I found this air control actuator out the door much cheaper $ 27.50 than a cable like a boat steering cable, I needed about 10 foot cable to get up by my shifter with the lever. This is much easyer on my truck because i moved the air control i bit farther back than the book version. ANY way this 42 pound 188,n is much lighter than a big cable and much lighter than the 200 pound actuator , i show the 200 pound one and the 42 pound unit. LESS THAN 1/4 the weight.

THE small one seems / feels strong enough for air control ball vauve. THEY BOTH have a gear box that gives it its power. HERE the switch-6 wires-two in center are hot and ground/ the two on the ends are forward and reverse- the jumper wires go to criss cross to the other two end prongs.

THE small one seems / feels strong enough for air control ball vauve. THEY BOTH have a gear box that gives it its power. HERE the switch-6 wires-two in center are hot and ground/ the two on the ends are forward and reverse- the jumper wires go to criss cross to the other two end prongs.

SWITCHES are made like power window car switches,as it pops back to off position in center after letting off the switch.

SWITCHES are made like power window car switches,as it pops back to off position in center after letting off the switch.

Does it open or close all the way only, or can you just nudge it a little for fine adjustments?

They go 2" forward then 2" backwards and stops automatic when at end of the the stroke/ or you could stop any time you let off the switch- might need a light to let know its full open or closed.

I think the smallest one is better choice, it is much lighter,since weight adds up so fast with all that is built into our wood gas vehicles- the smaller one in 2 inch shorter and about 10 th of the weight.but still seems strong enough,with its 40 pound push or pull rating- i pushed on it hard and it keep moving.IF i had one of them toilet slider valve, i would use the 200 pound push/pull, bigger unit.About 6 bucks more for the much more heavy duty unit. There dont seem to be any other sizes in between 200 and the little 188 N /42 pound unit, so far anyway-around 25 bucks range.

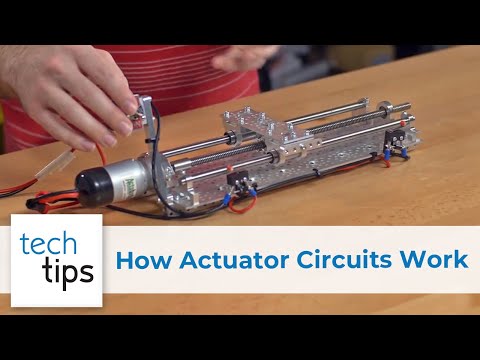

If you want to cut weight, make it fit better, etc, actuators are just dc motors that turn a threaded rod, and the “nut” moves. Then they change the gearing for motor speed or power. The end stop are just contact switches with diodes so you can reverse the polarity. If you need completely accurate replicable control, between open/close then you probably want the stepper motor or a dc motor with a position sensor like inkjet printers use.

But here is a pretty nice explanation of the different styles.

This is a great explanation of a limit switch circuit.

There are all sorts of videos on diy actuators, from everything from windshield wiper motors to the tiny cheap plastic gearbox motors used in cheap robot toy cars.

The 100 dollar ball valve closer (not the actual valve) on my parents furnace was a small dc motor that was geared down, and probably the same size as the dollar toy motor.

THANKS for posting- i hope i dont have the opticle hall effect cut off sensor. the other two type cut off designs i might be able to repair if stopped working, hopefully they keep on working, though now i must pull the back cover to see what style / type cut off switch is used. VERY informitive knowlege.

They aren’t cut off sensors. They are position sensors. Chances are with a position sensor there are also a cut-off sensors for calibration.

They are used for position accuracy, so 31.3 turns might be half open.

the hall effect style work almost exactly the same as the optical ones with the hole in the disk, except the magnetic ones use little magnetic bits on a plastic wheel similar to an audio tape. And the positions can be much closer together for much higher accuracy. Both styles use a microcontroller to keep track of the position, and take input.

I assume, you can ‘rewire’ around it because they most likely have end stops to calibrate. The accuracy is like 1/1000ths of an inch which I suspect is a much tigher tolerance, then you need for your application.

I dont like the circuit board defrost timers in the newer refrigerators either- on the old school defrost timers, they were much easier to test that the clock motor was turning/ because when the defrost timer clock motor stops, it will either be stuck in defrost mode or not make a full 24 hour cycle to put the frig in defrost- hence why the freezer fills with frost and stops working. THE old defrost timers you can just turn a shaft screw to turn the defrost of and the frig comes back on.OR you could rotate the clock motor shaft untill the points pop down and then you can tell if the defrost coil is working,if the freezer is cold enough, or bypass the freezer temp sensor and the defrost coil can be tested that a way. ON the newer frigerator units, you would have to unplug the defrost timer and power up the frigerator motor and or defrost coil with jumper wires,to find the defect part.

That is why I wanted you to see how easy the basic circuit was. The rest of it is just a nut on a screw, and a motor with a gearbox.

The circuit board style is for like 1/1000th accuracy for like a lathe lead screw, which I don’t believe you need that much accuracy for this application.

The old appliance clocks used the AC frequency as the timer for the clock which is pretty clever. Although ac frequency can and does vary slightly… ![]()

I think in the “old days” (which now include part of my life ![]() ), the folks running the generators could compare a clock running on the generator to a standard clock, and speed up or slow down to literally make up time. Maybe @Bobmac could speak with more authority on this.

), the folks running the generators could compare a clock running on the generator to a standard clock, and speed up or slow down to literally make up time. Maybe @Bobmac could speak with more authority on this.

Now that you mention it, it was used quite a bit with PTO generators on dairy farms. It is a quick check, and you just have to be close. Nowadays, you could just get a cheap handheld digital oscilloscope to use.

THE old clock motors, were just little electric motors geared about 12 or more hours untill it makes a full circle and then a points would spring down and touch the power to turn on the defrost coil while at the same time shuts the ac pump off/ as the little gear motor or clock motor turns/ in 10 or 15 minuts or so the the point pops back to the ac pump power/and turns off defrost coil the same time- some time the clock or gear motor stops/ and sometimes the defrost coil burns out/ then you get a freezer full of snow like ice/ and no air will travel into the frigerator section/since all the fans and air channels are pluged with ice snow. ALL GOOD KNOWLEGE IF YOUR FRIG GETS FULL OF ICE IN ICE BOX SIDE.