Oh yes , sleep is good. I am building a hotgas filter, will showcase it next week it is simple to build just looking for

Some wide banding for it. It will have a lot of filter surface area in a small package. It will be just right for your vehicle engine size and it will self clean maybe with just driving down the road vibrations off the car.

Bob

Oh you did decide for a hotfilter! Great. What medium will you use? Welding blanket?

Hope to see it soon!

I was thinking in a similar direction. Not a hot hot filter, but a semihot filter. Filter hot, dry gas trugh a big surface fine cloth, or eaven paper, while keeping it just cool enough not to damage the fabric/paper. Now, keeping the gas in the sweetspot (water boiling point temperature) is what l am working on.

Culd you give us some glimpse to your way?

My alarm will be screaming in 4.5 hours, but I can’t sleep. I’m thinking of your cooler tubes.

Why not let every tube go straight down to the common external gutter tube. One big single tube (or two medium) could then enter the lower part of the hopper from the gutter tube. That would save you some welding.

I’ll force myself to sleep now.

With a hot filter you don’t have to have the gas above or even near the boiling point do you? Just cool it then warm it up to the dew point for the amount of water that is still in after cooling.

I am thinking of pulling hot gas off between the cyclone and the cooling pipes. Just a little bit. My piping is all 3 in. dia. and I am thinking of pulling a 1 or 1 1/2 in pipe off this location. Then piping it down to the gas line that heads for the engine. About a foot or so from where the hot gas enters the engine supply line, I will put in a cloth type filter or paper truck air filter. The added hot gas will raise the temperature of the gas going to the engine so the filter will not plug with water, just soot or ash.TomC

Hey wake up!! I still be talking to ya!!

Yes you are correct it will be welding blanket on the outside, it will be folded in long length folds like bleated curtain around a rabbit double mesh screen cylinder. Two pieces for strength 1/8 " mesh, the diameter and length can be adjusted for what you need. I’m making cylinder bands to go inside the screen to keep it from clapsing from vacuum pressures. Fitted into a 5 gallon bucket with sealing lid. Using two pipe base flanges one on the inside of the bucket and one on the outside. The rabbit wire is cut and clapped to the pipe with theaded end and a flat bar goes inside the pipe and to the other side of the cylinder where the end is cut and folded closed and fasten to the flat bar. You just need to make sure there are no sharp pieces sticking out. I am going to cover it with wool and then put the welding blanket around it and clamp it to the pipe stove rope it close on the other end. Then the pleated welding blanket goes around that. Going to use it in my Charcoal Gasifier, can’t see why you can’t use it on your gasifier. If you need more filtering just double two bucket together bottom to bottom. And cut the hole in the bottom leaving a flange for bolting them together with sealant. Simple, it’s harder to write it all down.

I better let you guys sleep.

Bob

Yes Tom, the filter I am making will go after the gasifier or after the slyclone filter. And before the cooling rails.

What I like about it is there are no welding involved in making it. A three inch pipe would work great. I am using two inch pipe for mine.

On wood gasification, after the cooling rails is where you warm the gas through a mantle again for refilter through a paper filter. I have never tried this method yet.

Bob

JO, myne did to  first morning shift is about two months.

first morning shift is about two months.

Indeed, this is the way to go!

Tom, you mixed two systems! A hot filter is a sistem where you filter wery hot gas trugh a heat resistant material, then cool the clean gas. You talk about a reheat filtration where you cool the gas, condense it, then reheat just slightly to not clog the filter material.

I am goeing somewhere in between this time

Anyways, l am looking forward to your modifications!

Bob, sounds good! Be sure to find a tightly voven blanket. It sometimes likes to spread some knots when in operation after some time. Myne did this and it stoped operating as efficiantly after a while.

Hi back. Been gone two days getting fresh orchards picked year-long store-able apples, so reading to catch up a bit.

Good ideas interchanging guys.

KristijanK., three feed back thoughts

From the reading now your flex part has to have meant being able to use local/travel about sourced variable moisture fuel wood. Only reason why to try and be wringing out before the hearth fuel-wood moisture’s.

O.K. That is a worthy goal-set.

VARIABLE. It is a mistake to ever design around engine wide open throttle flows. An IC engine in electrical generating duty; or pumping use may only use at most, from a starting idle, to light loaded, to fully loaded 10 to 1 air-in-flow needs. Roads driving vehicle you must accommodate 20 to 1 variable air-in-flow needs.

Better to design for use at your average cruise air-in power needs. Then maybe you will have enough heat-loading to not have extended idle clean producing problems. Remember it has to do this winter and summer to be year around usable. WOT; if using a cruise average design will leave you produced gas short. Why Mr Wayne had now for a long time promoted hybrid fueling for these rare WOT occasions.

Keeping the system hybrid-fuel lets you fall back onto the original design fuel in needs-musts-demanded situations. Like mandatory inspections. Wife, driving injured you, to the hospital/clinic. Relative loan-outs; with you not then getting it back all gummed and tarred up.

Sounds like I’ve been there a time or two, eh.

tree-farmer Steve unruh

Hi, Steve!

7.10.2017

How convenient to choose, when all choices are at hand!

In a more restricted situation independence is a heavier factor.

Better carburettors have more than one nebulization nozzle…for a wide range of operation…

Already before WW II stationary gasifiers were equipped with different sets of nozzles for the occurring power need.

Much of this is already achieved with a “smallish” oxidation zone, and a well insulated “flexible” reduction zone.

WK has gone for the opposite solution. Partly inherited from FEMA and Imbert 1926.

At low motor power there is high vacuum available for strong blasting by groups of smaller nozzles.

Asking for cleaning vessels to stand against implosions!

Small maintaining nozzle groups at normal height and 1/3 height above restriction.

Full blowing nozzles at normal height. These are the only ones needing any maneuvering on/off. By rotary slide in the air distribution mantel.

Steve, apple purchase is planed for today, after work here too! There is a apple festival not far from here starting as l type…

Agree on what you sayd. Well, except the one thing.

Its a general rule to always make the gasifier on the small side for reasons you stated above. Have good idleing/low demand performance at a high price of sacrificeing the max power. I find room for improvement here.

My vision is since a gasifier has fixed turndown ratio, one needs 2 gasifiers to power low demand and max power demand. So. Why not use 2 gasifiers? I know Mike LaRosa did this but l am not interasted in hauling two machines to do a job of one.

What defines gasifier (lmbert) size?

-Nozzle height/circle. Not a problem, two plane nozzles are easyaly acheaved, likd Max sayd.

-reduction zone size. Not a problem in the grateless updraft style reduction l used on my alubox gasifier. It houses about 5gal of charcoal and while it runs a 1.6l engine fine, it culd as well run Waynes V10 if the oxy zone/restriction was bigger.

-and last, but not least at all, the restriction needs to be adjustible.

And voila, we got two or eaven 3 different gasifiers in one package.

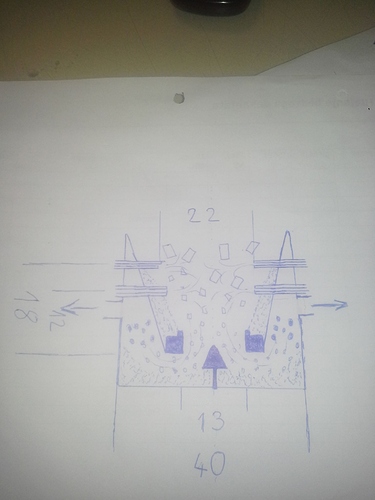

I have a skech showing what l mean, specialy the simple adjustible restriction but l can not upload the picture of it. My comp is dead and l for some reason cant upload stright from my android phone. But l did send it to @JO_Olsson a while back and if it is not too much to ask, wuld it be possible for you to post it here? You know, the one that has the cone in the restriction.

Thank you!

Well, the idea is to make the restriction wider thain usual, then, with a lathed ss cone adjust the restriction csa acrording tothe needs.

My new gasifier will be two nozzle plane and with possible upgrade to the adjustible restriction type, design rather similar to the skiz.

Hi, Kristijan!

7.10. 2017

I am shure your fast skizze does not show intended genuine avalanche 60* slopes…

Are you to have the upper nozzles as main nozzles?

Different nozzle-tip-circle diameters? (grand circles) (in the two levels)

I guess the regulation cone has to be ACID-proof to have any chance of withstanding a few test runs!

A compact copper cone covered by an acid-proof cone can last longer, if the acid-proof “hat” is machine-made and completely tight on the copper cone.

Alternatively, you can cast molten copper into the acid-proof cone…

the copper part reaching tightly (cylindrically) out of the bottom to get cooling air, or cooling water…

Hope you see something else than negative comments; the aim is to reach results!

Yes. Yes. No negativity intended.

You asked for feed-back. And your responses have clarified your goals and intentions well.

Ha! Ha! just me sometimes pushing more than a bit for designers to prioritize now for use by their female halves in their lives.

VesaM is the one that I’ve seen willing to side-step thermal idealism’s to get the maintenance points reduced; focuses into one area only; and operating systems female operator no more difficult than an old style manual choke carburetor system.

Smart practical women have been well able to operate wood cooking stoves and house heating wood fuel stoves since the beginning. I even know three local woman who do all of their firewood working up.

Yeah. Yeah. As long as “the man” does the grungy chimney cleanings.

Regards

tree-farmer Steve unruh

Hi, Kristijan!

7.10.2017

I was assuming my own comments as potentially negative, not comments made by anybody else, sorry Steve, I was only excusing myself!

Now for the “plunger valve” restriction.

If the upper part is a conical charcoal + ash “volcano” instead of whole metal, it would partly shield itself from the passing glowing gas and actively glowing char.

Only the outer edge is directly affected by the glowing gas. It can be made of acid-proof steel like a fence at the edge of the circular plate.

Another version is a wide 120* funnel facing the opening upward, and standing on a threaded shaft, screwable from below the gasifier bottom.

Ash in the threads… protected by a compressible metal hose around the threaded, graphite lubricated shaft.

The funnel filled with ash and passive char, radiating downwards.

Funnel diameter ~2/3 of the restriction…

No negativity! If l thod my ideas are perfect l wuld never post them here in search of opinion. I hope you guys put as mutch question marks as possible to my ideas, becouse that way you help me a lot with findinding the fragile boundry betwen good snd bad ideas.

Max,

Correct. This skizz is just a skizz. My current gasifier has those details taken care of. The ashcone will have plenty of place to build.

No, the main nozzles will be the bottom ones. They will have preheated air, while the top ones will be auqilary ones (in case of extreme gas demands) with no air preheat.

The nozzle circle will follow the 60° ashcone.

I have no dubt the ss restriction cone will survive the heat. Or at least shuld… But l agree, a quatity aloy shuld be used. Nevertheless, we are talking about some mass hete. The cone culd easyaly weight a kilo.

The massive cones shape is allso partly planned for flywheel effect at idleing.

As for useing copper, yes, it wuld work if the cone were open at one side, able to radiate out the heat. Since this is unwanted and it is actualy desireabe to have the cone well insulated with char/ash, l think the copper wuld just melt.

The ash insulated plunger is a good idea! It might work.

Or maybee eaven cheramic?

Steve,

What you speak of is the only reason why l built the automixer on my Chevy.

Women call for equality these days. Ok, l have no problem cooking, cleaning, child careing and stuff like that. But, in the meantime l allso expect my wife to help me prepare firewood, take care of the fealds, the animals, and ofcorse, drive on wood. We had such policy from when we met and it works fine for us.

But like you sayd, the genders will never realy be equal. Eaven if my wife wuld want, she culd never withstand a 9 hour firewood preparation job, or strike a 20 pound hammer at a pole with one hand… not built for that.

Kristijan, I would very much like to come and see how you manage such fast progress. Yet I know you have several other irons in the forge. I try to squeeze in an hour two almost every day but I’m still working on my cyclone/heatex. Welded a bunch of fins and the outlet in place today.

JO, I think Kristijan has a twin brother, that he hasn’t told us about. Ha ha. Amazing how quick things get built. Good job @KristijanL on your gasifier project. Looking forward to see it run and going down the road.

I must be spending to much time thinking what I am going to do next. But I hate making mistakes. Like everyone else.

Bob

I would like to see him in action as well. He’s worn out a couple of gasifiers to my none…

Bryan