If chips and pellets pack to tight and normal chunks are to big, there is a Youtube of a gentleman who takes wood pallet slats and cuts them into about 5/4 or the thickness of the slat by 3/4 by 3’ pieces with an automatic machine he made with a Skill type saw. Then another Youtube the gentleman feeds these pieces into a tube that feeds them automatically into a table saw that produces squares about 3/4 in. TomC

I have cut 3/4" x 1" x 1" (approx) blocks and several other size cube like fuel and always had problems with bridging. I now use round branches 1" to 2 1/2" diam, cut them as long as the diam (ie. 2" diam piece 2" long, etc) and had much better luck with the feed. I still run my vibrator at regular intervals. Just as important for gas production is a regular shaking of the grate to keep the gas flowing through the char bed.

Pepe; I think round chunks are best. I have always run limbs chunked to length, but this summer a friend brought his band saw over and cut a couple of logs into 2x2 that I will chunk. I guess I will learn if square blocks are worse than rounds.---- if I ever get my truck back together. TomC

Hi, Chad R!

31.8.2017

2 sugar bits — ping-pong ball (— egg), is the natural scale in this power region.

Are you studying now, as no new questions are visibly formulated?

The “case” to calculate starts with a known motor, to be able to get the dimensions right.

Planning does not start from random metal pieces, but from the process the motor dictates!

After all, it’s good customer sevice to listen to the customer, and not push things the customer does not like ?

Hello Max, Thank you for the follow up, it is very appreciated! I have indeed been studying.

I have bought and been reading “handbook of biomass downdraft gasifier engine systems”, can you suggest any other reading material on the matter?

For my specific case, I have a small generator - 1200W - engine is very small, 98CC OHV

We live ‘off grid’ and we use this generator to supplement our battery bank and run fans when it

gets too warm in the house. I would love to have a gasifier capable of powering this small engine

but also be possible to (use larger restriction plate?) power a larger generator if needed.

I know this engine is very small, and I am worried that the size of a restriction needed would enable potential bridging issues.

As for fuel, we have large amounts of poplar saplings, from 1-3" in diameter. My plan is to ‘farm’ these wild grown poplar saplings and chunk them into gasser fuel… This will be a renewable resources for me as they grow fast and there is a large amount of them.

Any feedback would be appreciated. Thanks!

-Chad

Good want/need-to-use feed back ChadR.

Does this 98cc engine generate at 3000 or 3600 RPM?

Is it a four-stroke, or a two-stroke engine?

It would be much, much easier to woodgas with your stated poplar sapling bits to fuel a larger displacement four-stoke engine power down rated.

Easier will begin at ~212cc and top out for a single cylinder at ~390cc.

Past that then the smaller V-twin generators will be even another step-up woodgasing easier.

For verification of my claims read/study:

www.woodgas.nl MicroGasifiers

Regards

tree-farmer Steve unruh

Hi, Chad R!

1.9.2017

It seems that you are at the moment under the treshhold for selfgeneration of the energy needed to prepare the fuel by own “sources”.

The motor will only put out about 60% of the gasoline power.

If you intend to prepare for the comming wood handling for power and home-heating, you seem to need a “multipurpose” tractor.

It needs to have a mechanical power outlet to drive a chunker or rebak and circleblade for cutting.

Additionally a good hydraulic pump for driving a woodsplitter. The tractor brings home the wood and so on… Drying roofs and sun drying… off ground!

Preplanning for an enlargable gasifier goes the other way around: A bigger one needs inserts to satisfy a smaller process volume. The exchangeing process needs to be taken into account from the very beginning to avoid bad surprises.

Yes, Dutch John learned a lot during a few years back! And he has an excellent network of helpers, all you can dream of…

Hi, Alex!

2.9.2017

The guy in the wideo does not tell any specifics about the motor:

Displacement, RPM, LOAD!

His firetube seems to end into an OPEN basket of charcoal!

His restriction “throat” gives free radiation to the surrounding.

All these items makes it a floating guesswork where no calculations have a reference in reality!

A motor under full load makes it possible to estimate the gasflow.

Everything else is then possible to come to turns with…

In a working gasifier the process stages have to be interconnected in an uninterrupted row, without “pauses” and cooling zones, loosing the process heat by radiation and metal connection outward.

So, going backward:

The 5 KW generator is driven by a motor at what RPM, having what displacement?

Hi Steve,

Does this 98cc engine generate at 3000 or 3600 RPM?

Is it a four-stroke, or a two-stroke engine?

I am not sure the RPM of the engine, I can check the specs. It is indeed a four stroke.

It would be much, much easier to woodgas with your stated poplar sapling bits to fuel a larger

displacement four-stoke engine power down rated.

Easier will begin at ~212cc and top out for a single cylinder at ~390cc.

Past that then the smaller V-twin generators will be even another step-up woodgasing easier.

I do have another generator which is in the low 200CC range (it might even be 212CC), and I also

have a larger older briggs and Stratton 17HP from a riding lawn tractor (craftsman ls1000 if memory serves me).

I planned on using this engine (the 17hp briggs) to build a multifunction device - drive an alternator to charge my battery bank, run an air compressor when needed, drive a generator

head (somewhere around 3-4KW). If I were to build a gasifier to run this engine it would be

quite convenient and further my self sufficiency lifestyle.

I will gather real specs (CC/CI of engine, RPM, load, etc). In the meantime does this seem like

a decent candidate?

Thanks,

Chad

Hi Max!

It seems that you are at the moment under the treshhold for selfgeneration of the energy needed

to prepare the fuel by own “sources”.The motor will only put out about 60% of the gasoline power.

Ah yes this makes sense, and with such a low powered generator already, a 60% drop in power

would make it significantly less useful.

If you intend to prepare for the comming wood handling for power and home-heating, you

seem to need a “multipurpose” tractor.

It needs to have a mechanical power outlet to drive a chunker or rebak and circleblade for

cutting.

I have a John Deere 1010 RU with loader (has PTO), and also an old Farmall M with PTO.

I have seen a couple chunkers and it looks much easier than my current means. I will be

definitely building one of these as soon as I have some free time.

I do heat exclusively with wood already, do people normally use only branches/saplings/etc or is it common practice to also split to kindling sizes and then chunk?

Additionally a good hydraulic pump for driving a woodsplitter. The tractor brings home the

wood and so on… Drying roofs and sun drying… off ground!

Hmm I am embarrassed to admit I haven’t thought of using the tractor hydraulics to run a wood splitter. Another project on my list now!

Preplanning for an enlargable gasifier goes the other way around: A bigger one needs inserts

to satisfy a smaller process volume. The exchangeing process needs to be taken into account

from the very beginning to avoid bad surprises.

I would really love to have a gasifier which can handle different volume requirements… But is it

realistic? Could I build a gasifier to power a 17hp lawn tractor engine, and also power - say - my 1010? By the way, not really relevant however the FEMA gasifier paper used the same model tractor for its testbed - funny I thought. To clarify I do not intend to build a FEMA, I just thought it was interesting they used this tractor since it was rather rare.

Most “universal” are charcoal gasifiers. You can hook preety much anything on it, from 5hp to 100hp on the same setup.

As for wood gasifiers, a wk style gasifier allso can do similar, but to run optimal power/gas quality, you need to make restriction inserts that change the gasifiers internal dimensions. And adjustible sir nozzles (made out of drilled ss bolts-just screw in or out).

Empty the fuel hopper, vacuum out the char, change the restriction, add char back, hook on a different engine.

Hi, Chad R !

3.9.2017

“The motor will only put out about 60% of the gasoline power.”

Loosing 40%, producing 60% compared to gasoline output, putting it straight.

…

Your presented power scale spans now ~1:10 with the so far presented “motorpark”.

It seems (from a distance) to be rational to differentiate mobile and stationary setups.

With the stationary setup you have more flexibilities, and can use “spillheat” for water warming and space warming, drying, etc.

I imagine that the tractor installation gets priority, if you need wood home before the winter? (wood for next winter)

Using the tractor regularly makes scalable gasifier solutions less useful.

Scalability asks for concerns behind the nozzle-tips and outside the restrictions and height too! It is not a question of only the “inside circles”!!!

Hi, Chad R !

3.9.2017

While waiting:

John Deere 1,9 liter gasoline?

…’

L X n X 3 =

Nominal max consumption:

1,9 X 2,5 X 3 = 14,25 liter gas net/s

…’

Upper hearth volume:

14,25 liter X 0,05 = 0,7125 liter

…’

Restriction diameter:

0,01425 m3/s

_______________ = 0,007125 m2 = 71,25 cm2 ( square area )

2 m/s Square side = 8,4409715 cm

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::

71,25 cm2 X 4

_______________ = 90,718319 cm2

pii

( Circle area enlarged to have same

surface area as the nominal square)

:::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::

rootV90,718319 cm2 … = 9,5246164 cm ( circle diameter )

Restriction diameter … = 9,5246164 cm ~9,5 cm

:::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::

‘’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’

Nozzles: When temp available…

‘’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’

Hi, Chad R !

5.9. 2017

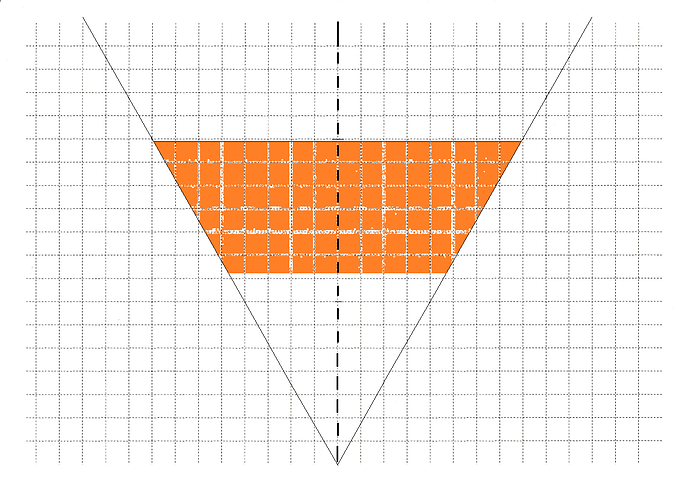

Process cone for the 0,7125 liter upper hearth

Each square is = 1cm =10 mm, so be sharp! 1/10 square = 1mm!

volume = 713,276 ccm. (for whole frustum cone!)

Hi, Chad R !

6.9.2017

The vertical draft in the upper end of the 0,7125 liter process frustum cone would be:

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::

First the area : Pii X (15,8 cm)2 : 4 = 196,06679 cm2 = (Upper end area)

equals = 0,019606679 m2

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::

The gas flow = 1,9 X 2,5 X 3 = 14,25 l/s

equals = 0,01425 m3/s

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::

Flow : area = velocity

0,01425 m3/s

__________________ = 0,7226796 m/s !!

0,019606679 m2

Which is a remarkably high value! (5% hearth!)

For fuel sizes between ping-pong ball and egg.

‘’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’

Nozzles: When temp available!

‘’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’

Hi, Chad R!

Is there a preference for preheating / no preheating?

Hi Max!

Wow, thank you for all the information. Apologies for the very delayed response, life has gotten busy (5 kids! :))

What would you recommend, to preheat? I assume it will be more efficient to preheat?

Hi, Chad!

16.7.2018

Long time, indeed!

Both primary air, around the hearth and a vertical plank heating the wood in the silo.

Then the exiting gas is pushing its heat through the wood in the silo, and the resulting steam is then condensing at the silo mantel.

The exiting gas around the hearth delivers heat to the primary air with a cyclone and by manteling; the more, the better.

Practical circumstances affect the choises…

Good examples are found in Jan-Ola Johanson’s Mazda build.

He does not use a plank, but the cyclone manteling is good.

PS: When I said “When temps available” I meant that correct calculations cannot be established without knowing the available temps!

Bless the tractor! (and the kids)