E’ passato molto tempo da quando scrivevo su questo forum. Ho aperto questo thread con l’obiettivo di non dare disegni ma fornire informazioni affinchè uno stimolo mentale venga trovato e spero che i moderatori del forum condivideranno questo mio pensiero. Scriverò sia in italiano , la mia lingua madre, che in inglese affinchè tutti possano leggere e riflettere. In questo thread voglio proporre un nuovo concetto sia per produrre ed utilizzare la carbonella che per produrre energia elettrica senza creare gas combustibile. In tutti i design per i gassificatori a carbonella vedo che utilizzate la carbonella ma nessuno utilizza il legno… come tutti sapete per produrre la carbonella occorre pirolizzare il legno; in questa fase sono rilasciati char, co2 etc… Per quale motivo non si converte direttamente il legno in carbonella all’interno del reattore sfruttando cosi tutta l’energia termica che può rilasciare il legno? Inoltre… perchè continuare a creare gas combustibile a basso contenuto energetico per azionare un motore endotermico con scarso rendimento termico? A questo punto vi chiederete che non solo non ho scritto per molto tempo sul vostro forum ma che sono diventato anche matto

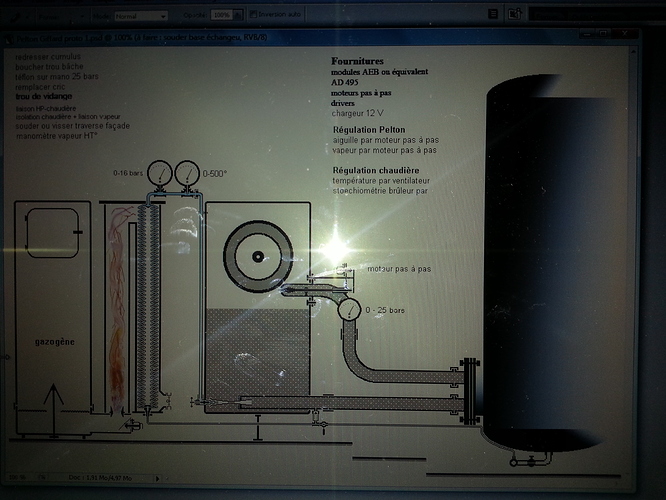

Quello che voglio dire è che dobbiamo fare un passo indietro nel tempo. Prima della creazione del motore endotermico veniva utilizzato il vapore come forza motrice. Ovviamente il vapore ha un rendimento limitato dovuto al suo stato di gas che lo rende comprimibile e quindi con basso rendimento. Nell’anno 1852 un ingegnere francese chiamato Henri Giffard ha creato un particolare iniettore che utilizzava lo stesso vapore prodotto dalla caldaia per mettere sotto pressione l’acqua per rimettere acqua nella caldaia. Andando ad analizzare la costruzione dell’iniettore (senza pistoni) e che la pressione necessaria al’acqua per vincere la pressione del vapore della caldaia deve essere maggiore come può essere possibile che funzioni? Per la nostra fisica se ho una pressione di vapore di 6 bar non posso ottenere una pressione maggiore anche di diversi bar oltremodo effettuo una conversione da vapore a acqua. Quindi all’interno di questo magico iniettore deve accadere qualcosa. Ma valutiamo un altro fattore… se creo vapore e con lo stesso metto sotto pressione l’acqua incremento il mio rendimento energetico finale, passando da uno stato gassoso e quindi elastico del vapore ad uno stato liquido e quindi incomprimibile come è l’acqua. Tutto questo ragionamento porta alla considerazione che si possa creare un generatore idroelettrico artificiale con l’iniettore giffard utilizzando il vapore come vettore energetico partendo dal pellet di legno come energia iniziale. Tutte queste considerazioni dovrebbero fare pensare…

It’s been a long time since I was writing on this forum. I opened this thread with the goal of not giving drawings but providing information for a mental stimulus to be found and I hope that the moderators of the forum will share my thoughts . I will write both in Italian, my mother tongue, and in English so that everyone can read and reflect. In this thread I want to propose a new concept both to produce and use charcoal and to produce electricity without creating combustible gas. In all charcoal gasifier designs I see that you use charcoal but nobody uses wood … as you all know to make charcoal it is necessary to pyrolize the wood; in this phase, char, co2, etc. are released. Why is it not possible to convert carbonella wood directly into the reactor, thus exploiting all the thermal energy that can release the wood? Moreover … why continue to create low-energy fuel gas to drive an endothermic engine with poor thermal efficiency? At this point you will ask that not only did I not write for a long time on your forum but that I also became crazy

What I want to say is that we have to take a step back in time. Before the creation of the endothermic engine, steam was used as a driving force. Obviously the steam has a limited efficiency due to its state of gas which makes it compressible and therefore with low efficiency. In the year 1852 a French engineer named Henri Giffard created a particular injector that used the same steam produced by the boiler to put the water under pressure to put water back into the boiler. Going to analyze the construction of the injector (without pistons) and that the pressure necessary to water to overcome the steam pressure of the boiler must be greater than it may be possible that it works? For our physics if I have a steam pressure of 6 bar I can not get a higher pressure even of different bars respect to input and I also make a conversion from steam to water. So something must happen inside this magic injector. But let’s evaluate another factor … if I create steam and put with the same the water under pressure I increases my final energy yield, passing from a gaseous and then elastic state of vapor to a liquid state and therefore incompressible as water. All this reasoning leads to the consideration that an artificial hydroelectric generator can be created with the giffard injector using steam as an energetic vector starting from the wood pellet as initial energy. All these considerations should make you think …