Mart, If you happen to have a router speed control to slow the Kirby down a little, that would be good. I found that too much velocity and pressure can blow the soap solution away from the leak without forming a visible bubble.

OK, finally I uploaded my videos on youtube. Its an over view of our sistem. I have some pictures of details I´ll try to upload ( I´m learning).

These are the links:

Hope it´s clear enough

Eager to see comments

These ar some photos of the whole system and some details:

We use it for the plants in the farm in the greenhouse and others. We activate it with liquid humus from compost en we feed it to the californian worms; when it is composed, we add the activaded biochar to the compost. I´ll post pictures of the crop result. The thing is that it´s a excelent char for both uses (biochar or gasifiers) and it very simple, no need to cool with water, it´s auto “shut off” and the char is not wet FULLY DRY! and ready to use. We simply lite it and leave over night. Hope you like it.

abnervalbuena, looks like you have made good progress. You might want to consider creating your own thread for your gasifier as you will get more feeback that way.

Mart

I just tested the tightness of my gasifier.

I find diagnose depression with smoke is visible enough

I light a beekeeping smoker, I start the fan.

If there is a leak, the smoke goes very visibly worm hole

Thierry

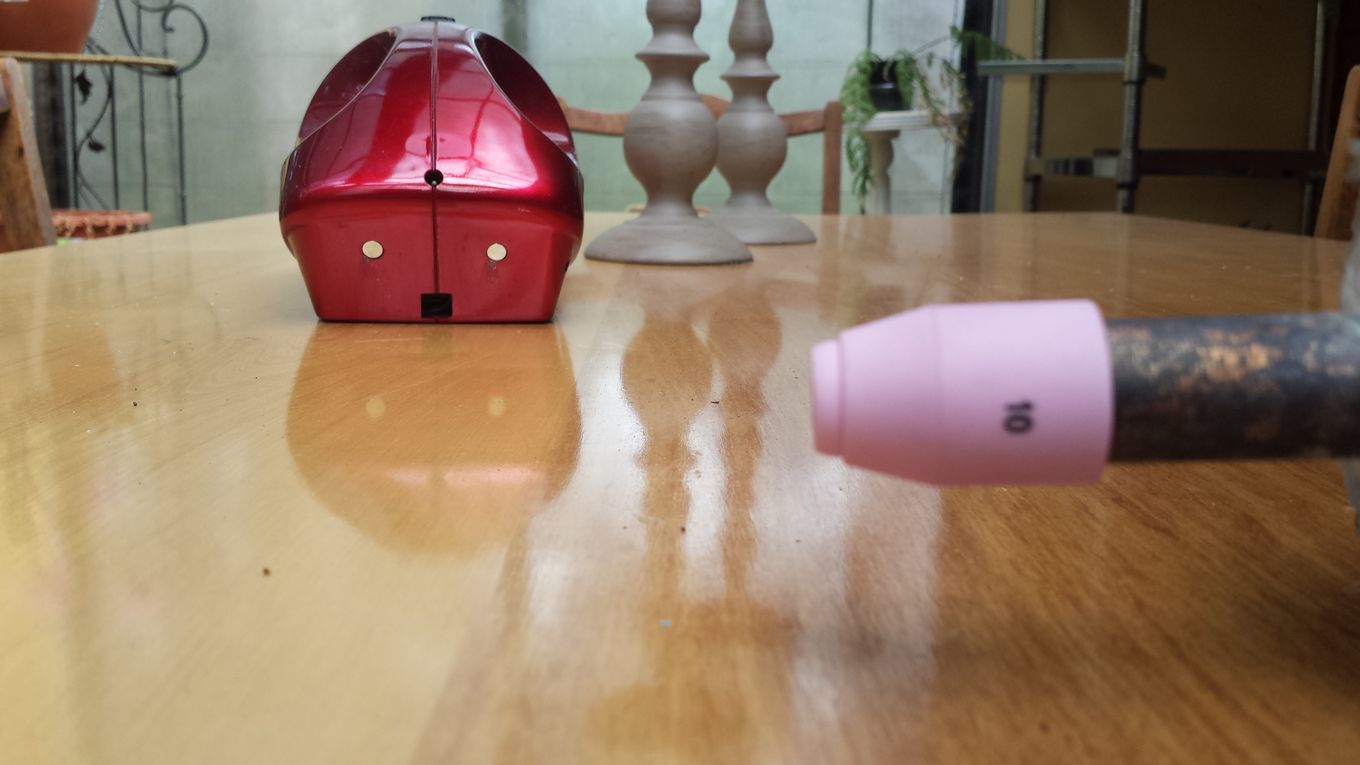

13N13 #10 TIG Alumina Nozzle Ceramic Cup Fit PTA SR DB WP-9 20 25 TIG Torch 10PK

So these have arrived, now my next question is how do I fit these in my 1 inch pipe? Or how does everyone else go from the pipe to these ceramic ? As I look at it I am thinking that is a huge restriction on the air flow coming in.

Hi Mart ,

Yes your correct the size cup you have there is pretty small , but Koen does says that the more restriction the hotter the char gets the better , I have used this size cup on my units and had ok results , but have moved onto the larger cup size now 1 inch hole and that seems to suit my tank better ,

Troy Martz said The cup threading is not NPT, it’s machine threading, so, all you need is an NPT-to-machine thread adapter , didn’t know that at the time of starting to use these cups and because I have no workshop at home I try and make things work best I can at the time , as luck has it I found some copper pipe that is a snug fit into the cup and also a good fit into the 3/4 pipe nipple( with a little filing out ) I had on my smaller gasifier . this is sort of what it looks like

I then placed the other end of copper pipe into threaded nipple

That 3/4 nipple screws onto a 1inch adapter and makes for a easy change .

If you have any gaps between the cup and pipe or pipe and nipple then pack it out with exhaust putty or glass rope , seemed to work and last pretty good for me . Those pictures by the way were just bits I had to hand to show you what I mean as the one I made is still inside gasifier

Cheers Dave

Mart, do you have threads in the inside of the ceramic nozzle? I was told those are machine threads.On my nozzle a 1/2 inch pipe nipple was close to the size of those threads but they were a touch too big so I ground the threads down and even though the threads were wrong, I could still get it to screw on. I cut cross slots in the end of the nipple to allow for expansion and shielded the whole works with a stainless sleeve. Kind of a redneck way to do it but it works. What size engine do you plan on running that you need a 1 inch air feed pipe?

Mart , I forgot this is the nozzle I now use on my 13hp and bigger engines they are so cheap, I don’t know how they do it for the price .

Dave

No threads  Looks like all part of the learning curve.

Looks like all part of the learning curve.

I like the looks of the “Collet” body on this set and they are threaded. I like the idea of having the heat away from the metal with the long tube.

The size of engine is this one →

Black Max 8125 Watt portable generator. GX 390 Honda 13.0

I am also considering running a push lawnmower with this setup, so I might be able to use the smaller nozzle size.

I am shocked the copper does not melt with your setup…

Yes Mart me too , its not a last forever type fix but it will get you many hours of run time .

What I have done for the last 3 nozzles I have used last year was to put the larger 1 inch nozzle into the centre of a tin can and rest same dia copper pipe on top of it just poking over the top of the can and then filling the tin with refractory cement , when set i cut the tin away and I just slide the pipe into my 1 inch pipe nipple inside the tank and away she goes for a couple of months , or longer if I use a water drip to protect the hot face .

Dave

Hi Mart ,

Just though I would try see how things are progressing with your build ,

Let us know if there is anything we can do to help move it along .

Dave

Progress so far. I am still working on the nozzle for the inner chamber not sure how I want to do the ceramic pipes inside… I am happy to go with the flat stock for input into the carb. Looks like I am not far away from my first fire I just need to do more thinking of how I want it done.

Hi Mart , yep sure looks like your almost ready to fire her up .

If I could just make a few suggestion’s now I have seen what your using might help a little , my first one was roughly the size of yours and on a small lawn mower engine would last an hour or more before the heat came through , so I am guessing it will take maybe 15 mins on your 13hp before it will be too hot .

It looks like you have 3 of the tig nozzles inserted into your pipe , if that’s how you are going to try it then you will have to make sure they are sealed in that pipe ,so the air will only get in through the nozzles and not in between them .

On the gas out I guess you will have that coming out from the lid from a 90 degree pipe fitting , if you can have a good length of steel pipe to help cool it before going into your plastic pipes and filter that will help , also don’t forget to run a bead of high temp silicone around the edge of the lid to make a good air tight fit .

And last but not least your charcoal will need to be as small as maybe your thumb nail to try and stop rat holes being created , any bigger and my guess is rat holes will make very short runs .

All the best Dave

I have made a custom nozzle for the inner burn chamber. I mixed vermiculite and sodium silicate and made this protection for the pipe.

I did a test run and I found that I could not get enough air in the system via the T coming out of the carb and into the engine. I changed the filter to popcorn with window screen and that did not seem to help much. The popcorn seemed to have moisture on it so that did not seem like a good idea.

I ran some temps on the char gasifier and it was 150 degree at the top, and 200 - 300 in the bottom of the outside of the chamber.

I am considering making a new pipe with no nozzles and using the sodium silcate and vermiculite for an outer shell. The one I had in the first firing looks to turn rock hard. I believe I am just not getting enough air flow to run the engine properly with the wood gas, but many variables too early to be sure what the root cause is.

That looks like TIG Nozzles RTV’s into a pipe. Is that correct?

Yes kyle. I thought I would take a long shot and see if the rtv would hold up if it was covered with sodium silicate and vermiculite. Results are not conclusive yet as I have not had the full airflow thru that is needed to run my engine, but looking promising ( so far )