New parts are starting to arrive.

This doggy bag of bits is from my nephew.

Things slow down this time of year,

Me too.

But I managed to get a new coat of paint on these old parts.

Tin work looks good, looks like this was all meant to be together.

Next I need some new gutty works inside this old engine.

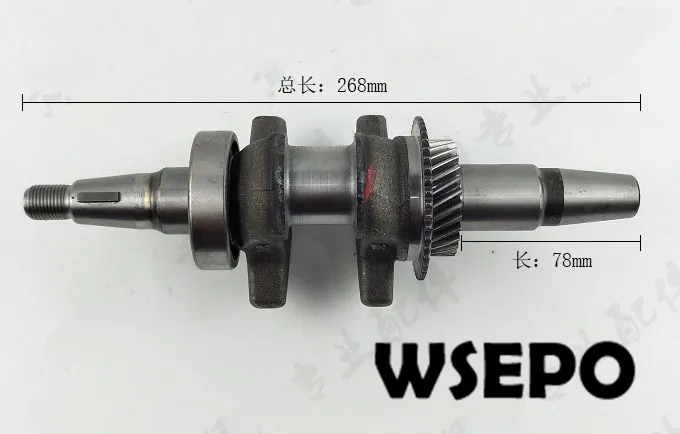

This is probably what I am going to buy and from whom I will buy it.

Then its back to mock up, remeasure and send the crank out for modification.

Looking at the old crank and the old generator has given me some ideas.

I could get the old crank cut and make a stub shaft for the generator and make a two bearing generator out of it.

Then I belt drive it off the GX390 future engine/project ) and run the 390 at 2600 rpm ( peak torque for this on gasoline ).

That should be just about the sweet spot for DOW…

People often ask why I paint everything with Red Glyptal ( or suitable generic product ).

Because it really covers well and stays on what you paint it with.

Its both flexible an excellent primer and a corrosion fighter.

A photo from work…

Back in the 1960s CCL was contracted to make this electrical equipment and the spec called for Red Glyptal inside and out

This paint is a little different from the modern version I am using ( old stuff probably red lead pigment ) but it stands the test of time in a corrosive and dirty environment

A well trained eye will notice as built electrical code violations. ( I did not install this in 1966 )

How good are you ha ha…

Hmm. Hard to see in the pic - fuse boxes not intrinsically safe?

You should strap your cables within 12 inches of leaving a box.

The splitter to the left you see two 3/4 inch rigid steel conduits in excess of 3 meter tap rule.

You will never need to worry about tap rule in residential wiring.

But proper support and strapping are code requirements you should always be aware of.

Everything of this era has lead paint, asbestos insulation, and PCB fortified oil in it.

even in your home…

I switch back and forth from Metric to English screw myself up too not just others

Not 25 feet 3 meters = 10 feet.

You are not supposed to have a cable longer that 10 feet in length in a conduit or cable that goes from a tap in the splitter to the lug in the starter.

Some people play fast and lose with that rule and try and have a conduit that is ten feet of less under the tap rule.

Under this rule you do not need to use a larger cable…

if you exceed this then the conductor must be rated at 1/3 the total ampacity of the splitter.

Still in a holding patter. m

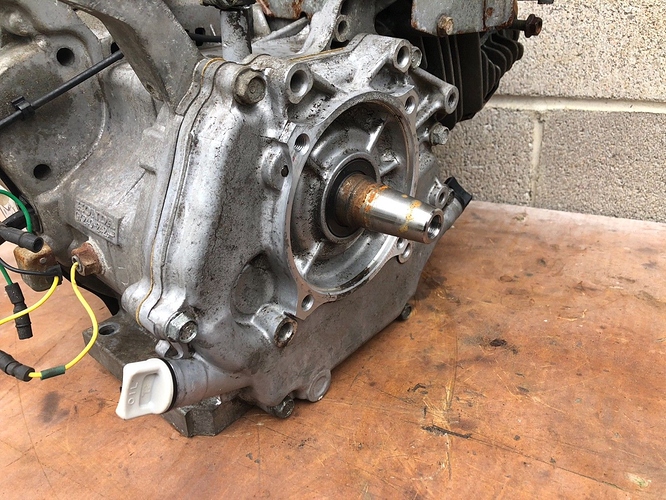

Observe my OEM crank

Now look at this and notice the difference in the governor drive gear.

They all seem to be made this way and no one will tell me if they can be interchanged.

I suspect they can but its hard to say.

And try and find this in the aftermarket in North America YIKES!

I am going all the way to China to source it.

Hey Mr Wallace, is the driven governor gear plastic? Phenolic? Or iron/steel?

I can see it as working. Cannot see but have increased wear, narrower crank tooth within driven tooth though from the smaller surface area contact.

S.U.

Governer gear is plastic probably nylon.

Most of these roller kits I see come with a new plastic gear.

Maybe that’s a retrofit for older engines.

Just a little shout out and thank you to Mr. Kim Liu at the WSEPO Store in China who is reviewing this thread and the images I posted in an attempt to Help me find the correct parts.

Aliexpress only lets you see one small photo.

This thread has many better images I hope help.

I am cautiously optimistic this crank will work with little to perhaps no machining…

Mr. Liu says we have a very interesting website and asked if he could join and post here.

I said I think that would be very nice and he should apply for membership.

I never payed much attention to Aliexpress.

This must be Mr. Liu’s web page?

https://wsepo.aliexpress.com/store/2997036

This must be the ~ 200cc HF clone engine section:

https://wsepo.aliexpress.com/store/group/168F-GX200-2KW-3KW/2997036_511740460/1.html?spm=2114.12010612.8148361.2.8f353773urdduq&origin=n&SortType=bestmatch_sort&g=y

Charging coil looks interesting:

Looks like gaskets and the smallest parts are the only option because of shipping. For example an inverter generator is ~ $260 for shipping.

Solar-Fuel, onward !

You need to have the correct flywheel to use a charging coil.

It has to have magnets inside, often you find they come with ring gears too.

Snowblowers are a good source for a lot of these parts.

Parts are in play now coming from across the seas and continents near and far…

First parts came in today.

The new crank.

AS you can see this is a short taper crank 5/1 and its about 1 inch at its thickest.

This is ye old crank.

Taper unknown and I think it might be as high as a 10/1.

one inch diameter and it drops to about .890 at between 7/8 and 1 inch, its hard to measure.

Next stop the machine shop in about a week when my next time off starts.

Quite nervous about this I just took some quick and dirty measurements to see if there really is enough steel there to make this work.

I am cautiously optimistic.

Also the cost with shipping tax, brokering and gouging this crank cost 100 USD to buy.

I could not source one anyplace other than China direct.

So current build cost is now at about 150 US Dollar

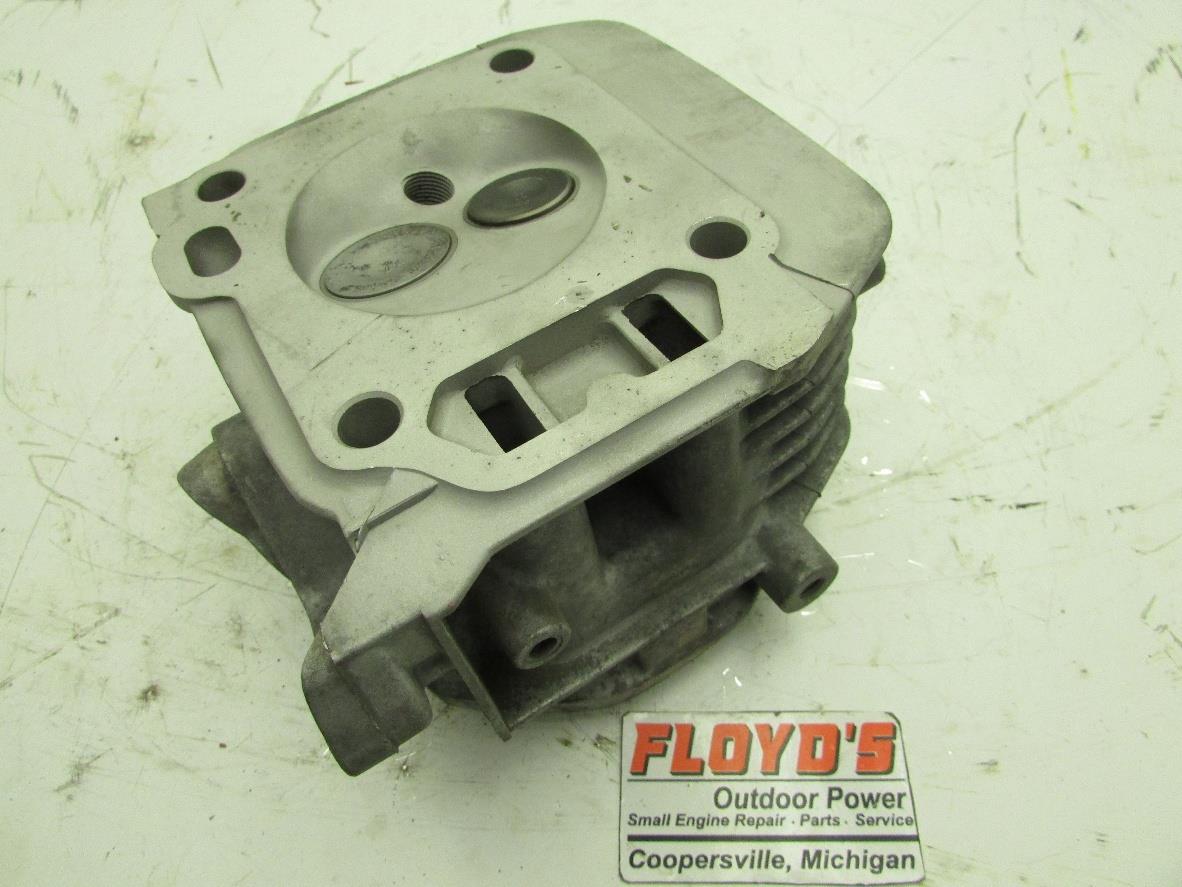

Waiting for a day I can head over to this local aluminum wheel repair shop and take this head in for a conversation.

The fellow seems to know a lot about welding and is willing to weld up another head for me.

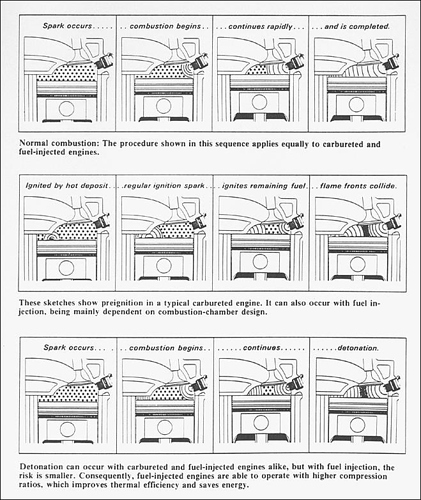

Next photo shows the really cavernous chamber on the GX240.

I don’t claim to understand the Honda engineers motives, they probably were trying to make a clean burning head and decided low low compression combined with the right amount of timing and steady RPM could deliver some clean exhaust numbers.

But I am not too keen on this.

I want a closed chamber on this with a tight quench for better economy and easier tuning.

Morning another day of the same old same old.

I know what I want to do and its just a matter of finding the right guy and make the time to build the head.

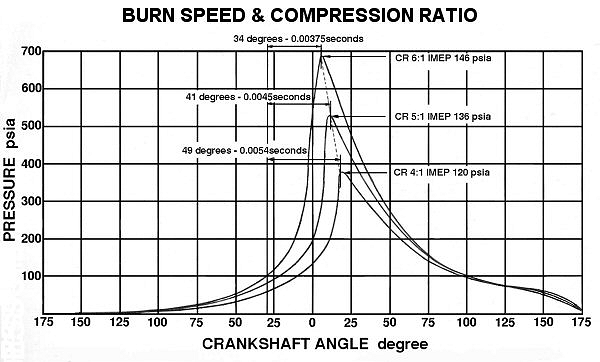

Here is a very long and interesting list of discussions and snip its all on the subject of quench and swirl.

Both of these can be very important to understand when building a producer gas engine because these engines can also use the turbulence to increase burn rate and mixing.

I am just going to add stuff I think is worth looking at for conversational purposes too.

The first of my parts are now at the machine shop.

The machinist wants to see the Kohler crank in the block too for further measurements.

So more to drop off.

I crossed the street to the Wheel welding shop to see about getting 5 or 6 beads laid across the head.

The welder is ill and not there but an old man I have not seen since the 80s walks over and asked why I had a head in my hands.

I knew very well he knew what was up to because as a teen I used to buy parts off him ( I guess he is in his mid 80s now, the owner of this welding shop and once the owner of a large honda motorcycle and snowmobile dealership )

So we talked flat track bikes, snowmachines and bath tub racing for nearly an hour.

He did not offer me a deal, never did 30 ago when I raced as well.

I did not explain this was a gas engine ( wood gas ).

I don’t think he would have gotten it…

But talking shop about race engines did put a little sparkle in his eye

I don’t think he remembered me though HA HA

I have a question on where to find some info on conversions. I’m getting ready to buy a genset that looks like a duplicate of the one you’re working on. The Kohler engine is set up to run on natural gas and I’d like to get to know what’s involved converting it to wood gas. Are there any threads here on the subject? So far I haven’t had any luck finding anything. Thanks.

Can you post picture of the unit?

The K181 engine that came with the generator when I started was a little derated for natural gas.

It was about 8 hp and that not much to ask to spin a 3000 watt generator.

The conversion is simple you just need to make a producer gas carb and mixer.

Ignition timing is pretty easy to advance on the K series engines because the points are easily accessible under the carb.

You probably will not be able to get the full 3000 watts on wood from this engine.

But you will get more from it than you might if you started with something that had a smaller less powerful engine in the same electrical power rating.

K 181 manual as you will see leafing through this engine is about 1/3 larger than a contemporary GX200 you might find on a set from Harbour freight or a Champion dealer.

SO COLD!

I need to warm up the shop and pull the crank out of the kohler .

Machinist wants the crank and block for measurements but I can not get enough heat on with my 1500 watt electric.

I have gasoline blow torch running in there heating up my drum heater with the electric to provide more BTUs but its -9c

It will take hours to heat that up enough to feel my hands.

First sign you getting old you do not like to work in the cold.

Shop is well insulated I am fighting the fact its probably colder in there than it is outside HA HA.