Hi Tom, the WK Gasifier that Wayne design has a good turn down ratio, meaning you can idle the engine down, and the gasifier will NOT cool down quickly which keeps it from producing tar in the gas flow. It still has its limits. In the Imbert Gasifier design it is important to keep it in the optimum running temperature for it’s design, which would be the load of the engine for the genset. If you are holding a 3/4 to full load for the gasifier design you are okay on the genset. But if you go to a low load condition continually the temperature will drop and possible tar can be produced, not good for the engine of the genset. So to anwser your question, yes you can just use a bigger hopper, if you can keep it at the optimum load range on the gasifier. That would mean keeping a continue 3/4 to full power load on the genset.

So using two gasifiers you could have a wider load range for generating power. With Kristijan idea you could have two smaller gasifiers. Use one or smaller power demands and use both for larger power demands.

This could also be used with a vehicle.

Jeff is talking about a flex fuel wood or charcoal gasifier. Kristijan is testing his new gasifier to see if it can run on a fuel mix of wood and charcoal. This is all great stuff in the world of gasification for today and future use.

Bob

Thank you Bob. What you say makes sense, if you have one of those new stiles generators, inverter generators (?), where the rpm s vary with the load applied. The old style have to keep the rpm’s at a rather high level. Yes, the pull on the gasifier varies with the load, but I don’t think the variation is as much as to require a large turn down. I’m a vehicle guy and don’t know much about generators. TomC

Update:

No word back from the machine shop.

I told them I was in no rush, never rush something unless its important and you need it right now.

Sometimes this will save you money too.

I will drop in on Friday I guess and see whats up.

Might email them.

Further update:

Got an email from the machine shop.

They are puttering around with it off and on when they have free time.

This is fine…

No pressure…

But I have this sickly feeling the whole enterprise now is stuck in the expensive care unit.

This shop is full of CNC equip and I get chest pains just thinking about the cost of the machinery in there.

But in for a penny in for a pound, this may be the most expensive generator rehab I ever did when the dust clears.

I could have done without this but I bought a scrap engine for 20 bucks off a guy tonight.

NUTS I buy scrap now, the guy even told me he was about to toss it out.

But I came along and bought it for 20 bucks…

Its an LCT 291 cc engine and its from the same family as the Honda GX240 its just pumped up a little beyond the 240-270 family bore size ( in so far as i can tell )

The head is a bit different but will fit and the rest of the bits are a bit different but fit too.

The real interesting bit is the 60w 12 volt lighting package, and the crank case cover might be useful too it has a nice dip stick on it.

I like dipsticks easier to read than looking down in holes…

The exhaust is very different and might be of use.

The car has new linkages and bits that might have some sort of possibilities too it.

I didn’t need any of this, but oddball stuff sometimes comes in handy when you least expect it.

Here’s one just like it only it worth more than 20 bucks because it has no holes in it where parts came out HA HA.

I do the same thing ! ![]()

As the saying goes one man’s scrap is another man’s treasure.

It is crap I pulled the engine down and must confess to a bit of disappointment in some of the different parts.

This engine is a Liffan not LCT as I thought.

Might as well post some pictures I guess.

Will do that later.

Still no word from the machine shop.

Siezing an engine is a lot like falling to your death.

Its not the actual act that does the most harm.

Its the sudden stop.

Too one side I placed ye old 73mm Honda GX240 piston and rod and to the left you can see the 80mm Liffan piston and what remains of its rod.

Mechanism of failure seems to be starved of oil.

The rod broke at cap and the crank came around and smashed it into the top of the block TOO BAD…

This engine could have been rebuilt and I might have ever tried to put a new rod into it and just washing the aluminum off the crank pin and polishing it up.

But as you can see from the violent stop this was not going to be the fate of this 291 Liffan.

Other surprising features it has no counter balance shaft.

I imagine it was a little prone to vibration without it…

I have almost nothing new to report.

This is taking me much longer to do than I am used to and I apologizes to all those that have been hanging on this waiting to see the welded head modifications.

I just can’t proceed without the crank and that’s still not finished

But I have some new developments.

The Liffan 291 crank does match the Honda and that means the flywheel is compatible.

Why this is useful to know is because I intend to swap out the Honda parts for the Liffan and including the 5 amp Liffan lighting package in my build.

You can never go wrong with some extra power and now I have 12 volts at 5 amps to provide supplemental power.

Tin work a spare head flywheel ignition cam…

All this is stuff i can use.

I will look at the cam real hard and see it its got a different grind that might be useful too.

I can use this to charge a battery in addition to the output of the generator

Next week, Monday maybe I will drop into the machine shop with some coffee and doughnuts and see how things are going.

From March third I had an inclination that something was up.

The crank is done, machine shop called Friday.

It was expensive…

The wife is not impressed with me on account of the budget blow out.

So the high compression head is now off the table and from here on in I am just going to do the bare essentials to get this set operational.

Another day another thread and I will look at building a proper producer gas engine.

This will simply be a gasoline fuel unit

Physically and mentally exhausted today.

But here is the prize a Honda style crank modified to fit a Kohler generator.

Its going to set me back another 50 bucks for engine internal parts and gaskets.

So I decided to get back at that head…

Today I stripped the clone head and put it in the rod oven for a few hours at 475 f.

This was the burn out the oil in the casting and prepare it for welding.

Going to get this project back on the rails here shortly

I can never let things be, its a flaw…

On the clone valves are a ridge from the manufacturing process and this bothered me because I can feel it under my thumb.

It will cause flow irregularities and this will cause pumping losses and power loss increased fuel consumption…

Not much but its there and it pisses me off.

So I took the valve to the other side of the grinder and removed this ridge and because of haste OI nicked the face of the valve

Bugger!!!

But I have one off these.

Keep your eyes open for one of these fellows.

By no means is this a perfect tool but for a light clean up of a valve they are worth having.

Join the club!! I know the feeling. I’m not a good craftsman and everytime I see something I don’t like I go back and try to correct in and screw it up BIG time. TomC.

Your only as good as the material you start with.

So if you start with nothing ( of any particular value ) and end up with something your ahead even if you screw up and ( don’t quite achieve the master plan )!

The head is now at the welding shop.

The guy is an old hot rodder from back when.

We talked a little shop and then his father a man in his 80s joined in too.

So I am waiting for a phone call Monday or Tuesday to pick up the head with the combustion chamber filled with weld.

I just hope this guy is as good at welding as I am hoping.

Another update.

head is still at the welding shop they are busy as hell these days with all the bent and damaged rims for this springs pot hole season.

The roller kit from Everest parts in Florida is play too.

Should arrive sometime in the next week or so

This fellow is selling copper thin head gaskets.

I might try one of these.

The seller offers to make thinner ones on his website.

https://www.ebay.ie/itm/NEW-Honda-GX240-8-HP-CYLINDER-HEAD-GASKET-COPPER-8HP-ENGINE-/163321096621

Why the weld and copper gaskets?

I am trying to make the most of this for a very tight fit.

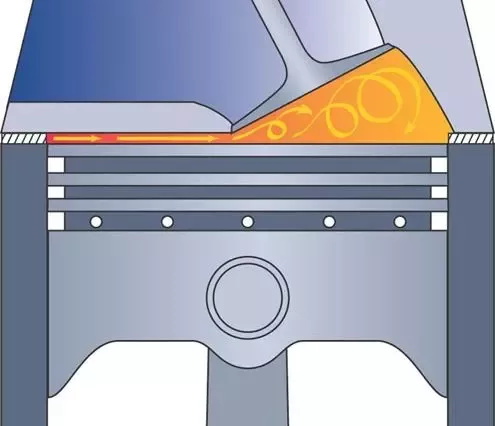

If I can get to .030 clearance between the welded chamber and the top of the piston then at speed the escaping gasses from this quench area will promote excellent mixing for improved power and economy.

There’s also something called swirl.

This has to do with the shape of parts and it was a common cast in design adaptation you would see on many engines in the 1980s.

You sacrificed flow to improve mixing for reduced emissions and gained a little bit of turbulence.

At this time in engine development the quench had gone out of favour because it caused emissions to increase

So here are some images of the quench and swirl and hopefully soon

I can get the head home and start working on that

Here is another interesting photo of the GM 2.5 litre iron duke head.

Thats sort of what my head will look like

And an image that shows this quench effect.

I hope to get an improvement in power and economy of 10% with these changes.

And the applications to wood gas are also there

Some progress.

The roller kit is now here.

Head should be welded up tomorrow and I can start on that too.

I was going to post some pictures of the engine assembled today.

But closer inspection of the new piston left me disappointed.

Its been roughed up in shipping and I have no patients for this kind of thing.

I just won’t use it.

So shopping for more parts.

The Saga continues…

I noticed Creighton Mine on your shirt. Is it near where you live? You would think that when you buy something and have it shipped it would come not all scrached, cracked or bang up when buying it new.

Bob

I used to work at that mine.

The actual town ( a company owned town ) is gone.

The mine still produces nickel copper gold silver cobalt and a host of other platinum group metals.

At one time a hick up in the schedule at Creighton would make the pages of the NY times or wall street journal…

I sent an email to the seller.

This was a cheap part very cheap so I am not broken up about it.

I know a guy in Asia that is a Honda dealer and I might send him an email asking for the latest offerings from Honda and buy OEM stuff.

Only we pay top dollar for Honda parts, over there they are cheap…