Matt turned me onto “purple power” at Argos last year.

I will second his opinion that it is the best tar remover I have found.

So my fabric came in yesterday, so now to figure out how to sew the seams to make a filter bag out of it. I think most thread will deteriorate in this environment and even fishing line will most likely become brittle. Then I had thought why not staple it!! So thats how I will proceed, just ordered a heavy duty packaging stapler.

Hi, Bob!

Don´t blame me; that is a Swedish self-clogging horizontal bucket!

(the one of november 2016)

Max

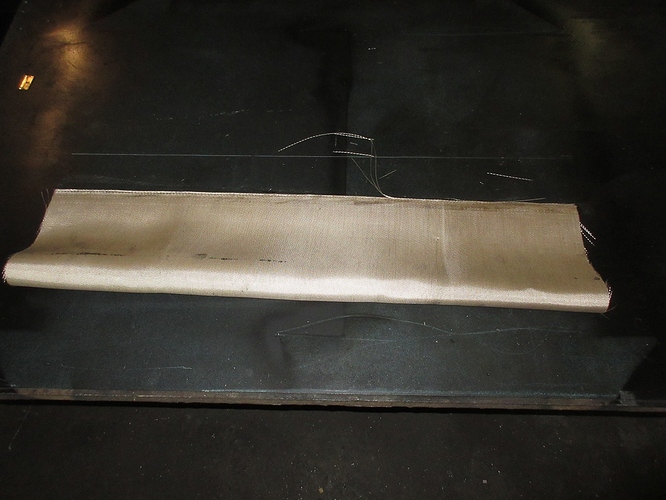

I snapped a couple of pics of the cloth as someone was asking about the permeability of it.

It is very tight woven material so this I think is going to filter at the micron level. This is why Im adding a self wash system. Since I can control the wash pump with controls, Im going to run with a timer. So a few seconds on and then off for couple of minutes. This should keep the foaming issue down. I plan to use a spray nozzle to help coat the entire bag from inside.

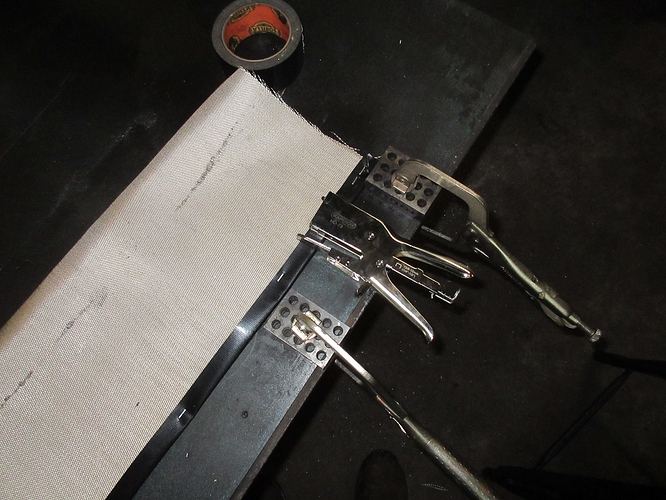

So my stapler came in today and went straight to working making a bag filter today. It took me maybe 30 minutes to construct this. This is a 5" OD bag and is about 34" in length. After construction I blasted it with the AmTech blower on full blast and it had no problem at all breathing thru it. I was worries the fabric would be too dense but it is probably about perfect. As it filters and accumulates it will filter even better and with pulsing solvent through it will help it become less passive.

Matt,

You can get high temp thread should you decide to do some sewing. I most recently tried wrapping high temp felt around a cylinder made of two cake pans separated with about 10 inches of 1-inch mesh hardware cloth. The felt is tied around the cake pans at the top and bottom. I like this no-sew design and it seems to be adequately secure. I think someone described a similar set-up on the “What Kind of Media?” thread.

Steve

What are the corrosion properties?

Here is the pump and spray nozzle. The pump is a 3 gpm pump. These are very good pumps Ive used a number of these on machines over the years for coolant pumps and things like this. I have not tested yet but should be close, If not Ill just get a smaller nozzle. Its way more passive than I thought it would be.

Matt, I have no idea. Sorry.

Yeah thats thing, this cloth is the only cloth I know of that will with stand the corrosion. Wood gas will deteriorate most other clothes in a heart beat. This cloth is more known for its temperature capability but this is not reason Im using it as it has a very high resistance to corrosion and chemicals.

Matt,

I bought thread for the Meta-Aramid felt and thought that possibly thread might be available of the material you are using. The nice thing about the wrap-around approach is that no thread or similar fastener is needed.

Yeah I was going to have my buddy sew this for me. He is a professional Upholsterer and does a lot of leather marine upholstery work and he said stapling would be the better option. Although it was my idea first as we were brain storming this. haha.

Can you give me link to the felt? As you need a container for the edge of fabric so it dont fray. Im using Gorilla tape for now, but I dont think it will hold up.

Never mind McMaster Carr has it. I just ordered another 36 x 36 sheet of the fabric along with 2" wide .125 thick felt. Ill use the contact cement to aid in assembly and a staple away. That stapler is awesome. Be nice If I could find SS staples that fit it.

Edit:: Well what do you know, McMaster Carr has them too. My brand of stapler is not mentioned but it looks like they will fit.

My felt came in today, interesting it is bit more passive and would also make a great filter media.

McMaster also offers felt specific filter media that can with stand 300*F that is chemical resistant. It is probably the same stuff used on the CNC machine filters I used to build. If so that felt was very tough stuff.

300f should be plenty sufficient for my systems the gas is generally bellow 200F after leaving the cooler. This felt could be good for a coarse filter stage and then the silica cloth in the second filter tower as the fine filter.

Matt,

Seems that McMaster-Carr is a great source for high temp flexible material. You may have mentioned them in another thread as a source for gasket material.

The felt came in today. Yes this is the stuff Ive used before. It is fairly easy to cut with scissors when dry but I know from past experience when this stuff is wet it will dull a utility knife in a heart beat.

I got the 100 micron felt and it is about three time more passive than the Silica cloth. I did some test as Im a smoker and blew cigarette smoke thru it with and with out Purple Power treatment. As suspected it did clean out the tar from the smoke, however with the purple power it carried it out of the fabric. That is what I wanted to see; however, it did out fine foam to the other side. Pulsing the pump should keep this down and the twin cyclones I know from the past will knock this foam out. This duel bag filter should make clean gas comes out 110% tar issues are solved for ever and ever.  lol

lol

Matt- your recent post about the 100 micron felt reminds me of the 50 micron and 100 micron filters we used for maple sap processing.

Heres where we used to buy all of our supplies:

https://www.rothsugarbush.com/product-category/supply-store/filterings/filters-accessories/

Particularly the “Cone pre-filter” and “Orlon Bag” for 50 micron.

Also the “Sap Filter Bag”, which, IIRC is the 100 micron bag we used.

We called the “cone pre-filters” "paper filters and, although they were sold as disposable, we were able to wash them several times. We also washed the Orlon bags, too, of course.

I don’t know how these things might work for tar, but even cold sap runs right through the 100 micron material.

These materials work at least up to 190° F.

Pete Stanaitis

Nice, I bought this felt 36" x 72" for just over $26 bucks shipped. So very cheap and using the staple process they are very easy to make.

I can make four filter bags out this material. So about $6.50 plus staples pr bag. I think with the cleaning solution they should last a long time. Ill know more once I get a machine built and running

Felt works great in my experiances but it will collect trace amounts of tar over time and saturate in a hard shell, together with ash and soot. At that point it becomes useless and imposible to clean. Its a good safety thugh…

Yup this is why Im using a pump to spay in the solvent to keep it clean. The pump will run 5 to 10 seconds every minute or so. Just enough to saturate the media with the cleaner to break down the soots and tars as they are produced; so it should not accumulate. This solvent works very well on fresh tar as they are produced.