Thank you JO, that is a beginning!

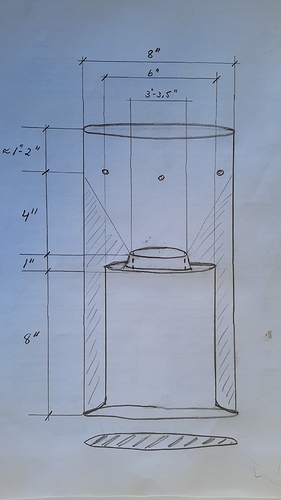

Getting the outer cylinder(s) on the same drawing would make it more complete.

All functions are more or less interwoven; how they interact depends on chosen proportions, selected flow areas, etc.

What is now clearly seen, is the very short nozzles; they will keep the succing returngas flow streaking on the cylinder plate and making it glowing hot around the nozzles, this is going to the WK system needing very heavy cooling by fins on the outside!

If you want to avoid this, make the nozzles 1,5 – 2" long to avoid the return succing streams burning the cylinder plate.

This has of course consequences on the process cone’s diameter. All the cone proportions will change.

If you want to go on with the same hearth cylinder, the cone volume gets smaller, the gasproduction will be lower, you will need smaler fuel bits…

This all tells that a gasgenerator has to be constructed from the internal process volume outwards — not starting with the metal holding it!

As others have stated, the construction starts with a GOAL, the measuring follows that goal with established rules…

Otherwise it will be more or less “build and burn” or “build and smoke”.

The rules are to keep the construction within those extreams.

…

To continue on the so far effort, weld 3/4" SS nuts on the

outside of the hearth cylinder.

Screw (whole length outside threaded) nipples (soft iron) in them.

On the inner ends of the nipples, weld nozzle tips (smooth bored SS nuts).

Then make decreasing diameter upside-down L- profile rings to trim the restriction.

Make the reduction tube’s lower end hoistable, or then make the restriction rings pilable to decrease the process cone height…

Otherwise, restart it all…

The reduction tube seems to be unnecessary high; it may clogg…

If you study “GENGAS”, you will find the ratio between gas production per second and active cone volume in liters; for busses and big trucks.

From 11% down to 4% for lawn movers, etc…

Fuel bit size goes accordingly!

Max