Max. It is after midnight here so I don’t have time tonight to draw another picture with the changes you have stated. If I don’t have to shovel snow in the morning, I would like to send another drawing. I’m not into charcoal very much — still working on the changes to my gasifier— but when ever you post information such as this, I try to make a drawing of it for my own clarification. I know how you hate for me to ask questions, so I will get a drawing off with what I understand, and you can make comments or ignore it. TomC

Hi Max,

As long as the “to be reduced’s” are passing thru a sufficient layer glowing carbon, with sufficient dwell time/contact time/ transition time, then i don’t see any problem, hence this idea of yours even might be the best idea ever.

Max,

Thanks so much for trying again to help us see the possibility of keeping our nozzles out of the white-glowing char. My very first charcoal gasifier was a Kalle style with a coaxial gas outlet. It worked great, but he nozzle did get oxidized away quite rapidly. If I had added your funnel, the nozzle would have been protected.

If I understand this correctly, when adding a protective funnel the diameter of the nozzle needs to be matched fairly closely to the load in order to keep the air velocity high enough to carve the necessary “bottle cavity” with adequate glowing char around the bottle neck to reduce the CO2 to CO.

This conversation reminds me of your advice a few years ago to use a dog house over horizontal nozzles for the same protective effect.I assume that a horizontal nozzle with a “doghouse” would be a little more forgiving about nozzle diameter because the CO2 would always be passing through glowing char at the outer peak of the doghouse roof even when there was not enough velocity to carve out a deeper bottle shape cavity.

Hi Tom

I greatly appreciate your drawings that interprets Max’s information.

They often help me understand.

Thanks Thierry

Hi, Tom!

23. of November 2016

I have not made any changes; only different perceptions have come and gone!

I remember that as a “bird house” Bruce.![]()

Hi, Bruce!

23. of November 2016

The inside of the air-nozzle-tip is best, if it is made with trumpet-profile to accelerate the air progressively.

Pressure difference over the nozzle ~2 – 10" H2O makes good to start with…

The bottleneck is like the female nozzle in an injector, there is only speed, the pressure builds up lower down.

Also, the bottleneck surface is O-rich, reduction takes mainly place lower down and in the bottle sides, where the char is tighter.

Yes, the “doghouse” or “birdhouse” was completely dribbled away; the roof-edge was never out enough or broad enough to hinder the “back-rush” of char, assisted by the return loop gases.

Then the roof-edge was glowing away too…

The intension was to have a cutting-in sharp beam, but you saw it!

Dave, Your very simple question has caused some soul searching. The honest answer is that I am attracted to things that are weird, inexpensive, and do something useful. Nothing I have found meets all three equally and they often compete with each other. These three criteria are each met in some degree by charcoal gasification in general. An aluminum tuyere is also attractive on this basis. Using low melting temperature aluminum in a high temp environment is weird. Thick walled aluminum tube is cheaper than steel and SS. A double ended aluminum nozzle design appears to be stable at my preferred reaction temperature. Aluminum is easy to work with, transfers heat well and is less subject to catastrophic oxidation. Now with Max’s counsel about shielding nozzles from direct contact with reacting charcoal, I am even more confident that this is an acceptable if not preferable option. It is fun to try new things, and even more fun if in the end they turn out to be weird, inexpensive and useful. Thanks for asking.

Thanks Max. I’m now thinking of trying a “birdhouse” over and around horizontal nozzle holes in the side of my double-ended pass-through nozzle tube.

Hi, Bruce

23. of November 2016

Make the roof or balcony full broad to spread out the return loop gases!

Max,

Thank you for this tip.

I assume that the edge of the roof should be positioned so that a 60 degree inward slope line will clear my nozzle by 25mm/1".

Hi, Bruce!

23. of November 2016

At least! All free slopes flatten out. Return loop contributes, and shaking too.

That’s very funny.

My first thought was: -That’s my kind if thinking! ![]()

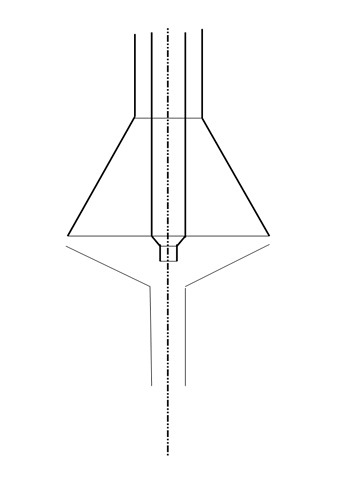

Well let me try this!!! Hope it is close to what you are telling me.

Now you just commented on a bell shaped introduction to the nozzle. Are you suggesting replaceable nozzles. The following is one of the nozzles out of my new gasifier that I believe depicts what you are telling us about nozzles in the charcoal nozzle configuration.

Apologies for the poor nozzle pictures but hope you get the idea. TomC

Hi, Tom!

24. of November 2016

From when on has char started flowing upwards where it naturally

should flow downwards?

Ar you doing “Black Magic”?

Forgot this?

Hi, Trigaux!

24. of November 2016

It was regarded as one of the best constructions on its time in Sweden.

But it needed high quality char at a primium price.

Bruce ,

Thanks for explaining your thoughts ,its always nice to be able to understand why we do certain things a certain way ,

I fully understand now why you would want to carry on testing out the aluminium , and I look forward to seeing how , if you try out Max’s idea of a inverted cone or bird house could work .

For me though steel /iron , stainless pipe is readily available as its always coming into Brains scrap yard in large amounts and when my ceramic nozzle decides to destroy itself I will be replacing it once again with the thin walled stainless pipe I used 3 months ago , yes even that old pipe I took out due to testing for other issues is still in a usable state with over 80 hours on it , the ceramic nozzle I replaced it with I made in the same way as all my others apart from when moulding it into shape I used a hand press to compact it into the mould , and so far has lasted over 3 months of regular weekly usage and would guess the life of well over 200 hours so far .

Dave

Am I guessing right that the upward arrows are indicating the “return loop”?

Hi, Bruce!

24. of November 2016

I was talking about charcoal normally flowing downward,

not about return gas!

The natural char from the silo avalanches from the bell perifery

down to the “femal nozzle” formed by the nozzle beam.

If you look “sharp” on Tom’s sketch, you see that he has put the char level inside the bell high above the periphery of the bell!!!

There is no power rising the char level inside the bell!

The char avalanches downward to the mouth of the “female nozzle” formed by the blowing beam!

Complete Black Magic!