Early in my build, i was playing with a cone valve to achieve a more linear flow adjustment. I just couldnt fit it into the space i wanted it.

I use gate valves whenever possible. Please educate me about cone valves or other more linear options.

I talked to one of our experts at work a while back, he sayd one of the best designs is a type of a ball valve with a V opening in the ball instead of a round hole. Thats how he described it, l havent seen it in person. But for a DIY way l think a gate valve is your best bet.

Some update. I had a problem with the filter sack lately, the support cage in the sack collapsed and it shut off more thain half the sack, engine strugled to draw trugh it. I fixed it and cleaned the entire system, then went to work. Fast startup, but then the system run WAY too rich. I thod the reason is the automixer opened 100% and since the system is fresh and breathable, the opening in the valve is too small. But no, the plunger valve was allmost closed! What is going on???

Anyway, l had to drive on manual.

Hi Kristijan, if your air control valve or plunger valve was almost closed, I would be looking for a air leak on vaccum side of the canister that would pull the valve open. Also make sure the valve is not hanging up when it is operating on char/wood gas.

Can you show us some pictures of how you have the two vaccum lines off the canister hooked up to your air pipe line and char/wood gas pipe line going into your throttle body, to give us a better understanding on how it works?

My auto mixer air valve is piped into a separate twin port throttle body with the other side having the wood gas piped in, and both with a butterfly valves just ahead of it, controlling the volume of air/ gas flow equality. They have equal passage way openings to achieve this.

Bob

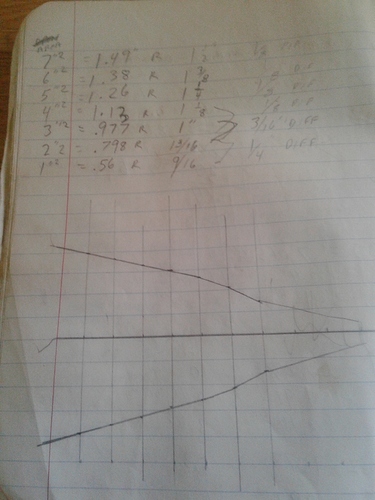

Bruce, I just made a cone shaped slug that would slide into a round opening to vary the open area. Here is a copy of the page from my scrapbook where I plotted out the shape. In actual practice I just made a smooth flat sided cone that was close enough.

Also kristijans mention of a b

I wish I had that feature on my truck.

If anyone is going to figure out the simplest way to do this auto mixer set up and make it work flawlessly, it will be You Kristijan.

Bob

Hi,

have you cosidered a “semi-auto-mixer”?

This was very often used in the WW2 systems.

Instead of regulating the air completely manually, the air valve was connected to the throttle. If the throttle was closed, the air valve was also nearly closed, if the throttle was opene, the air valve was open as well.

So the proprtions were closer to the ideal over a wide range.

But of course not ideal, so there was a second air valve which was controlled by the driver.

It was set for best power at full throttle and only controlled from time to time. So for WOT, there was best mixture and the link of the air valve to the throttle regulated the mixture for anything less than full throttle.

For sure not absolutely perfect, but since for only a partly pressed pedal not full power is needed a slightly off mixture is still ok.

Gives good results with a much less complicated mechanism than the autmixer, also less likely to have failures due to the membrane.

Have a look at the swedish book, if I remember right a good example is the Hesselmann mixer.

The Gohin-Poulenc as well, there are some pictures here: Admission d'air par tuyères

This just came to my mind as Kristijan and JO as well as Bruce and probably some other use air valves which are not linked to the throttle.

Maybe this can help to improve the mixer without going the full way to the automixer.

Kind regards,

Til

In the first picture ( drawing ) this appears to be an “up” draft mixer. Then the picture of it on an engine it looks like a “down” draft and everything is upside down and backwards to the first drawing. TomC

Huge thanks for this link for gas mixers. But I think we the automixer is VERY simple as Max conceived it and Chris S built it, and now Kristijan has made it even simpler by having it control a gate valve.

Rindert

Ha, l remember seeing those woodgas throtle bodys, never knew the reason why there are 2 flaps. Now it makes sence!

Well thats a ideal maridge of automatism and simplicity. I think l will go in that direction, thank you!

Oh, l found the reason behind bad performance with the automixer. A leak between the housing and membrane. Now the question is, fix the membrane and try again, or make a manual valve system with a “low throtle enrichment mechanism” as Til showed. Sugestions?

Kristijan, maybe a small (auxilliary or bypass) pipe with a solenoid valve that you could cut in or out with a switch, or even by a control that sensed RPM?. Kind of like Bob M. has done?

Hm…I’ve found very little reason to adjust air-mix depending on throttle position. Most of the time not needed at all.

However, differences in charbed restriction need to be compensated for. Starting off with a cold gasifier, ash and fines restricts the flow path and the air needs to be tightened. When the gasifier is warmed up the char clears up and the air valve can be opened up some.

My guess is this invention was used mostly to pull as much as possible on the gasifier at idle, not to make tar. @Til , you know the history. Could that be it?

Fix the membrane first and see how that works has my vote.

I agree with Don.

Bob

Hi Kristijan,

now that you are that far I would try to finish the “real” automixer.

@JO_Olsson, I guess you are right. I once read some hints for gasifier drivers from the wartime, suggesting to close the air valve for long idle periods or long downhill sections to keep the gasifier temp high with an overly rich mixture and thus more suction on the gasifier.

If it is really necessary? Well, here I miss some practical experience. I just noted the problem with Krisitijan’s lean mixture due to the fixed air valve with less than full throttle. Here it could help.

Hi Kristijan

you have an afr display on your car is not it?

Is this the probe

, lambda of origin, connected to a voltmetre?

I would like to install an afr on my truck without ruining myself. (the “afr” displays that I saw online are quite expensive ) Do you have any advice to give me about this?

in advance thank you

Thierry

JO, this makes sence.

Thierry, yes, l hooked a cheap 0-1000mv display on the original narrowband o2 sensor. Not ideal but it shows whats going on.

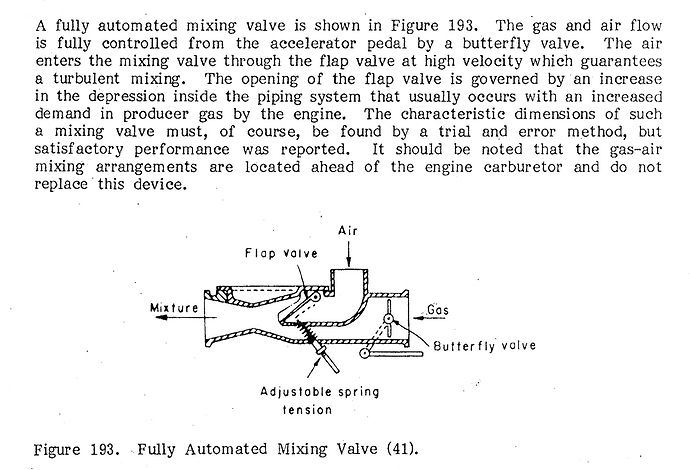

You all may be familiar with this, but I discovered it tonight while reading Small Scale Producer Engine Systems, and thought it might fit in with the discussion about auto-mixing valves a while back.

I book marked it to study on this some more. Looks promising.

Bob

Ok guys its been a while, time for a fast update. The MB had problems runing on petrol since winter. I culd not figure the cause. It started rough, if at all, run poorly, then just before US trip it died completely.

A couple of weeks after the trip l got back to it. I decided to check the whole fuel system and on emptying it, l found about half a galon of water in tank, pump and filter. Pump seized, but got it to run. I cleaned it all out, now it runs reasonably well, still not ideal. Water did damage standing in for a month.

How it got in, no idea. The fuel tank cap does not lock so an evil human being culd have something to do with it allso…

In order to pull out the fuel tank, l had to take out the gasifier and since out, l decided to do some minor modifications and today l was allmost done with them, when l noticed a design flaw burned a hole in the top part of te gasifier hearth. Its the only part not protected with cheramic wool and extreme heat got te best of it.

So after dealing with the fact l wasted half a day updating a broken gasifier, l decided to learn from the mistakes l made and make a new one. The hopper is still useable, and l am trying something l have been thinking for some time now, make the flute nozzle DOWNDRAFT gasifier. When l get the rigt pipe and some sheet steel, it shuld be a quick project.