Well damn me and the new year schnaps  yes! Blame the CO

yes! Blame the CO  This is the right one

This is the right one

As always a great job. Not being a chemist, is there a generic name for sodium silica? You actually soaked the Sodium Silica into the rock wool? One video I thought you showed just sprinkling it onto the rock wool. Is sodium silica water soluble? Apologizes for so many questions. TomC

Here its called glassy water or water glass. Its used as a binder in refractory cements.

Well its sold as as water solution here. The one l used was a wery concentrated one, if you leave a drop on open air it soon dryes or solidifies to a gelatinous mass and if you heat it strongly it popps up like a popcorn, interasting stuff.

Not sure if its the New years schnaps as JO wuld say, but l cant remember posting a video on sodium silicate before…

Yes l soaked the surface of the rockwool. I guess if l wuld soak tge entire plate things wuld be eaven better???

Very nice Kristijan Instead of a lot of questions like Tom C , I only have one. Wat size piping comes up from the filter to the engine? You sure can hide everything nicely.

Thank you Don.

This is 42mm plastic sewage pipeing. The fittings each have a seal and asemble like Legos. Fun stuff, cheap too.

Oh and l forgot to say l only use half the cooling rail now. Just the right side. This ment a lot less pipeing. The cooler is cool all the way eaven now. Charcoal IS amazeing!

You answered one of my questions. I really like your filter under the front of the car easy access to clean. What did you use for in side the filter bag and to hold it in place on the other side and not come off when operating?

Bob

One tip I have learned from the interweb: Foundry cores are made from sand mixed with sodium silicate, and they are hardened with CO2. Perhaps this would work on the insulation also.

Andy, have you got any idea how hardneing with CO2 looks like? And what kind of sand is used?

I have great interest in this sodium silicate bond insulations. A while back l posted a pic of perlitic flour l work with at my job. When my rockwool wears out, l will mix sodium silicate with this perlitic flour and see how it performs.

Kristijan,

Here is a straight-talking fellow who makes his own sodium-silicate, then makes refractory materials using that plus perlite and other common materials. Seems to work good. This is his YouTube channel:

https://www.youtube.com/channel/UCR4jAT1mvEwRRNo5qv8IewQ

and the sodium silicate:

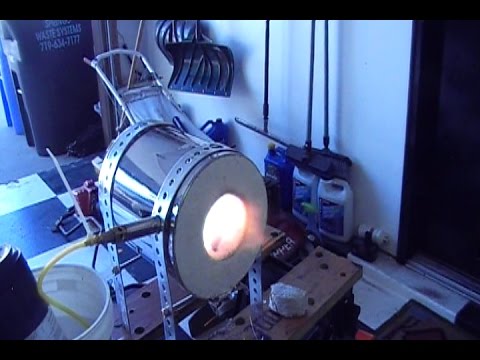

And his forge:

Merry Christmas and Happy New Year!

I don’t think it matters what kind of aggregate you use. Here is one video of many that covers the process. Another guy experiments with using baking soda and vinegar to make the co2

Kristijan, I’ve been re-watching your video and realized how much better the pictures were with the full screen. Did you get a different camera? Getting professional results. Might have to start charging admission! TomC

Tom, you are right, l use wifes camera now

I urgently neaded this:

This gets a hour woth of work with my old hand crank grinder done in a minute.

Now that’s not messing around!

With that much power and torque you could process a year’s worth of fuel in a day.

How much charcoal do you produce in a day of with heating house/greenhouse ECT.? I have electrical everything, for my home. I retort or fire pit to make charcoal not very efficient I know for charcoal making.

Bob

Garry, thats the plan! If l can bake enough

Bob, in my greenhouse, l can make at least about 80 pounds a day if l am free from work (2 lightups). However! The sistem now is a “smoldering” type retort, makes good char but leaves a terible chimney. It plugged shut from accumulated tar the other day. About a hour of hard core propane burning was neaded to burn the crap out.

Grinder is done, now its time for a bigger kiln.

My chimney in my outside boiler use to plug completely up with tar/creosote. I dropped my lit cutting torch down the chimney and got a little tar burning. Then I connected a 5 ft long copper pipe to my air line on the compressor. I blew air into the hot tar and things really burned. The water in the boiler would boil and over flow before I got all the tar burned into a crumbly material that came loose when I rattled a piece of log chain in the chimney.TomC

Now that sounds like a real show! I’m guessing your chimney was a piece of heavy wall pipe?

You’re going to be the sites’ leading charcoal producer at this rate. At least a competition between you and Ray. With the fines and dust you are going to be in a great situation to implement biochar.

You guessed correctly Garry. It is actually an old oxygen welding tank that was out dated and they would not fill it for me. I cut the ends off and it became the first part of my chimney. TomC

Kristijan, I know I’ve mentioned before, but I can’t help starting to wonder when you sleep. An endless stream of new equipment are leaving your production line and you still manage to attend to both family and work. Do you work in shifts with a twin brother?

Your new grinder is a real beast. I like it a lot. It will save time and effort for sure.