Well if actually “free” then get it.

Fossil coal chunks can be woodstoved with care. And unlike wood, will store forever. No bugs or microbes will be eating it.

You can then use it for experimental trialing on many things.

Regards

tree-farmer Steve unruh

free is always a hard one for me to turn down . I vote yes

I’ve seen Anthracite (hard stuff) listed as good gasifier fuel in old publications and read somewhere that it was the preferred fuel for British charcoal gasifiers during WWII. I haven’t tried it in mine yet, but assume that the higher density of the coal will give a much longer driving time between refills. Maybe a bit harder on the filters.

The soft coal is high in sulfur and yields some corrosive sulfuric acid in the gas.

From Wikipedia:

Anthracite is a hard, compact variety of coal that has a submetallic luster. It has the highest carbon content, the fewest impurities, and the highest energy density of all types of coal except for graphite.

Anthracite is the most metamorphosed type of coal (but still represents low-grade metamorphism), in which the carbon content is between 92% and 98%.[1][2] The term is applied to those varieties of coal which do not give off tarry or other hydrocarbon vapours when heated below their point of ignition.[3] Anthracite ignites with difficulty and burns with a short, blue, and smokeless flame.

Anthracite is categorized into standard grade, which is used mainly in power generation, and high grade (HG) and ultra high grade (UHG), the principal uses of which are in the metallurgy sector. Anthracite accounts for about 1% of global coal reserves,[4] and is mined in only a few countries around the world. China accounts for the majority of global production; other producers are Russia, Ukraine, North Korea, South Africa, Vietnam, the UK, Australia, Canada and the US. Total production in 2010 was 670 million tons.[5]

Anthracite is similar in appearance to the mineraloid jet and is sometimes used as a jet imitation.

Anthracite differs from ordinary bituminous coal by its greater hardness (2.75–3 on the Mohs scale[9]), its higher relative density of 1.3–1.4, and luster, which is often semi-metallic with a mildly brown reflection. It contains a high percentage of fixed carbon and a low percentage of volatile matter. It is also free from included soft or fibrous notches and does not soil the fingers when rubbed.[3] Anthracitization is the transformation of bituminous coal into anthracite.

The moisture content of fresh-mined anthracite generally is less than 15 percent. The heat content of anthracite ranges from 22 to 28 million Btu per short ton (26 to 33 MJ/kg) on a moist, mineral-matter-free basis. The heat content of anthracite coal consumed in the United States averages 25 million Btu/ton (29 MJ/kg), on the as-received basis (i.e., containing both inherent moisture and mineral matter). Since the 1980s, anthracite refuse or mine waste has been used for coal power generation in a form of recycling. The practice known as reclamation is being applied to culm piles antedating laws requiring mine owners to restore lands to their approximate original condition.

Chemically, anthracite may be considered as a transition stage between ordinary bituminous coal and graphite, produced by the more or less complete elimination of the volatile constituents of the former, and it is found most abundantly in areas that have been subjected to considerable stresses and pressures, such as the flanks of great mountain ranges.[3] Anthracite is associated with strongly deformed sedimentary rocks that were subjected to higher pressures and temperatures (but short of metamorphic conditions) just as bituminous coal is generally associated with less deformed or flat-lying sedimentary rocks. For example, the compressed layers of anthracite that are deep mined in the folded Ridge and Valley Province of the Appalachian Mountains of the Coal Region of East-central Pennsylvania are extensions of the same layers of bituminous coal that are mined on the generally flat lying and undeformed sedimentary rocks further west on the Allegheny Plateau of Kentucky and West Virginia, Eastern Ohio, and Western Pennsylvania. In the same way the anthracite region of South Wales is confined to the contorted portion west of Swansea and Llanelli, the central and eastern portions producing steam coal, coking coal and domestic house coals.[10]

Structurally, anthracite shows some alteration by the development of secondary divisional planes and fissures so that the original stratification lines are not always easily seen. The thermal conductivity is also higher; a lump of anthracite feels perceptibly colder when held in the warm hand than a similar lump of bituminous coal at the same temperature. The chemical composition of some typical anthracites is given in the article coal.[3]

Anthracite has a history of use in blast furnaces for iron smelting; however, it lacked the pore space of metallurgical coke, which eventually replaced anthracite.[11]

Good find on that article Abner. If that is Anthracite that Kristijan can get and make it work in his gasifier, he would only have to fill his hopper once a month

Sorry for geting back so late to you guys on the coal topic, l was buissy. Unfortunaly someone beet me to the deal, but based on what you sayd it wuld be nice to mix with wood. I like Dons thinking particulary

Anyways, look at the following video and you will see a familiar lemon-neaded grin. https://www.youtube.com/watch?v=9XpnOgmKEfc&feature=youtube_gdata_player

Had a first family DOW ride with the Mercedes! Thats it for now, details will folow. BBB!

Aaah! Finally! I’ve been waiting patiently all weekend for your trip report

We want to know everything. Power, hopper juice collecting and every other performance data. Also I don’t think we have seen a proper walk around of the finished system.

Report in a few words, there are flaws to be corrected. The gasifier seems to be spot on regarding to size, as the engine idles great at 600rpm and l managed to put 110kmh (68mph) out of it. There are still reserves.

The cyclone baffle works great! So do the wet cyclones, extracting a liter of sooty water every hopper worth of wood.

All l can say is the engine realy likes woodgas.

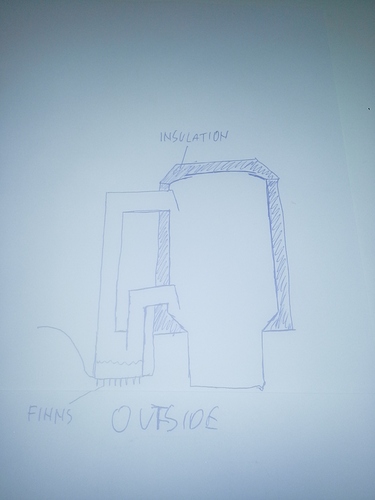

Now, the flaws. Hopper condensation. Went the monorator way with lots of finns on the hopper. A mantel around the finns and a strong fan pulling air trugh. For some reason, this was inneffective! So, we think forward! I hope to get a walkaround today.

Thanks for the ride in the Mercedes . Very nice

Ok l found a way to upload the pictures via smartphone so here it goes!

(/uploads/default/original/3X/a/1/a144c3376e0ef894f85412422eed594a58f157ldf.jpg)

There is a mantel around the hopper (not shown on the pics) and the fan pulls air pass the finned hopper for condensation, but this has shown to be ineffectible.

This is what l am thinking now

The condense tank in this design is the the main cooling/condenseing area. The tank wuld sit where the fan is positioned now, protrudeing trugh the bottom for the air stream to cool.

Any thods?

Hi, Kristijan!

1.11.2017

Provided you get a larger cooling area than you had on the silo itself!

Because cooling = condensing… now with streaming “speed-wind”, I hope.

Can you divide the the cooling “package” in 3 or 4 parallel flat boxes with “speed-wind” in between them?

Hi Max!

I see what you mean. Yes this wuld be possible.

The question mark here is will there be sufficiant steam circulation to drive this condensor? Afterall, the cold gas has to go back up about 25cm…

Hi, Kristijan!

1.11.2017

Isn’t it still a fan-driven loop between the silo and the “cooling-battery”?

If the cooler is below the silo, you will not get any thermosiphone circulation!

No. The idea is for it to work as a wk pipe, only difference is the majority of the steam wuld dondense in the actual condense tank.

Yes those are my fears.

Hi , Kristijan!

1.11.2017

You need to have the cooler on equal hight or higher to get ANY thermosiphone circulation!

Otherwise, the electrical fan (with very tight shaft-feedthrough!) will give you full freedom to go below the trunk bottom!

Put the fan on the cool return leg blowing upward; more tar on it, putting it on the hot leg may overheat the fan-motor, if it is not cooled well.

Hmm the fan idea is logical but the tar! It wuld be hard to acheave a good seal on the shaft minus locking it cold, and allso the tar buildup on the impelers wuld be problematic.

You think the higher lengh of the upper siphone wuldnt drive the steam down?

Hi, Kristijan!

1.11.2017

Now you are on! I was afraid you thought that i suggested outside "fanning!..

Having the impeller in the hot down flowing leg makes less tar on it, and putting it in the cool return leg condenses more tar on it.

In this system the fan can be minimized, by having only 2 - 4 wings on it; as it has to do very little pressure difference, just moving the distillation gases around…

A prolonged shaft between the motor and the impeller protects the motor fully, if it is in the cool air streem.

The impeller can have “outside the shell” doubble bearings, unaffected by the tar…

Ok so the first plan is try to diagnose exactly why the monorator didnt work. If the monorator hopper can mot be made to work, l will try this sistem and if the thermosiphobe doesent establish, make s small fan. Good.