There has been some discussion on making tar lately. So instead of filling someone threat topic up on this I created a place to discuss it here.

What makes this Tary nasty sticky black gooey stuff that will mess your engine up fast?

Biomaterials, most common for gasifers is wood, bark, bamboo, ect.

So what ideas and proven ways are there to prevent tars from leaving the gasifer?

Open for discussion.

Bob

I personally think that anyone can make tar in any well built gasifer if operator does not follow the correct steps in running a gasifer and there are many.

Lets start with loading the gasifer up after cleaning it completely out of wood charcoal and ash.

I have learned from the DOW site members, that you need to refill your gasifer first with some ash around the drop in restiction plate. This will help fill in any small leaks so all the gases/air goes through the restiction opening, this is very important that all the gases go through this opening.

Next fill the gasifer firetube up with charcoal, but not real fine stuff. Popcorn size and a little larger up pass the nozzles and to the low hopper. If you have brands pieces of wood put them on top of the charcoal.

If you just fill it with wood it will take a long time to burn it all down and you will make tar doing this for sure.

Keeping everything moving down smoothly with out bridging is another important thing.

If you do not have a charcoal reserve below the restiction opening and you have a bridging problem you might burn up the charcoal in the firetube area. When the bridging in the hopper break loose raw wood can fall down into the firetube that as not been pyrolysis enough causing tar to go through the gasifer while the wood is cooking down.

My gasifer has a large charcoal reserve all the way to the grate and through the grate.

A while back when I first started to drive my truck on wood I pull into my drive way everything was running great. My hopper temperature was climbing up and I didn’t think it should be out of wood yet. When I open my hopper and the smoke cleared I saw for my first time ever what wood bridging looked like before it would cave in.

I was well passed my nozzles with charcoal when I poked the bridging down. The bridging had a dome area under it and raw wood fell in pass my nozzles. I now had a burning barrel effect going on, flames rising up out of the hopper. I used my poking rod to close my hopper lid fast. My engine was already shut down, so I let it just cook down.

When I open the hopper up minutes later dark, black smoke came out, Now that was tar smoke for sure.

I am sure if I was driving down the road and this would of happen I would have been okay because of the large charcoal reserve would have caught most of the tars and burned them up into the good gases.

I am sure my hot fire lobe was at the restriction opening or pass it. The charcoal below my nozzles was may be 5". I had good power going all the way to my house and into the drive way to park, and it was idling good. The temperature at the grate was normal only the hopper temperature was climbing up. I think it was a great observation to witness. It has never happened like that ever again.

Has anyone witness this happing in there hopper?

Bob

Just a free thought since I am new

I’m sure water content affects all tar production, but I would think softwoods such as pine and Doug fir would make more tar if ran to cold in the fire tube, since they tend to have pitch pockets in the wood quite often around damage like wind or snow breaks. I would assume to run these woods the temp must be kept up. To my understanding hardwoods would require less temperature to break down there natural tars since they are so sense and seem to have less pitch or sap just a thought

Yes Marcus, different woods do produce different amounts of tar. Like you said you need high heat to change the tars into good gases. One of our members Al Flick @trikebuilder57 design his hopper lid to collect the tars and then reintroduce the tars back into the center of the hopper wood to be burned up. If you can burn up all the tars you make in a gasifer using high heat, you will convert it to good gases to be burned in the engine. The problem is can your metals handle the high heat to do it.

I am not sure what kind of wood he is burning in his gasifer truck.

Water can be converted to Hydrogen but there is way to much water vapor to heat ratio to convert it all. So the water vapor does go through the gasifer charcoal bed and out of the gasifer the trick is to not carry any tars with it. It is a real balancing act to make a gasifer work properly and the operator has a lot to do with it. Some gasifers are easier to operate.

Bob

I think that my problems with tar often arise because it is clogged somewhere, I am too bad at cleaning, and at knowing where to clean, before it gets too bad draft through the gasifier.

From a beginner.

Don’t run low of charcoal .!!

It is like peeing on an electric fence . You will remember it and will not do it again

Ha, ha yes Wayne, precisely. I have heard of boys doing that. I have been zapped by the old electric fencing but not that way. Ouch!

The CHARCOAL reserves is so important from the nozzles down to the bottom of the gasifer.

Wayne, I noticed on your last build the Wilbur Smith gasifer that the grate you built looks larger in diameter than some of your other builds.

Was this so you could hold more charcoal out to the diameter edge of the grate, and have less slippage of charcoal?

Bob

Look at this:

http://forum.driveonwood.com/uploads/default/original/3X/7/8/78a2bb67ae0b36407a78d04ead85f7262494fb4d.jpeg

a picture link of the shown upper system of Joni’s last running well GJ 9.0 system.

Black gooey asphalt-like tars coated.

This IS NORMAL upper woodgasfier system condition.

Now a picture of his sectioned downstream cooler tubes:

http://forum.driveonwood.com/uploads/default/original/3X/8/c/8cc362cfc5303724f8d8976a210cdd9c442df981.jpeg

Just a light soot build up. NO TARS! The intended upper system made tars were HOT Charbed converted.

I am just not good enough PC to put up his engines teardown pictures off of his video. NO TARS, or soots.

Why? Good basic design. And especially OPERATED Well.

S.U.

Yes Mr. Bob

The grate is a little larger than previous grates but seem to operate about the same .

Yes Steve, I agree on the 9.0 system Joni built. Have you notice the shape down in the firetube betweem the nozzles or tuyeres? It has filled in and made it’s own unique shape, straight lines in the firetube very interesting protection around the the whole inside of the firetube with ash/charcoal/baked hard tars. The up part of the hopper or bunker is sticky looking but the lower part is also baked on and hard. It doesn’t look like it was ever strapped out. He just let it form it’s own hard shape by the using of the gasifer’s velocity and heat.

Yes the cooling pipes have very little build up in them.

Joni filter has done and amazing job keeping soot out of the engine.

Again, all I can say is, Good Job Joni on your design and your operating abilities in gasification.

Bob

Hey BobMac,

I used Joni’s picture set as the most recent and available.

You know; WayneK knows; and all actual hard running wood gasifier guys know that the upper hopper system is a gooey, tarry mess.

THIS IS NORMAL. At this stage in a wood gasifier you are supposed to be making wood tars. Starts the phase of separating out the actual wood char.

Then in this upper system, and mid-system above the air nozzles is where you remove the woods water vapor. And especially in the case of the WK systems refine out the light volatile tars fractions from the heavy, heavy tars.

Tars through to the engine will always be an Operator problem!!

A good operator will refuse to send them thru.

Poke. Shake. Dumped out, and fully grate-up reload. Blower, suck&blow until systems beds and HEATS are established . . . until full tars conversion is taking place.

IF the input wood fuel is so poor . . . . IF the system design so poor that tars conversion cannot be done . . . then STILL an Operator problem to not have shut it down; and have sent those unconverted tars to the engine.

S.U.

Yes Steve, I agree in all the stages the gasifer works through. A well design gasifer systems is a important key along with a operator that knows his system and how it runs. And knows what to feed it.

Like I have said and everyone that knows, any good designed gasifer can and will make tar in the hopper. Keeping the tars from leaving the gasifer is the operators responsibility on how he is operating the gasifer properly.

Bob

And how do you become this good operator?

You are becoming this JanA.

You diagnosis of your cyclone failing. First awareness that it had happened. Then wiliness to cut it apart to see why. Then acceptance that it was your use of it forcing bad-wet-dirty gasses through it.

Your realization now that you will probably have to detail clean out your whole rest of your system.

And you’ve never blamed your wood. Your vehicle. Or other causes.

Much respect for your perseverance Jan.

Best Regards

Steve unruh

Hi Jan, what Steve has said. You are already well on your way of being one. You are doing it by being a doer builder, operator and maintaining. The more you operate your gasifer the better you are getting it down. I can see it, and I am sure others can see it too. Good job on all your accomplishments.

Bob

Thanks for the kind words, but it feels like I have LONG left.

See my link.

Jan, Just a thought. In reading pld postings, I saw something about ‘‘soot’’ build-up. If you are seeing black build-up in the manifold it is probably ‘‘soot’’. Mr. Wayne has talked about his manifold getting built up with ‘‘soot’’ to the point it finally catches fire and burns out. That is why everyone says don’t gasify a vehicle with a plastic manifold. I have that problem and it packs up on my throttle body. Way back in time when I gumed up a couple of engines, I actually had gummy liquid dripping out of low spots in my piping. Out of ignorance, I built a glass jar into my piping to catch it. I guess the vapors went on into the engine where the water got boiled off and left the gooey tar which solidified when cooled and stuck things up. So first you have to decide if you are talking ‘‘tar’’ or '‘soot’.

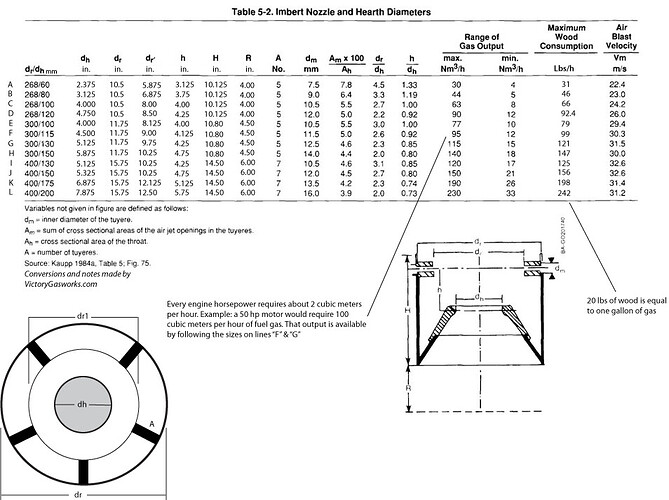

You asked if there was much difference between a Silverado and an S10. Yes. Lots heavier and a much bigger front end area, pushing more air. Which Imbert table are you looking at to get your dimentions? TomC

Hi Tom.

Hope you are right, but I’m unsure, think it’s sticky, and looks like chewing gum.

I use this, and think that the range of gas output is around 95 to 115 on my car, but as I said, I am a beginner at this.

Have looked at your thread, and am a little surprised that you have a throttle all the way down to the grate, does not that mean the gas flow maintains the speed all the way down, instead of opening up like a funnel and slowing down the gas.

But as I said, am a beginner and trying to learn all the time.

time running gasifier trying to get it to an operating temperature I am producing Tar that remains in system and it is still in the pipes and when I add heat it moves eventually it gets to intake manifold and valves . After doing this for over 5 years I am going to try to stop doing that to myself .