Well, I think I am going to start designing and building a outdoor wood boiler that uses gasification tech. If anyone had built one or has any good ideas please pass them along! Also, do anyone have easy to use software that a tough design can be generated on? Something like CAD? I plan on using the unit to heat my house, my barn, and my pool.

My biggest advice is one word.“KISS”. Keep It Simple Stupid. I built one and the fire box was very complicated and required a lot of welding. The only way I could test the welds was to weld the fire box into the water container, fill the container to about 7 psi of air then crawl into the fire box and spray soapy water around, mark the leaks, then let it dry and weld. I spent 3 months inside welding. ( light bulbs brake when a welding spark hits them)

I suggest you use a round water tank and a ROUND fire box to eliminate some welds. You are going to have a lot of welding to the bottom where you are going to be pulling the gases.This is like building a wood gas vehicle— NO AIR ( water) LEAKS ARE TOLERATED!!!TomC

Yes, simple is good. I would suggest welding only a small volume tube heatex and pipe the hot water into a larger storage tank. We all know tary gases in contact with a cold surface will make a mess. The trick is to keep combustion in a hot enviroment (firebrick or cast iron), only clean hot exhaust heating the heatex tubes. And then keeping the heatex water near boiling temp through the whole burn keeps the exhaust above dew point - no rust, no mess, easy cleaning - efficient long life heatex.

I built a boiler, but not really a gasifier type. I echo what tom said about the round firebox. Flame plays all around on the upper surfaces for good heat transfer. I used a large water tank for the firebox and pressure tested it before I cut the door end off. saves the inside welding.

Hi Joseph, I have these youtube addresses that may help you. I have build two pre-projects until now; the best help I had was from Gabriel M. Apostol´s devices and I build my second one with his model and it worked mighty fine. It,s a a matter of combining wodgas generator to the burn chamber and from there on. I’m trynig on this pass. As TomC said:

I think that,s the way to go is to take it calm. My project has beeing goin on for about 3 years now, do to my job as a phisician and this takes most of my time (I also hace a wife, this takes time also). I´ll try to post some pictures of what I did up till now, This are the links:

https://www.youtube.com/user/ApostolEngineering/videos

https://www.youtube.com/channel/UCBg4kZhd0J4QebBQ7osadMg

Abner

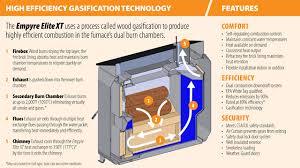

can anyone tell me what the path of the combustion air is that most of these modern “gasification” units are using? Is the air restricted in the burn box and then introduced into the hot gas for it to flash or is it just pushed through the burn box and acts as a simple downdraft gasifier? Seems like a lot of air is moving through the firebox resulting in complete combustion.

HI joeph hauler I will sujest that you find some models is varius stores too compare designs,then build accordingly. Allthough i will try to explain my friends new gasifier boiler type system, It seems fairly simple actually ,The fire box is on the top with no exoust exit,there is a small fan like about 50 watts bolted too the door,it blows air in too heat things up,then when heat is reached it shuts down too save wood.when the fan is on since the exoust goes out the bottom of the burn box, out about a 1 1/2 " by 8 " slot,then the exoust after going out the bottom slot in the fire box hits a fire brick with groove in brick too catch exoust and that brick turns red , as that is whare the flare is happening for extra gasification,and whare the most extra heat is produced.after the flare leaves the bottom fire brick under the burn box,the exoust is pushed with the little 50 watt fan out too the back wall of the furnus,just behind the burn box, allso in the space that the exoust gas is moveing up the back wall of boiler,there are several pipe that hold the water too heat up,The pipe are only about two " diameter and about 4 feet long,then the water is then transfered too a 250 or in his case a 500 gallon water tank for storege,the tank is well insulated and the entire unit is in a big shed well insulated,for wood storege,and unit insulation.The unit runs about 2500 degrees at the fire brick area, about 1000 degrees hoter than old fashion wood boilers.The inside is mostlly fire brick other than the pipe radiator on the back wall.while the unit is getting a fire going,there is a swing plate that opens,too let exoust out like convetional wood burner ,strait up and out the chimney pipe,then when is is going good door is shut too start heating by fan forseing the exoust out bottom too flare on fire brick then out back wall and up around pipe radiator and out top of the back wall chimney.Hope this helps,this is just one design,i haven’t seen any different boilers yet myself.I am thinking on building ONE ALLSO,If i could draw it might be easyer,let me know if need drawing,i could snap a picture and upload. He claims he uses way less wood than his old conventional non gasification boiler that the controlls stoped working on,and had a crack in the tank too hard too reach too fix.as with all wood boilers the water level must be checked when cold or tank or radiator cracking will happen over time.PS the whole gasifier boiler is not much bigger than a standard 200.000 BTU natural gas furnus.Plus the water tank.

Thanks Kevin, it makes sense now where the air goes. I think a little pre heating of the combustion air will help efficiency along as well. I think that I can build this pretty easily for around 3500 bucks… That is using good 1/4 inch thick boiler plate for the fire box and 316 stainless for the heat exchnger/water tank. (just priced out material on Alro) Gasification units will increase burning length by 50%!!! And, it also reduces emissions.

Yes the emisions are far less or practically no smoke one heated up good useing dry wood ,the only draw back is stacking and drying the wood ,or stacking one year ahead,so wood is nice and dry.The stove i looked at was mostly fire brick inside,probbly 3/16" plate behind fire brick wood work good.i think you could DIY fire brick and the pipe radiator eliminates the big water tank effect,witch keeps flame hotter and dryer till it hits the radiator.

Here is a simular fuel flow,the firebrick block would be on bottom area,the pipe radiator would be in the back blue area,the little fan in the door has enough power too move the flare gas,the only ash is on top the notched fire block,far less ash.I think i would put an extra clean out door on the bottom too pull the pipe radiator out the bottom for repairs or replace,if needed,and possibly a clean out door on top over the pipe radiator in case it needed cleaning from burning greener than should have wood.Depending ware your chimney exit attaches.The heat exiting the chimney is down too about 300 degrees,so not much heat loss considering it was 2500 3 feet away. The water storage tank sits away from the heating unit,and the water in the tank continually circulates through the pipe radiator,if for any reason the pump shuts off a sensor could shut the fan in the door off too shut the heat off until pump is moving water through pipe radiator again.PS The notch in the fire block on bottom causes the the flare gas and heat soak into the block and bounces toward the ash clean out and then towards the blue area, fan in door is behind the tin cover on the model i seen all-so.These design burners have no grate,not needed.

I wonder if we could put the water storage tank inside the unit and use the top space for it? Then we would be sucking some of the heat from the primary burn off to keep the storage “warm” while the secondary gasses heat the water coming through the tube back from the house (return line)

The only problem with the tank that close to the wood burn area,is the effect of the extra moisture cooling the flame ,and maybe loosing the cleaner burn. The old barrow inside a barrow was the old style.my burner is a ashfault roller inside a water tank i welded together,it works but it really is the smokey type, they just dont put the hotter flame out for cleanner chimney effect,as they are all ways much cooler running,than the gasifier type.Putting the burner and water tank inside a small shed well insulated will work good.

Good point. plus 20 letters

I dont know what mix they used for the bottom fire block that the gas flame is blasted at,but the block glows red too aid in the combustion process,and heat recovery.

Yeah, I know what you are talking about

Got too get some wood for my water log burner tomaro for a while,later on ideas.Nap time over and out.

Joe

Have you come up with a design yet? I’m tossing around different things in my head to add supplemental heat to my house just started looking at OWB

This design burns for 1 1/2 hours to heat your house for 24 hours by inducing a power vent at the back of the exhaust during combustion. Won’t smoke out your neighbors. http://www.garn.com/

It will be a 3 pass boiler I may put an additional all copper loop inside that will be used for hot water. (showers, dishwasher, washer, pool)

I have to look more into that Garn Doug D. Interesting stuff.

Edit, Looks like it uses a large capacity water jacket.