Jesse,

Do you realise you’re one of the youngest gasifier operators in the world, ever?

I wish every child could get the quality of education you, your sister and brothers are getting. It doesn’t matter what is taught. It’s what you learn that counts.

Hear, Hear, to what Jan-Ola Olsson has said. And I might add it’s all the good things that will help others that really matters.

Bob

Hi jessy cool vidio of learning and keeping mike lerosa gasifier on display and restored condition, as said mike would be happy for your learning gasifier experiance, Though as said be carefull when lighting as wayne said not too be faceing the burn tube too close could be stored gas, and severe burn ones face from a flass of excess stored wood gas. Remember too allways expect a posible flass and stay off too the side,with fans running a little ahead of time should pull any stored fuel away from the burn tube far enough too prevent a posible burned face or flying char in ones eye is posible. The old saying goes if there is a way for an accident too happen it will.CHEERS.

Thanks for all the information. I am looking for an engine to run on the gasifier. Jesse

Jesse,

I am so impressed with your wood gas knowledge and ambitions. Also, I am amazed that you have made this much progress so quickly. I was expecting months to get this far along.

I looked up Kristijan Leitinger’s introductory post to the DOW forum, because I remembered that he started in wood gas at a young age (he’s still young, for that matter). Kristijan indicated in that post that he started when he was 13-years-old. I remember the “One in a Million” thread in which it was concluded that there was less than one in a million who are interested in wood gas. Those starting at your age are more like “One on a Continent.”

I am 65. I have a 99 year-old friend who laments the fact that so few today have the ambition to get their hands dirty and make something or even fix anything. Back in his day, if a person wanted something they had to make it or work for it. Things are just not the same today. My machinist friend, who has helped me some with the Toyota project says there are three kinds of people: Those who make it happen, those who watch it happen, and those who wonder what happened. Jesse, I can tell that you are going to be one of those who make it happen. God bless you.

Hello I have been working on cleaning out the hay filter. thanks Jesse

I am sure the gasifier will perform better with some fresh hay in the hay filter. I know mine light up and the air flow seems to be better.

Bob

Do not worry or fuss about the flare from this LeRosa rig.

Mike never did.

He insisted that he let the engine proof his made gas.

Ha! I learned this from Mike LaRosa, too. He would not flare unless someone absolutely insisted.

Some of the best “pure” color four-stage filtered woodgas (intended for G-T-L) gave poor engine loaded down power for me.

And sometimes straight-out unfiltered woodgas that would not flare at all, but would start and run a loaded down engine with good power.

Not that I am recommending engine running straight-out woodgas.

Too likely to have a still-too-cool-of-hearth tars gas. Too easy to have sweep-through ash.

Regards

Steve unruh

Side note: Mike had stated some years back about having had a bumper sticker about “No blood oil”, so I bought him that bumper sticker that is on your gasifier.

Does anybody know were to find information about an inbert gasifier.

Jesse

JesseN., actual Imbert was a man who had original patents on a system beginning in the 1920’s, up through the 1950’s? He was able to get investors and set up commercial making manufacturing concerns in different places throughout the world.

His systems were for light weight mobile applications. Had formed walled hearth core flows shaping. Means always direct contact of the hot glowing char, the different stages of gas flows, and released hot ash direct contacting against those cast metals walls. And later some WWII German system with ceramic cast walls.

These are small active volume internal area units. Rely MUCH on high flow velocity internally to function well.

The later; BETTER, Nordic ash-slope systems were much more durable, easier to manufacture, and maintain in actual service.

Still velocity-as-king, dependent biased systems. The design math’s for both are similar and here in the Library section.

The WK is a large hearth core active area volume system. No nearly so much a flow velocity dependent. Uses a longer TIME-in-residence bias. Said to be FEMA derived. Hmmm. Actually very related to the older town stationary gas-plant gas makers.

Has it’s own design maths. Published in Chris/Waynes book. Discussed much by builders here on the DOW WK-builders premium side.

Then . . . . there is the Dobson systems. HUGE internal volume, with all-active, super HIGH throughout Temperatures, with low velocity and l-o-n-g, l-o-n-g, gas-in-residence Times hearths. This type is larger, heavier, and has not proven amiable for mobile use.

For the internal system bias’s of LONG Time-in-residence, with huge active internal volume the Community Power Systems and IISc/Mukunda systems are very related. Without the Dobson super high Temperatures.

These last three along with the old big gas-plant systems will post up fuel-weight to gas-out volume conversions efficiencies that the smaller, lighter made systems cannot match.

Good example that an absolute single-stage efficiency is not the goal!

It’s what the system can and will do for you! Converting your own, owned resources into measurable productive working for you and yours.

Of course there are other systems types.

But I only concern about those able to use site grown woody materials as fuels inputs. With the least, minimal processing of those woody fuels.

The all-fuels-stocks must-be ground-up. Some needed pelleting or artificial made-up chunk/pucks “fuel”. These systems are not in my opinion DIY doable. Or desirable.

Too many special-needs fuel making steps. Requiring too much machinery. Driving into Too high of make-it-work capital investments.

Regards

Steve unruh

Hi Jesse, if you just look to the right of your title of your thread… you will see thr word Home, Store, and then Library. Click on Library then scroll down you will find “The Imbert gasifier”.

Lots of information on other gasifiers like the Dobson Gasifier and others. Have fun reading up in this DOW Library. It is the best Library of Gasification compiled in one spot.

Bob

Jesse,

In everyday talk we tend to call all of them Imberts - any gasifier with the restriction midways, inbetween nozzles and grate. The inverted V-heart is pretty much what Kristijan and I have been using, but for some reason we called them Imberts.

There’s a lot to read about different style gasifiers already in the library section, right here on DOW.

Edit: Ops, Bob beat me to it

Hi Billy,

I tried sending info, lost it. Take 2. I have a detailed imbert built “to the specs” on this site.

There were a couple of minor dimension changes made, which I note. I have a vid on Youtube

of a small roto tiller tilling on woodgas.

Go to the Small Engines category and scroll down to, “My first small engine run”

Click on it and a Table of content page will show. Click on first item and scroll through

by the page or click any item to view that item. It’s long and detailed with “How I did it”

solutions and some vids. You might find it helpful. Feel free to ask about the build if

it’s not clear. Pepe

PS You are the coolest kid I know. It’s great to see your interest in and knowledge of gasification.

Mike was a great guy and its nice (beautiful actually) to see you keep him alive so to speak.

God bless you, young man, I know your dad is really proud of you. We all are!

Pepe

Here’s my site to save you the search;

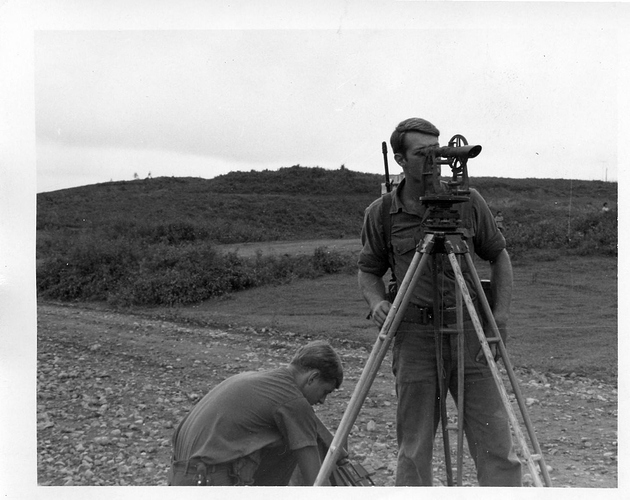

Another connection I had with Mike was that I was also a surveyor. Here I am with our tape man

Jim Jensen on route 1 heading west towards Cam Lo vil. Jim probably saved some lives when he discovered

a booby trap near a rail bed road we were later surveying near Quang Tri.

Right Al, these are tested and proven dimensions. Start here, experiment later!

I followed these and am satisfied totally with the results.

Thanks for all your help to Jesse guys, I appreciate it. Turns out, Jesse’s great grandpa, Elvis, gave him a propane generator system to try on this thing. i need to look into it a little to see what it actually is, but in the mean time. Does anyone know if there is info posted here about converting propane powered engines to run on wood? I found a post from 2012 abou the subject, but there were no answers to the questions at that time…???

Hi again, Billy and Jesse,

Let me explain where to start on Table 5-2, Imbert nozzle and hearth diameters. Start with the

“Range of gas output max Nm3/h” column. The numbers in that column are the horsepower

number of the engine you are using. Choose the number that includes your HP. You can see

there’s some room here for different HP engines using the same specs. Don’t let it throw you.

Use the dimensions line on that HP number to size your gasifier components. It works, you’ve seen

mine run! Refer back to my site to see my build to these numbers. Sorry, no info on propane.

Good luck, Pepe

Hi, again, again,

I just went through my site and found a schematic profile of my finished imbert with the

real spec sizes compared with the “what I had materials” sizes. They were close so I

took a chance and it worked well, as the vids I made show. I was totally surprised. I

expected some penalty in performance.

The schematic is number 61 on my site, Dec 9, 2012.

Billy,

I’m going to opt that the gen will run on a different gas (woodgas).

You may have to fool with the fuel air mixture due to different gases

having different energy content. I’m not sure you’ll have to fiddle with

the timing too much or at all. Try it without touching the timing or mixture just

to see if you can get it to fire. You could experiment with a small cylinder

of propane from a soldering rig. Point the nozzle at the carb opening and crank

it over and see if you can get it to fire at all. If it does, woodgas will run it with

the proper fuel air mixture IMHO.

I have successfully run my 5 hp rototiller on woodgas(full open) with only a minor

air adjustment needed.

Pepe

A friend of ours had a Chevy Aveo the the engine needed replacing he didn’t want to pay to replace it so we bought it. It has a 4 cylinder engine in it the right size for a LaRosa gasifier. Right now I am planing to put the small LaRrosa on the Aveo. Maybe have it finished for Argos.

Jesse