, I have learned over time that its in the details one should turn to the seniors.Its always that one thing you have never experienced youre self that is going to help you.

Mr Tom,

I hope this doesn´t mean you decided stop posting. I wouldn´t like that. You´re one of my favorite posters. You have a very unique ability to dress your thoughts in words and your posts are always fun to read.

Thank you very much for that, JO. I hope it doesn’t come to where I have to stop posting, but for now I have to be more aware of what has been posted in a thread, before I jump in. Right now I am trying to relate the formulae in FAO72 with the formulae of Kristijan’s post. I suspect before I am done I will be asking a lot of question of other members for clarification.TomC

Good!  +20 characters

+20 characters

That sounds like me Tom, I read a post. By the time I get done writing it, and correcting what I have written, It has been answered already and with a better reply then mine. Oh well at least I trying to help.

I agree very much with JO.

Bob

I value everybody’s input.

i like the likes i can give… even its only one per time…

https://www.reset-energy.com/en/syngasmart-chp-technology/#cosasy

This design has three pyrolizers and two gen-sets so you can repair one while other is in operation .

I think that is good idea . not sure they actually sell better system then you will build

Hi Henry, they have a lot of the same ideas that I have, I how ever am going to dry my biomass on the roof with a double floor system from the waste heat made inside the container.

Here is a picture of my feed screw.

As of now I have two B20 volvo engines to be used in the container, I plan on two more in storage since these engines are so cheap to buy and easy to repair.

Im going to start with one gasifier in the beginning since its not set in stone the best design for continuously gasification.

I plan on two belt driven generators to get a even load on the bearings and redundancy, I know its more energy efficient to use direct drive but I need to be able to change gear ratio,

Most of the motors around here are 1450 rpm or 2200 rpm, some times you can find 1850 rpm motors but to find with the right voltage and all belt drive would make it more versatile for my use, also safety vise you would just burn up a belt rather than a coupling.

I do not have a working system . I do have one building for making and storing wood chips . I use a space on the floor of a separate barn to sift and size wood chips . I have a large area of concrete slab part of which I painted black that I use to dry wood chips . The generator pryrolizer and wood boiler are in a tractor shed . the inverter and batteries are in the meat locker . Having everything in one space and automated will eventually lead to devastating fire . I think automated feed systems will eventually lead to devastating fire . this has occurred I do not have good reference . usually it happens at places where people are working but not living .

Hi Henry, I understand the concern for safety when it comes to fuel and all, how ever when you drive your car at 60mph with 20 gallon of petrol product behind your back or a 100kWh of lithium 2 inch from you’re ass and all variables of people you dont know down the freeway…

Hehe joke aside, Im running a steel container standalone from my buildings, if it burns down all I lose is whats inside.

The reason for this compact setup is to get it as efficient as I can, easy to swap out motors and so on, I can use raw wood chips with no pre drying, in the long run I would still do a compact setup in a fireproof room inside the barn, the wood chips would be outside and screw feed inside.

Has anyone built a header heat exchanger here on the forum?

That may however cause trouble. Gasifiers don’t like moisture. “Dry” fuel contains enough moisture as is. A condensing hopper where the chips are allowed to stay long enough to dry out will be required. I’d suggest you plan on using as much heat as possible from the outgoing gas and engine exhaust in the drying process. It will ad a great deal of complexity to the build, but that’s ok since you’re stationary.

Yes that is the plan Jan-Ola, I hope that logs that has been stacked over the winter is going to dry enough.

The drying process after the half dry wood chips is loaded on the roof is as following: the roof has a double perforated floor for induced air to dry the wood before the feed screw, in the loading pipe and the hopper Ill use the wood gas to pre dry.

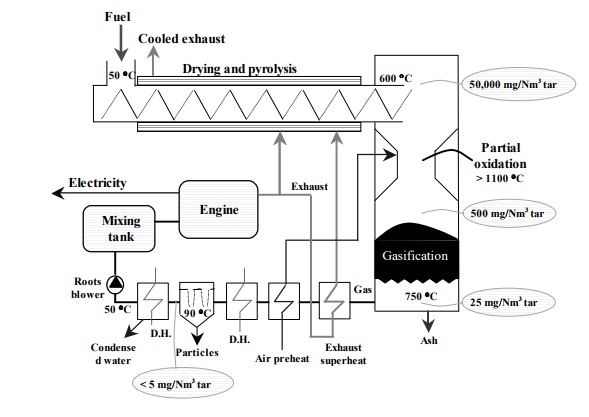

I have been studying the Viking gasifier and Im going to use ideas from that plant.

Yup, preheat the fuel as much as possible is the way to go…

At 600ºC you’ll have only charcoal left… hence the clean gas…

Hi, Roger!

23.2017

Drying and even pyrolysing, but nowhere is that extra moisture taken out before the real gasification…? Why? Steaming through is an extra burden for the process.

It will carry heat through the hearth to no wail. Just for recycling?

Happy Christmas!

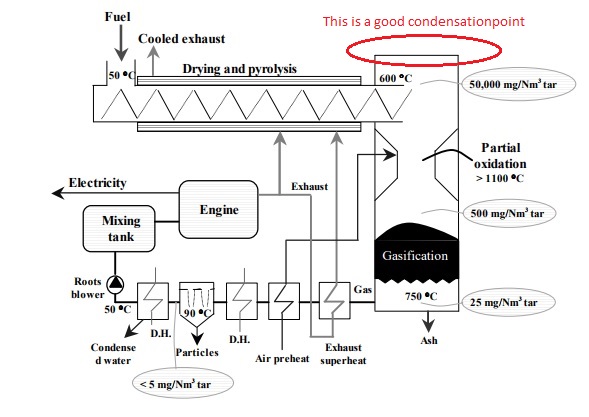

Hi Max, hopefully the predrying of the wood chips will make the humidity of the chips under 30% before entering the feeding screw, after that my plan is to condensate some of the rest of the humidity at the top of the hopper on a cooled surface and out to drain tank.

http://task32.ieabioenergy.com/wp-content/uploads/2017/03/04-Weiss-Gasification.pdf