Don,

This is helpful. Can you say some more about your water drip. Do you increase the amount of water as the load goes up? How do you determine the optimum water flow? Does your setup just let excess water drain out when idling? Do I remember right that you do not use EGR? When do you start your water drip?

Bruce,

I start the water drip when I start out driving. The dripper knob is in the cab so I can see the rate of drip through the glass but I don’t adjust it beyond the 2 drips per second unless the temperature in the steam chamber comes up over 250 degrees F under fast driving conditions. It usually runs 200 to 220 F. Friday when it overheated it was 630 degrees F. The way my steam outlets are located at the nozzle, I never thought I needed EGR. I do use EGR in my lawn tractor though mainly to cool the reaction to save the nozzle.

You have started something. I see another “Tracker” posting. I didn’t know you had hybrid capabilities. What are you using---- rheostat or PWM? I didn’t have any luck with a rheostat. TomC

Tom, I use a headlight switch like Wayne but usually either full on or full off unless it needs just a nudge; then I switch it to 3 or 4 volts for a second or two or three. It seems that when I turn it on and back off that there is a “die down time” where the pump line still delivers diminishing pressure for a couple of seconds and that usually gets me to a point where I don’t need Gus O’Lean to help push.

Don,

This is very helpful info. It has been observed that higher reaction temps can produce gas with a higher % of CO. I am assuming that you were running at a higher reaction temp but had less power than a lower reaction temp with water. Since Kristijan quit water drip in favor of higher reaction temps, I wonder what he has to say about this? What temperature does your steam chamber reach during startup, or long idling or flare without water drip? Will the dry steam chamber overheat only when the engine is under load and sucking more air?

Bruce, I have two thermocouples in the reactor, one in what I call the steam chamber under the cast iron rotor and the other above the nozzle and off to the side for a “relative” reaction temperature reading. When I said overheat I really meant higher than normal running temps in the steam chamber. The relative reaction temps were pretty close to normal in the reaction area above the nozzle. Both probes show ambient at startup and both climb at nearly the same rate in the beginning until a flare sustains at about 350 to 400 F. Then I quit flaring, turn the drip on, start the engine and drive. When I shut down, and turn the drip off, then the temps in the steam chamber rise to 600+ degrees in a short time and then gradually go back down. I don;t know if this answers your questions. but I am still learning this process too. I should note that all my trips so far have been at 30 minutes or less one way so I do not have long run time information yet.

Hi Don,

Yes it does make a huge difference…

1: it does improve your flamespeed

2: it gives more HP and more control in your reduction zone

3: it does reduce the amount of fuel needed but more important:

4: it reduces the emissions on your tailpipe…

5: it put an enormous smile on your face…

Yes, thanks, that gives me some more info. So we don’t have a power comparison between water drip and a higher temp reaction zone since your reaction zone temp stayed the same without water drip. I wonder if this stable reaction temp is because of your nozzle’s large size?

I’m thinking of using a 12 volt pump and PWM to increase water supply as load increases.

The only reason l stoped useain a water drip was the simplitity. There were 2 main reasons. It gets cold in the winter here and if one wuld want to make things run perfectly ( produce constant CO/H2 ratio) for easy driveing and good fuel economy the things get complicated and expensive. With a waterdrip there realy wasnt much diference in power between gasoline and chargas. The power diference is huge while useing water or no. But as l have sayd before; my Seat needs to drive me 20 km to my job everyday and 20km back at a speed no higher thain ~60-80 kmh becouse of threfic so l dont need much power anyway.

So l made a compromis: less power for more simplitity. But if one wuld have diferent needs l say use as much water as posible!

Don, I’m really pleased to hear you’re doing actual work driving in the tracker. To me, that makes it so much more worthwhile.

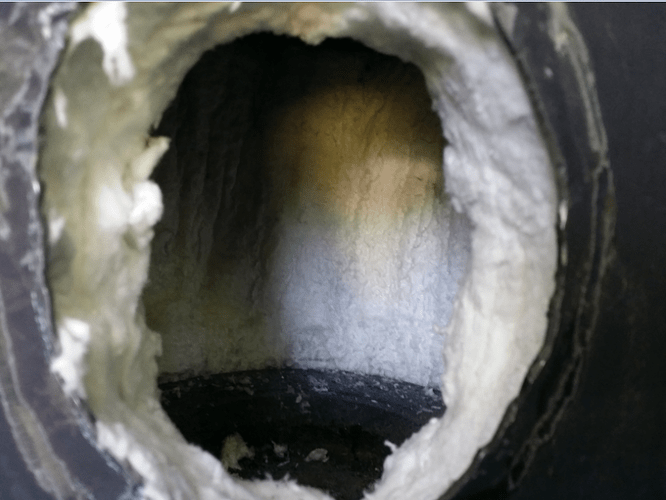

I decided to build a clean out near the bottom of the gasifier so I can clean clinkers out from time to time. After emptying the unit out I took this picture of the nozzle with 157 miles on it. It still looks very good.

This 4 inch pipe coupling with a brass clean out plug cut on an angle will be welded on and I am hoping to be able to find clinkers by feel and remove them without emptying the charcoal.

I also plan on insulating the bottom 10 inches of the reactor with 2 inch thick ceramic blanket to make the shell cooler and keep the heat where I want it.

The 4" pipe should give you a good size opening to “fish” through. ( have you ever gone ice fishing?) TomC

Are you gonna be able to fit them big ole paws of yours through there? I remember shaking your hand!

Ahhhh, the brass clean out plug. I’ve chiseled 1000’s of those off sewer lines to gain access for unplugging drains.

It appears you have a recessed plug. Is there a reason for that? I know time makes it hard to get these off, I’m not sure sure how heat will affect this. If ever it is difficultand you want a different plug, there is a 4 lug plug you can just use a long chisel and as much leverage you need to pry between the lugs to remove it. But then again, the plumbers never applied anything on the threads for easy removal.

Bill, One side is recessed; the other side is raised. I’m thinking to use the recessed side and make a wrench for it. I believe it will be less apt to break that way.

Jim, Yeah I can get my hand in there-JUST. I would have liked a 5 or 6 inch but this is what I had on hand. - you ought to know all about that

That’s part of what all this is about - “savings” finally paying off. It is to me anyway.

I installed the ceramic blanket and welded the cleanout on this afternoon.

After filling with charcoal I lit her up just to see if it made a difference and I think it does. It heated up a little faster and made gas a little quicker. I shut her after running the engine for maybe 4 or 5 minutes. Tomorrow I will give it a better test.

Don, how did you hold it in place? I am going to put it inside my gasifier housing in side the barrow. The clean out looks great. Good job on it all.

Bob

:[quote=“Bobmac, post:138, topic:2439”]

how did you hold it in place?

[/quote]

cut it a little long and force it in