I think it will melt,

Perhaps placing a “saddle” of high grog ceramic clay over the top of the pipe with holes for air flow? Maybe some aluminium power supply heat sink material fastened to both outside ends to carry off the heat? Or run the ends through a container of water?

I have been experimenting with a mixture of plaster of paris + perlite + crushed glass (cullet) as a cover for some high powered TLUD stoves. It might be able to take 1200 degrees F when directly exposed to flame, so I have shielded it with steel. So far, I have done ten cooking sessions, about a dozen hours. I see no damage whatsoever. Next, I will order some castable refractory. I bought a bag of it about 35 years ago and made a charcoal powered aluminium foundry to melt down old automobile and aircraft pistons. Now I cannot find that bag (if I didn’t use it all), so guess I’ll order some more.

OK, I got everything put together and ready to fire up tomorrow. We will see.

Ha thats a bald test indeed

My thinking is it will hold well when the gasifier will operate, but when there will be no more air passing trugh it at cooldowns it will just melt.

For what it’s worth, In the early days of my wg experimentation, I had a frying pan I thought to use for the grate. I wasn’t sure if it was aluminum or stainless, so put the cutting torch to it. It didn’t melt so went ahead and drilled holes in it and all. Seemed soft drilling so I went at it again more seriously with the torch at one of the holes and sure enough, melted away. Seems like the chrome plating on it distributed the heat enough to keep it from melting.

Maybe if you had a thin tube of stainless and poured it full of aluminum?

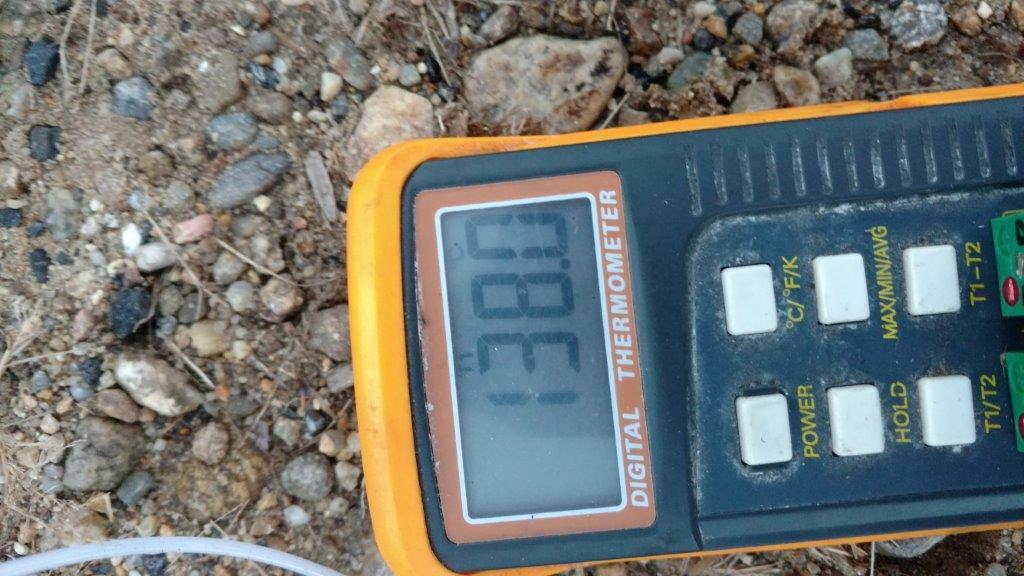

Aluminum Nozzle Melted at 1400 C

I set up to run at 4" w.c.

It only took one minute to get a sustained flare.

Looking down the aluminum throat is pretty.

You can see the thermocouple with the business end right under the nozzle holes.

At about 10 minutes into the burn and 1250 C I saw a drip forming and thought that was the aluminum melting, I pulled out the drip with my poker and discovered that it was iron. A nail had reached the reaction zone, melted and dripped through one of the the nozzle holes. At this temp the aluminum was still solid and the aluminum outside of the barrel was running around 350 C,

At 1380 C I saw a shower of sparks coming down through the nozzle holes. Sparks looked like a 4th of July sparkler. I checked with the poker and the aluminum was soft. Moments later the temp passed 1400C and the aluminum collapsed.

I’ll send a picture of the nasty results when everything cools down.

So I think that this thick walled aluminum tube might work below 1200 C. It may be better to keep things down around 1000 anyway to avoid creating abrasive and nozzle obstructing clinkers.

Copper is a better conductor, melts at a higher temperature and is physically more durable. It is the preferred tuyere for ancient and modern smelters and a good choice for a gasifier if it wasn’t so expensive.

Kristijan’s thick-walled steel pipe looks pretty attractive and Dave gets 100 hours out of a simple pipe cast into a block of refractory. Maybe Andy’s idea of aluminum filled stainless would transfer enough heat away to slow the oxidation of the stainless while it protects the aluminum from direct heat?

Thanks for the warnings/guesses. I needed to see it for myself.

I’m pretty impressed with those results, since aluminum is supposed to melt around 660 C (1220 F).

Further thought on my suggestion of aluminum poured into a stainless pipe doesn’t sound so good. the aluminum will shrink on cooling and be loose in the pipe. That won’t work. Perhaps if you plated the cooled alu pipe, but thats beyond home workshop.

Well tested Bruce , I guess unless we try we never know , that’s one for the tick, done box .

Kristijan’s thick walled pipe worked so well for him that , I will be going down that route , once I have used up my ceramic nozzles and shall build a new tank just for that .

Dave

I can’t give so much  as i wished…my keyboard would be ruined…

as i wished…my keyboard would be ruined…

Great testing and even greater results…

bear in mind, older guy’s, most probably tried at home, to cook an egg in a paper bag over an open fire…

why does it work?

The double ended pipe is a great experimental idea… could blow cold air in at one side and the warm air coming the other side to heat up some other stuff…

The passing cold air would be sufficient to keep the nozzle in temperature range…

Very usefull experiment… Thumbs Up all the way…

I nickel plated a copper nozzle, but the plating cracked and peeled. I have yet to see any degrading of my copper nozzles.

The double ended pipe also allows water to flow through. Does anyone anticipate a problem if we set the water flow for maximum load then let excess water or steam flow through when engine is idling?

This was the primary reason l stoped adding water. Its hard to meter. Nothing l tryed was reliable enough.

Hi Kristijan,

I use infuse drips, they are accurate and easy to adjust. The only thing, not a problem here, is to use mineral free water ( osmose).

once adjusted, drips per minute, then i have a electric valve to open or close.

On my trike, the drip/ excess water steam, can pass by, so in case of this going thru tube, might work very well without problem

Less vacuum is less heat = less water vapor. a kind of selfbalancing act…

What will happen if I drip water in one end of the tube so that water (or steam) comes out of the other end? Will the reaction still run away and melt my nozzle? Will the reaction temperature cool down below 900 C and stall the reaction? Is EGR the only way to keep the reaction temperature below 1200 C under engine load?

Hi Bruce , when I had a play with a stainless tube with a few holes on the top and blanked off on the end , when I dripped water into the tube it would flow towards the holes as my tank was on a lean , I could see most the water turn to steam almost straight away and get sucked up through the 2 small holes in the pipe , after a while I increased the water drip and it started puddling till that too evaporated into steam, all the extra water just back filled the pipe and came out the end it was dripping into , if you know what I mean .

So I should imagine with your set up as long as you have a slight slope on the pipe it would run off any excess water out the other end and maybe just cool the pipe down to a level where maybe only a certain amount of steam would be created .

Dave

Dave, how about using a bigger pipe and have it blocked off on the ends on the bottom so the water could puddle across the pipe. If the pipe tilts from vehicle movements going down the road or turning corners the water would not all run out. The water would then keep the pipe cool and also make steam. Cold air and water drip in one end and air/exhaust in the other end.

Bob

Hi Bruce, I’ve been out of touch a while and then my computer hard drive went down. Anyhow, I just picked up this thread yesterday and was reading down through where you were thinking about an aluminum pipe/nozzle like the copper one you have. My thought was “no way, it will melt” as you also found out. On to your question of using an open ended copper pipe and just letting a small stream of water run through it. ,This will work, but be prepared to condense out the excess water you will find in the chargas leaving the gasifier. Some of the water you add will be converted to H2 and CO, but not all of it, Especially if your engine is idling or there is a lot of humidity in the air. I put a cooler on my Ford Ranger expressly to condense water out of my chargas stream. Have you (or anyone else) tinkered with a water cooled nozzle? I played around with one several weeks ago and the initial results are promising. More on that when I have had a chance to put it to a more extreme test.

Gary in PA

Hi Gary,

Great to hear from you. I assume you recognize your handiwork in my pictures.

I can see how sending water or steam into a horizontal nozzle with a single air inlet would overload the reactor since there is no place for the water to go but into the charcoal. I can also see that a steam filled nozzle might introduce too much steam and not enough air to keep the reaction zone hot at idle. However on a recent run with the MG I cranked the water mister up pretty high. When I got back home water was dripping out the other end of my double inlet nozzle. The performance seemed no different than with a slower water feed and the inside of my cooler/condenser was dry. On my maiden voyage Icaptured a few ounces of condensation in my cooler, but none with my later run with higher water flow. I assume the condensation in the first run was from the moisture in the charcoal that had been exposed to humid air for several months. I also assume that the reaction zone was able to eat all the steam generated by the excessive water mist. I don’t have enough experience to be sure about these assumptions.

I can’t wait to hear more about your water-cooled nozzle.

The aluminum was holding up well at over 2000 F, so I still think AL has potential with water or EGR.

How about this: An aluminum bar passing through the reactor with two holes bored through the length, one for reaction air and one for cooling water?

I too, had wondered about a water cooled nozzle. The picture in my head is of a center pipe carrying the air and a larger pipe surrounding the whole thing full of water. the water could be circulated by convection through a radiator,or even your engine coolant could be pumped through it.

Hi Handy

This kind of heat exchanger has already been made with lead (instead of water) I will try to find information on this technology if you are interested

I brushed an inch of snow off of the gasifier before opening it this morning. The encouraging thing for me is to find the nozzle in the same condition as it appeared looking into the opening when it melted. After shutting down there was no extra meltdown caused by lack of airflow.

Double ended aluminum nozzle at 1400 C.

I ordered a replacement tube so I can run another test. I look forward to seeing how the reaction temperature is affected by water flowing through the nozzle. I wonder how much water will be needed keep water or excess steam flowing out of the air inlets.

I would like to see the lead heat exchanger info if you can find it. Thank you.